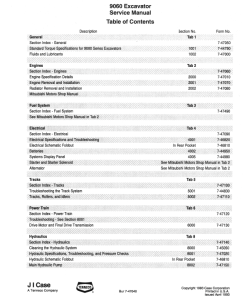

Case 9060 Excavator Service Manual

$34.00

This comprehensive Case 9060 Excavator Service Manual includes everything you need to maintain your equipment with ease.

Product Details:

- Pages: 653

- Brand: Case

- Model: 9060

- Type: Excavator

- Manual Included: Service Manual

- Publication Number: 7-47040 (April 1999)

- Language: English

- Format: PDF

Ensure the longevity and reliability of your Case 9060 Excavator with this user-friendly manual. Download now for detailed instructions.

Machine Maintenance and Track Adjustment Guide

Product Overview

This guide provides essential information for maintaining and adjusting your machine tracks. It includes detailed procedures to ensure optimal performance on various surfaces through precise track tension adjustments. Ideal for technicians and operators seeking to enhance machine efficiency and prolong equipment life.

Table of Contents

- Specification

- Maintenance

- System

- Disassembling

- Troubleshooting

- Engine

- Installation Procedures for Optional Attachments

Key Features

- Comprehensive track tension adjustment instructions

- Specific guidance for hard and soft surface operations

- Step-by-step procedures for accurate measurement and adjustment

Benefits

- Ensures optimal machine performance on various terrains

- Reduces wear and tear on machine components

- Enhances safety and efficiency during machine operation

Usage Recommendations

Track Tension Adjustment:

- Regularly check track tension, adjusting as needed based on the operating surface.

- For hard surfaces, tighten the tracks for enhanced stability and control.

- For soft surfaces, loosen the tracks to prevent excessive friction and wear.

Adjustment Procedure:

- Park the machine on a hard, level surface. Position the excavator cab over the track to be adjusted.

- Place wood blocks under the tool and lower it until the track is slightly elevated, ensuring the track shoes do not touch the ground.

- Measure the track deflection between the third and fourth track rollers, ensuring it is between 2.8 to 3.6 inches (70 to 91 mm).

- To increase tension:

- Clean the grease fitting on the track adjustment cylinder.

- Carefully inject grease until the desired track tension is achieved.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.00

$34.00

$35.00

$35.00

$34.00

Reviews

There are no reviews yet.