Product Manual: Essential Checks for Noise Control

Product Overview

This guide provides essential noise control checks for machinery to ensure optimal operation and reduced noise levels. Regular adherence to these procedures supports effective machinery function and helps prevent long-term damage.

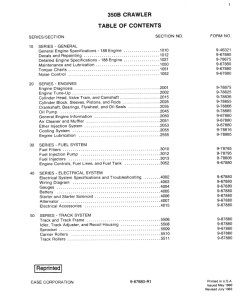

Table of Contents

- General

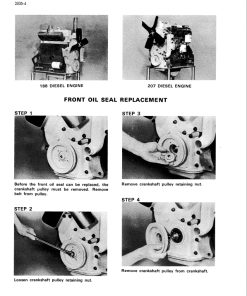

- Engines

- Fuel System

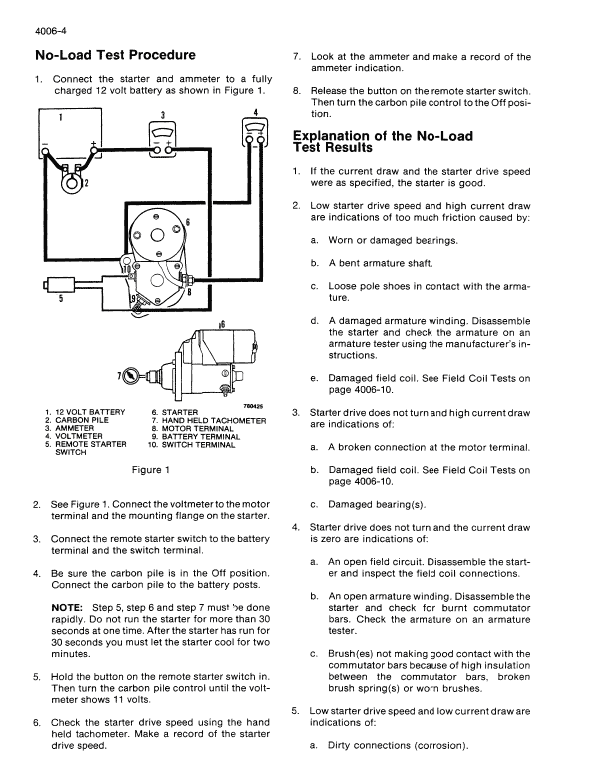

- Electrical System

- Track System

- Power Train

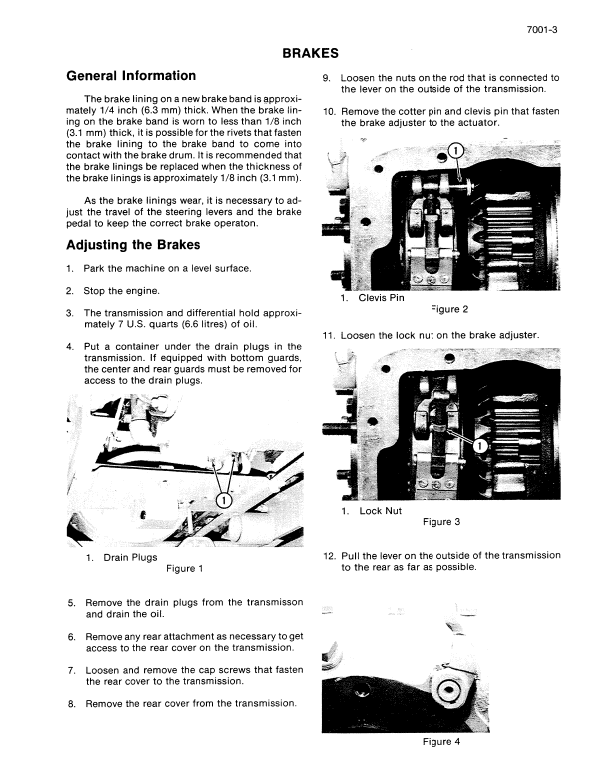

- Brakes

- Hydraulic System

- Mounted Equipment

Key Features

- Comprehensive noise control evaluation procedures.

