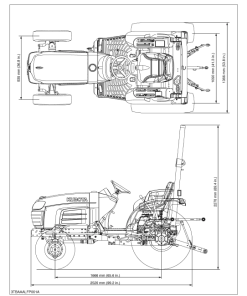

Kubota R320S, R320SB Wheel Loader Workshop Manual

$34.00

Format: PDF

Language: English

This comprehensive workshop manual contains 381 pages dedicated to the Kubota R320S and R320SB Wheel Loader. It provides detailed instructions and technical specifications to support maintenance and repair.

Kubota R320S, R320SB Wheel Loader Workshop Service Manual

Product Overview

The Kubota R320S and R320SB Wheel Loader Workshop Service Manual is an essential PDF guide designed for maintaining and repairing your Kubota wheel loader. With 381 pages of comprehensive content, this manual provides detailed instructions to help you understand the machine’s construction and functions, ensuring efficient and safe disassembly and assembly of your equipment.

Available for the Kubota Wheel Loader models R320S and R320SB, this manual is a valuable resource for both professional mechanics and dedicated owners who are keen on performing routine maintenance themselves. The manual is published under the code RY911-21080 and is presented in English for ease of use.

Key Features

- Publication: RY911-21080

- Format: PDF

- Language: English

- Total Pages: 381

- Extensive coverage of all major systems including engine, hydraulic, and electrical systems

Benefits

- Improve performance with in-depth maintenance guidelines

- Empowers owners to conduct regular maintenance, saving on repair costs

- Comprehensive information on safely and efficiently assembling and disassembling machinery

Usage Recommendations

- Familiarize yourself with the machine’s construction and functions before proceeding with maintenance or repairs.

- Consult your KUBOTA dealer for any complex issues or if you need additional support.

- Adhere to specified procedures for safe and efficient operations to prevent any damage or hazards.

Table of Contents

- Information

- General

- Engine

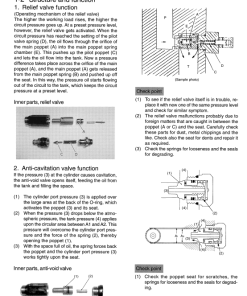

- Hydraulic System

- Power Train

- Brakes

- Steering

- Front Loader

- Frame

- Electrical System

- Backhoe

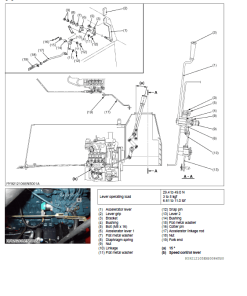

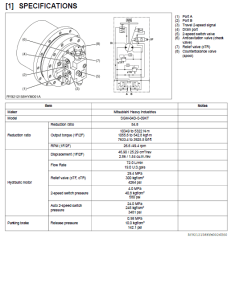

Measurement of Hydraulic Device Performance

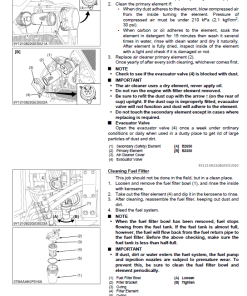

The manual includes detailed procedures to measure hydraulic device performance. Below is a step-by-step guide:

- Jack up the vehicle and support both axles with jack stands. Ensure the tires do not touch the ground.

- After disconnecting the hoses between the LST pump and the LST motor, attach hoses to the flow meter as indicated by the accompanying diagram.

- Open the loading valve of the flow meter, start the engine at idle speed, and ensure there are no leaks.

- Increase the engine to max RPM, and with no load, measure the flow and engine RPM.

- Gradually close the loading valve to exert the rated load pressure on the pump, then measure the flow and engine RPM.

Note: Exercise caution to avoid mistaken hose connections or travel direction to prevent damage to the flow meter, LST pump, and/or motor.

Warning: Ensure no one approaches the machine during testing for safety reasons.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.