Hydraulic Pump Installation Manual

Product Overview

This manual provides detailed instructions for installing and preparing a hydraulic pump for operation. Whether you’re replacing components or installing a new system, follow these steps to ensure proper setup and functionality.

Table of Contents

- General

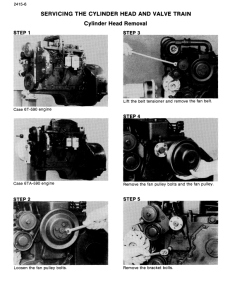

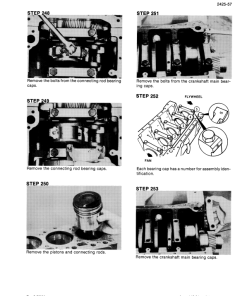

- Engines

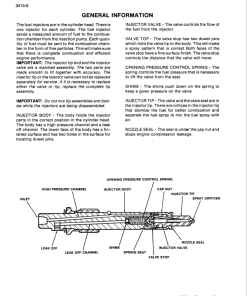

- Fuel System

- Electrical

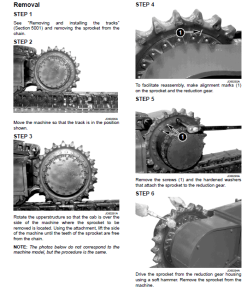

- Track and Suspension

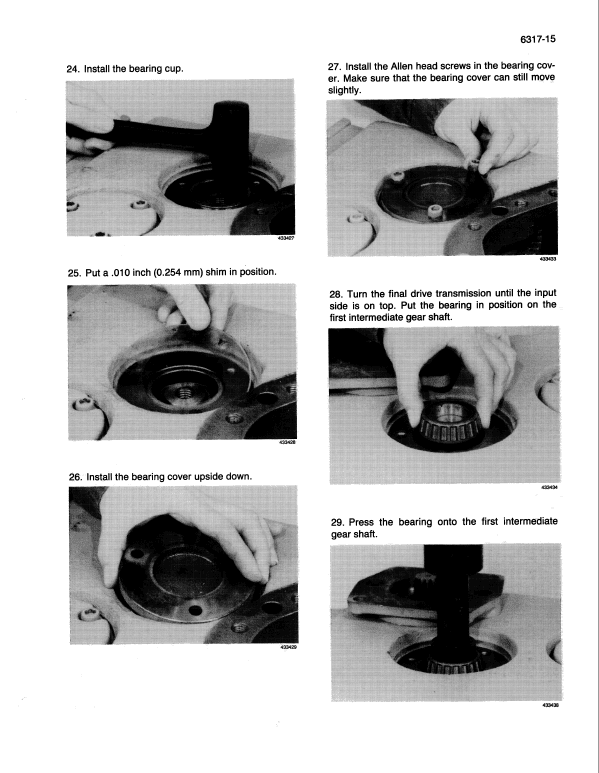

- Power Train

- Brakes

- Hydraulics

- Mounted Equipment

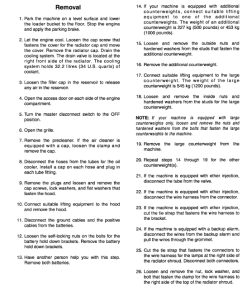

Installation Instructions

- Attach suitable lifting equipment to the hydraulic pump and raise it into position.

- Align the drive shaft splines of the hydraulic pump with the drive plate on the engine by rotating the drive shaft.

- Secure the hydraulic pump against the engine using cap screws and lock washers.

- Tighten the cap screws to 65 to 85 pound-feet (88 to 115 Nm, 9 to 16 kg/m).

- Detach the outlet hoses from the hydraulic pump fittings.

- Connect the inlet tubes to the hydraulic pump.

- Fasten the clamps on the inlet tubes securely.

- Tighten the split flange cap screws to 55 to 65 pound-feet (74 to 88 Nm, 8 to 9 kg/m).

- Refer to Section 8201 and fill the reservoir with approximately 19 U.S. gallons (72 liters) of oil.

- If the gears or gear housings were replaced, prepare the hydraulic pump for use as indicated on page 8200-0.

- Start the engine and let it idle for two minutes.

- Increase the engine speed to full throttle and operate the controls to extend and retract all cylinders to remove air from the hydraulic system.

- Check the oil level in the reservoir and add oil as needed, according to Section 8201.

- With the engine at full throttle, operate the tool control. Hold the control in the power position for 15 seconds after the tool stops moving, then release it for 30 seconds. Repeat this three times.

- Stop the engine and inspect for any oil leaks.

Benefits

- Detailed step-by-step instructions to ensure correct installation.

- Universal guidelines suitable for various hydraulic pump setups.

- Helps prevent common errors that could lead to operational failures.

Usage Recommendations

- Ensure all tools and equipment used are rated for the load and properly maintained.

- Follow the specified torque values to avoid damage.

- Regularly check for leaks and maintain fluid levels as part of routine maintenance.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.00

$34.00

$32.00

$34.00

$34.00

$34.00

Reviews

There are no reviews yet.