Kobelco K907D and K907DLC Excavator Service Manual

$34.00

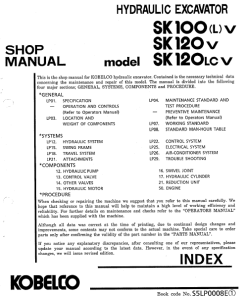

Discover the comprehensive Kobelco K907D and K907DLC Excavator Technical Manual. This detailed guide is available in PDF format, features 540 pages of in-depth information, and is written in English. Reference publication number: S5LN0004E-01.

Kobelco K907D and K907DLC Excavator Service Manual

Product Overview

The Kobelco K907D and K907DLC Excavator Service Manual is an essential resource for repair specialists tasked with servicing these specific excavator models. This comprehensive guide contains 540 pages of detailed instructions, specifications, and troubleshooting tips. It is available in PDF format and is published in English under Publication S5LN0004E-01.

Learn more about Kobelco Excavators

Key Features

- Detailed specifications for K907D and K907DLC models

- Comprehensive maintenance guidelines

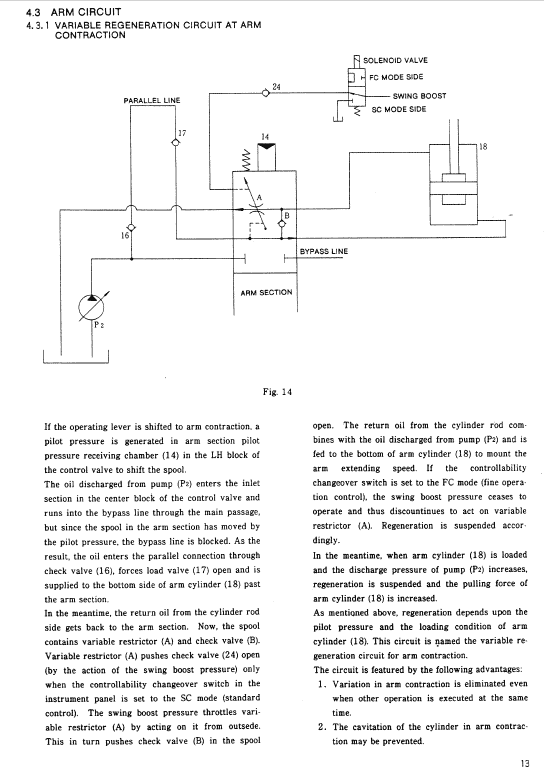

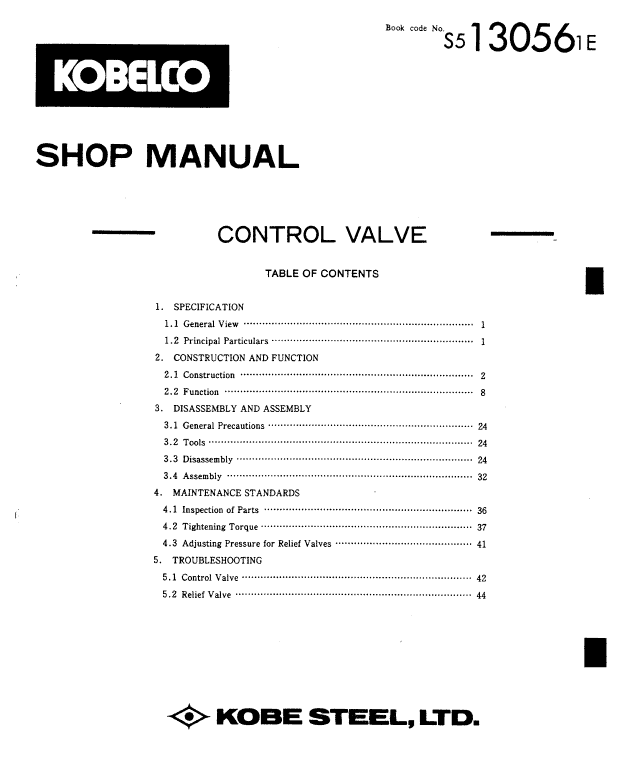

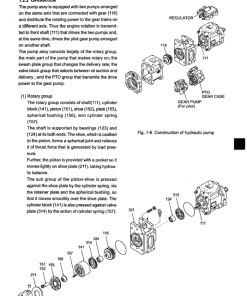

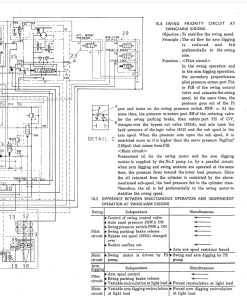

- In-depth system diagrams and descriptions

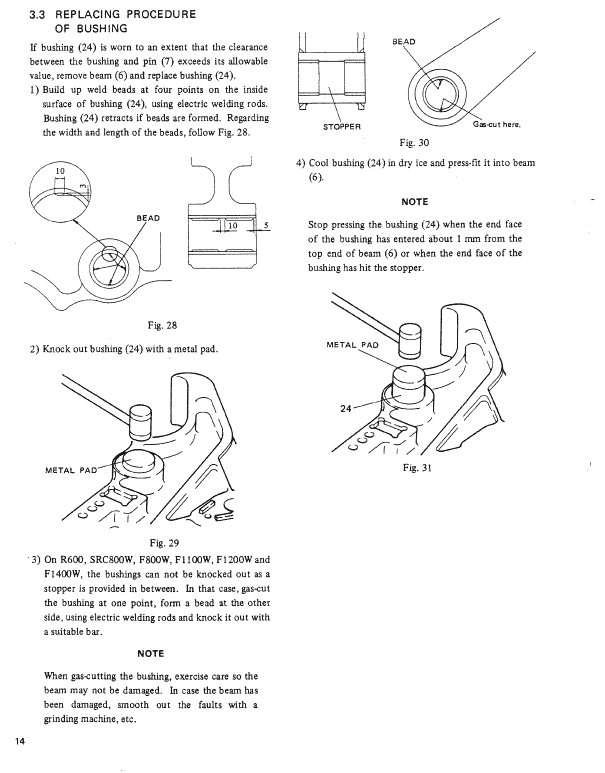

- Instructions for disassembling and reassembling components

- Troubleshooting procedures for common issues

Benefits

- Assists repair specialists in understanding complex systems

- Enhances safety and efficiency during maintenance and repairs

- Reduces downtime by providing thorough fault location instructions

- Improves the longevity of your equipment through proper care

Usage Recommendations

- Read and understand all warning plates and decals on the machine before operation or maintenance.

- Consult the manual even if you are familiar with excavator technology.

- Always use proper lifting procedures and safety precautions.

- Pay careful attention when removing caps or plugs to avoid splashes from hot or pressurized fluids.