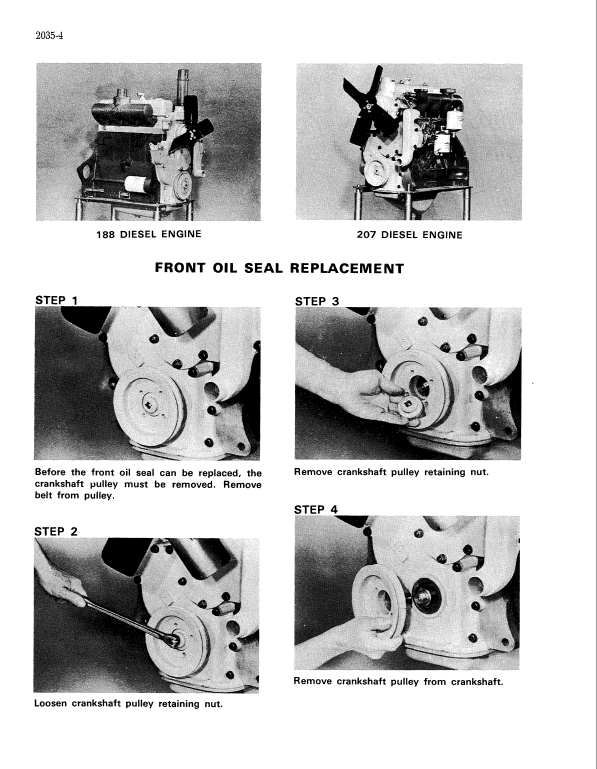

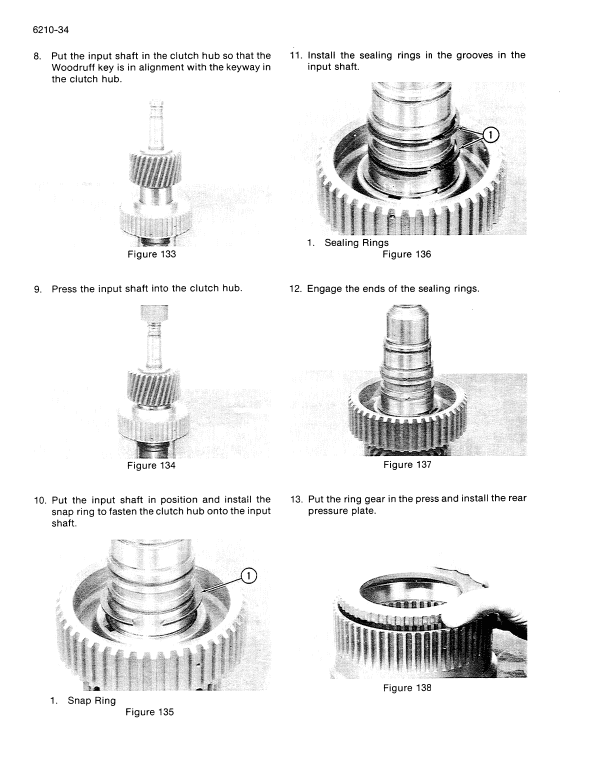

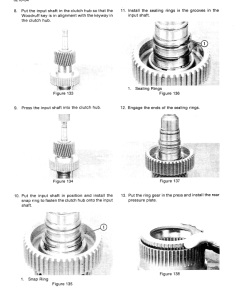

- Step-by-step guide to checking and securing vital parts.

- Detailed instructions for inspecting and replacing damage-prone components.

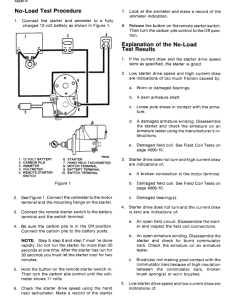

- Specific guidelines for assessing engine speed and vibration levels.

Benefits

- Ensures machinery operates quietly and efficiently.

- Prevents damage due to loose or missing components.

- Identifies potential issues early, minimizing costly repairs.

- Improves overall workplace safety by reducing noise pollution.

Usage Recommendations

- Fasten Loose Components: Ensure all nuts, bolts, sheet metal, floor plates, and guards are tightly secured.

- Inspect Pads: Check and replace any damaged or missing pads to maintain proper noise insulation.

- Check Noise Insulators: Regularly examine noise insulators such as engine mounts and hydraulic tube insulators. Replace as needed.

- Monitor Engine Speed: Verify maximum engine speed without load as per Section 3012 instructions.

- Assess Vibration: Gradually increase engine speed from low idle to full throttle at 200 rpm intervals. Investigate and resolve any excessive vibration.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.00

$34.00

$35.00

$32.00

Reviews

There are no reviews yet.