Comprehensive Equipment Shop Manual

Product Overview

This shop manual is an essential resource for professionals working in a workshop setting, offering detailed technical information for servicing equipment. The manual is structured into clear sections to aid understanding and effectiveness in both maintenance and troubleshooting tasks.

Section Breakdown

00. Index and Foreword

The initial section provides a foreword and general information, setting the stage for all the specifics that follow.

01. Specification

This section details the specifications and technical data essential for the accurate servicing of the machine.

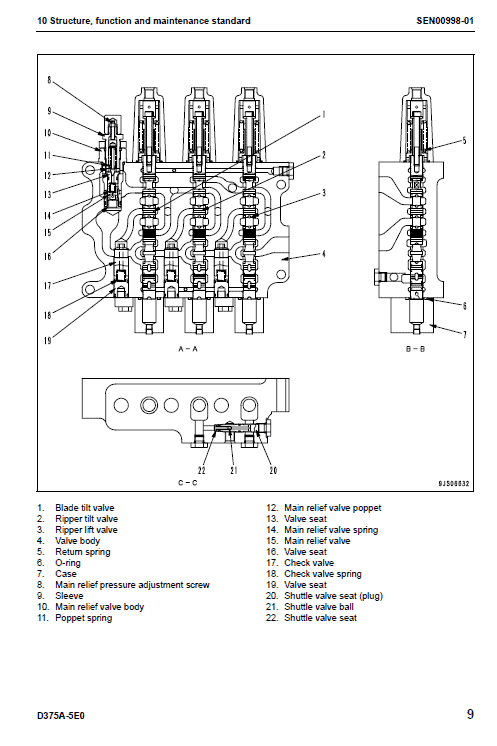

10. Structure, Function, and Maintenance Standard

- Engine and Cooling System

- Power Train

- Undercarriage and Frame

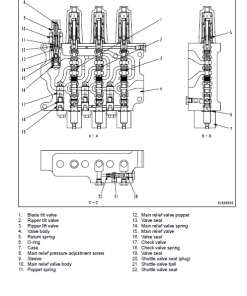

- Hydraulic System

- Work Equipment

- Cab and Attachments

- Electrical System

20. Standard Value Table

This section includes standard service values designed to assist in testing, adjusting, and troubleshooting machinery. It is used to verify standard values during testing and inform decision-making during troubleshooting efforts.

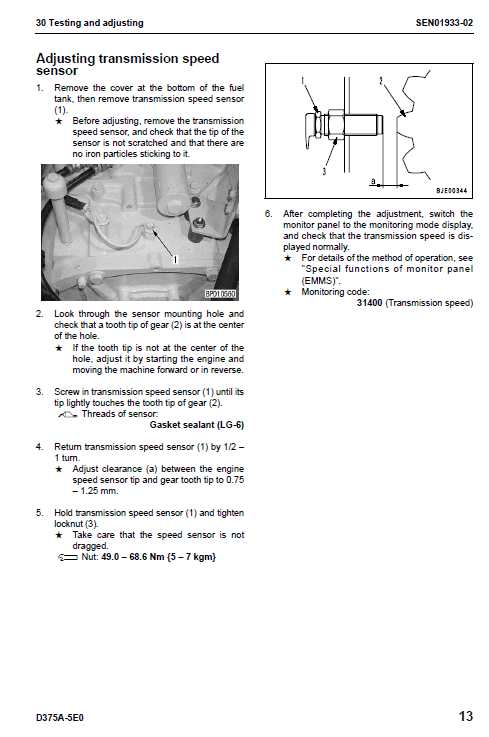

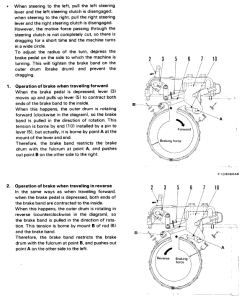

30. Testing and Adjusting

Details the measuring tools, methodologies, and adjustment techniques for various components. It is aligned with the “Standard Value Table” for consistency in standards and decision-making.

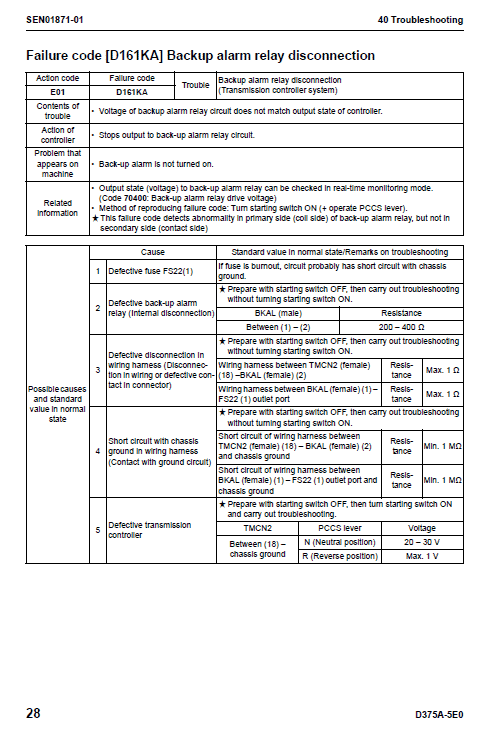

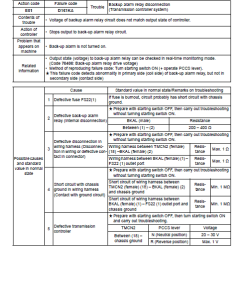

40. Troubleshooting

Troubleshooting methodologies are clearly described, including the identification and repair of faulty parts. The section is categorized by failure modes, offering cross-references to relevant volumes for comprehensive diagnosis.

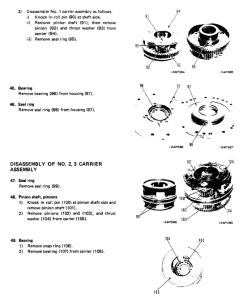

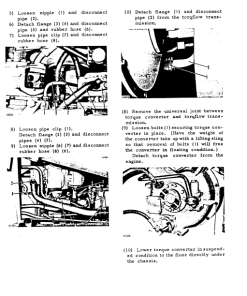

50. Disassembly and Assembly

Instructions on component removal, installation, disassembly, and assembly, complete with details on required special tools, safety precautions, and guidelines on appropriate torque, material, oil, grease, and coolant amounts.

60. Maintenance Standard

Provides maintenance standards for each component, offering detailed criteria and remedies for effective disassembly and service procedures.

80. Appendix

Covers additional equipment details that do not fit into other sections, including structure, function, testing, adjusting, and troubleshooting relevant to these supplementary components.

90. Diagrams and Drawings

Offers detailed hydraulic and electrical circuit diagrams, essential for in-depth technical understanding and servicing tasks.

Failure Codes Overview

This manual includes critical failure code information, helping identify and resolve issues related to various sensors and components. Here are some of the notable codes:

- [DK30KA] Steering potentiometer 1 disconnection

- [DK30KB] Steering potentiometer 1 short circuit

- [DK30KX] Steering potentiometer 1 input signal out of range

- [DK30KZ] Steering potentiometer 1 disconnection or short circuit

- [DK30L8] Steering potentiometer 1 analog signal disagreement

Please refer to the full manual for a complete list of failure codes and their descriptions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.