- Use the manual as a reference for expert repairs and routine maintenance.

Kobelco K907D and K907DLC Preface Instructions

It is crucial to read and comprehend all warning plates and decals on your machine before performing any operations, maintenance, or repairs. This manual is specifically crafted for repair specialists who might be unfamiliar with certain systems of these excavators. Exercise great caution and adhere closely to the guidelines presented.

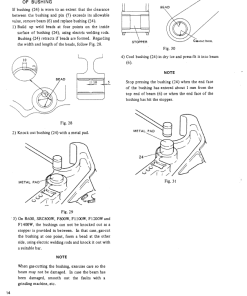

Always review the Shop Manual thoroughly before commencing any repair work. Use proper lifting techniques when removing components and be vigilant when dealing with filler caps and plugs, especially immediately after the machine has been in use, due to potential exposure to hot and pressurized fluids.

Whether you’re an experienced mechanic or new to construction machinery, the Shop Manual serves as an excellent resource for ensuring precise and expert repairs.

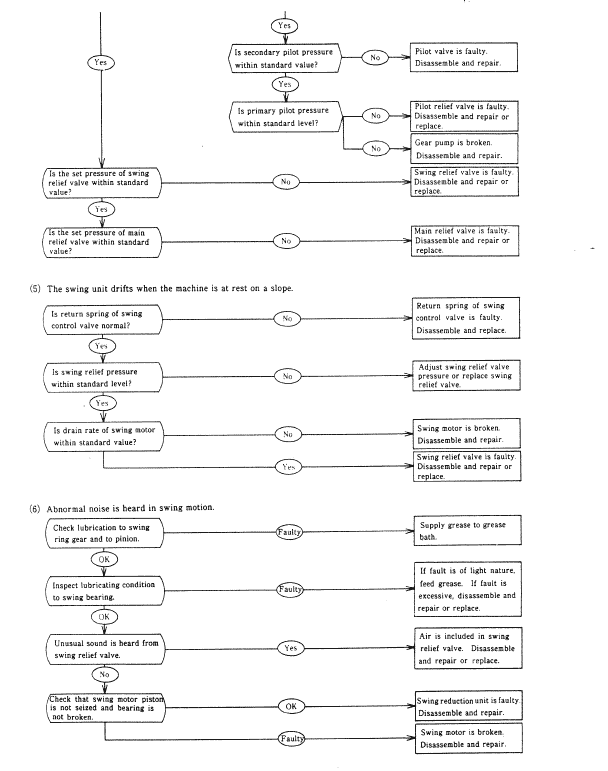

Fault Location

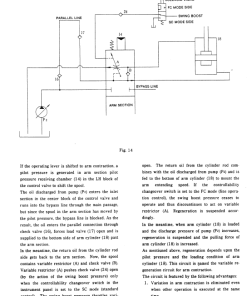

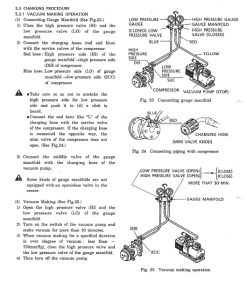

Identifying faults in the pump system can be challenging due to components like regulators and auxiliary pumps. Below are some steps to help locate issues:

- Checking Filters and Drain Oil: Inspect the filter for unusual quantities of impurities. A high presence of metallic particles suggests shoe failure.

- Abnormal Vibration and Sound: Identify abnormal vibrations or noises, which may indicate cavitation or pump damage.

- In Case of Two Pumps Used: Swap pipelines between pumps to determine if issues are with the pumps or downstream components.

- Measuring Pressure at Different Points: If control issues arise, measure pressures at various points instead of opening the system prematurely for accurate fault identification.

Only logged in customers who have purchased this product may leave a review.

Related products

Excavator

Reviews

There are no reviews yet.