Cylinder Block Inspection Manual

Product Overview

This manual provides a comprehensive guide for inspecting and maintaining the cylinder block of your machinery. By following these detailed steps, you can ensure optimal performance and longevity of your equipment. It is crucial to regularly inspect essential components to prevent damage and maintain operational efficiency.

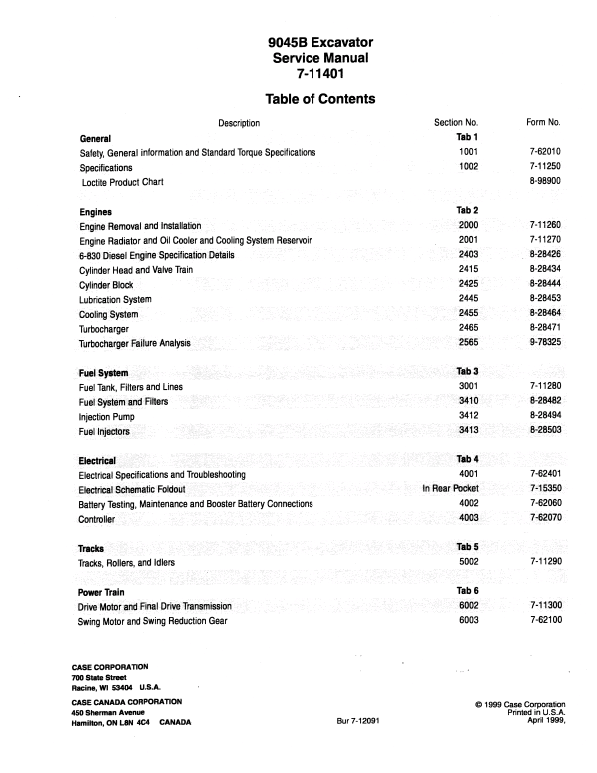

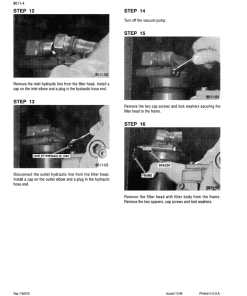

Inspection Process

- Cleaning: Clean all parts using a suitable cleaning solvent and dry them with low-pressure compressed air.

- Spring Inspection: Examine springs (2, 13, 25, and 29) for any signs of cracks, breaks, distortion, bends, or permanent setting. Replace defective springs.

- Cylinder Block Inspection: Check the cylinder block (4) for pitting, scoring, grooves, cracks, or flaking. Inspect piston bores and splines for similar issues and wear. Replace the cylinder block if needed.

- Retainer Holder Check: Investigate the retainer holder (7), retainer plate (9), and valve plate (24) for damage such as pitting or cracks. Replace as necessary.

- Piston Examination: Examine pistons (8 and 14) for any defects or damage including scoring, grooves, or flaking. Replace defective pistons.

- Bearings Assessment: Inspect bearings (11 and 36) for outer race flaking and rough rotation. Examine for wear or other damage, and replace if needed.

- Steel Balls Inspection: Check steel balls (12) for defects and wear. Replace if any issues are noted.

- Shaft Inspection: Examine the shaft (15) for cracks, breaks, or damage. Replace if any defects are found.

- Swash Plate Review: Inspect the swash plate (16) and ensure there is no wear or damage at ball contact areas.

- Disk Plates Check: Look for grooves or flaking on the disk plates (18) and replace as needed.

- Friction Plates Inspection: Check friction plates (19) for structural integrity issues like cracks or distortions.

- Brake Piston Assessment: Inspect the brake piston (20) for any potential damage.

Key Features

- Step-by-step inspection process

- Comprehensive guidelines for various parts

- Easy to follow, systematic approach

Benefits

- Ensures machinery operates at optimal performance

- Helps identify and rectify potential issues early

- Prolongs the lifespan of key machinery components

Usage Recommendations

- Regularly perform inspections to maintain equipment integrity.

- Replace any parts showing signs of wear or damage immediately.

- Consult this manual as a reliable reference during maintenance checks.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$33.00

$33.00

$32.00

$34.00

$35.00

Reviews

There are no reviews yet.