-

×

Hyster E30B, E40B, E50B, E60BS Electric Forklift Truck B108 Series Repair Manual (EU)

$35.00

Hyster E30B, E40B, E50B, E60BS Electric Forklift Truck B108 Series Repair Manual (EU)

$35.00 -

×

Liebherr D9508 A7 Engine Service Manual

$27.00

Liebherr D9508 A7 Engine Service Manual

$27.00 -

×

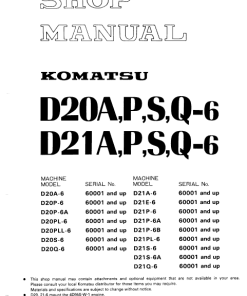

Komatsu D20PLL-6, D20S-6, D20Q-6, D21E-6 Dozer Service Manual

$32.00

Komatsu D20PLL-6, D20S-6, D20Q-6, D21E-6 Dozer Service Manual

$32.00 -

×

New Holland W50 Wheeled Loader Service Manual

$34.00

New Holland W50 Wheeled Loader Service Manual

$34.00 -

×

Liebherr R924 and R924 Tier 3 Compact Excavator Service Manual

$33.00

Liebherr R924 and R924 Tier 3 Compact Excavator Service Manual

$33.00 -

×

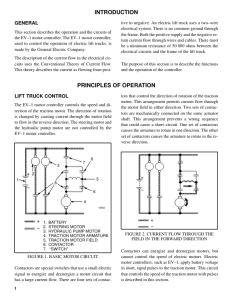

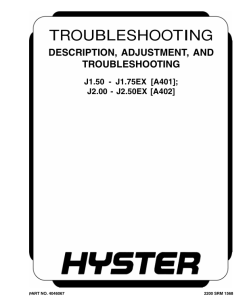

Hyster J1.50EX, J1.75EX, J2.00EX, J2.50EX Electric Forklift A401 Series Repair Manual

$25.00

Hyster J1.50EX, J1.75EX, J2.00EX, J2.50EX Electric Forklift A401 Series Repair Manual

$25.00 -

×

Hyster J2.00XM, J2.50XM, J3.00XM, J3.20XM Electric Forklift Truck A216 Series Repair Manual

$49.00

Hyster J2.00XM, J2.50XM, J3.00XM, J3.20XM Electric Forklift Truck A216 Series Repair Manual

$49.00 -

×

Hyster E45XN, E50XN, E55XN, E60XN, E65XN, E70XN Electric Forklift Truck A268 Series Repair Manual

$49.00

Hyster E45XN, E50XN, E55XN, E60XN, E65XN, E70XN Electric Forklift Truck A268 Series Repair Manual

$49.00 -

×

Manitou MRT-X 2150, 2550 Privilege Plus ST3A S2 Telehandler Repair Service Manual

$45.00

Manitou MRT-X 2150, 2550 Privilege Plus ST3A S2 Telehandler Repair Service Manual

$45.00 -

×

Hyster J40Z, J50Z, J60Z Electric Forklift Truck A416 Series Repair Manual (USA)

$45.00

Hyster J40Z, J50Z, J60Z Electric Forklift Truck A416 Series Repair Manual (USA)

$45.00 -

×

John Deere 450D, 455D Crawler Bulldozer Loader Technical Manual

$38.00

John Deere 450D, 455D Crawler Bulldozer Loader Technical Manual

$38.00 -

×

Kubota KH66, KH91, KH101, KH105 Excavator Workshop Manual

$32.00

Kubota KH66, KH91, KH101, KH105 Excavator Workshop Manual

$32.00 -

×

Hyster J170XNL, J175XNL, J190XNL Electric Forklift A250 Series Repair Manual

$49.00

Hyster J170XNL, J175XNL, J190XNL Electric Forklift A250 Series Repair Manual

$49.00 -

×

New Holland E10SR Mini Excavator Service Manual

$34.50

New Holland E10SR Mini Excavator Service Manual

$34.50 -

×

OM PIMESPO Modo 12 Order Picker Workshop Repair Manual

$26.00

OM PIMESPO Modo 12 Order Picker Workshop Repair Manual

$26.00 -

×

New Holland E140CSR Excavator Service Manual

$36.00

New Holland E140CSR Excavator Service Manual

$36.00 -

×

New Holland E200SR Excavator Service Manual

$36.00

New Holland E200SR Excavator Service Manual

$36.00 -

×

Case 21D, 121D, 221D and 321D Wheel Loader Service Manual

$34.00

Case 21D, 121D, 221D and 321D Wheel Loader Service Manual

$34.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (DAC00001 and up)

$50.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (DAC00001 and up)

$50.00 -

×

Case CX20B, CX22B Excavator Service Manual

$33.00

Case CX20B, CX22B Excavator Service Manual

$33.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (ASN00001 and up)

$50.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (ASN00001 and up)

$50.00 -

×

Kubota KX057-4, U55, U55-4 Excavator Workshop Service Manual

$34.00

Kubota KX057-4, U55, U55-4 Excavator Workshop Service Manual

$34.00 -

×

JCB 3000 XTRA Series Fastrac Service Manual

$35.00

JCB 3000 XTRA Series Fastrac Service Manual

$35.00 -

×

JCB FM25 Mower Service Manual

$30.00

JCB FM25 Mower Service Manual

$30.00 -

×

OM Pimespo XOP10 and XOP10ac Series XOP Lift Workshop Repair Manual

$27.00

OM Pimespo XOP10 and XOP10ac Series XOP Lift Workshop Repair Manual

$27.00 -

×

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00

JCB AGCO OEM Transmission ML180 T702 Manual

$30.00 -

×

OM PIMESPO Modo 1,2,3 Series 014 Mid and High-lift Order Pickers Workshop Repair Manual

$27.00

OM PIMESPO Modo 1,2,3 Series 014 Mid and High-lift Order Pickers Workshop Repair Manual

$27.00

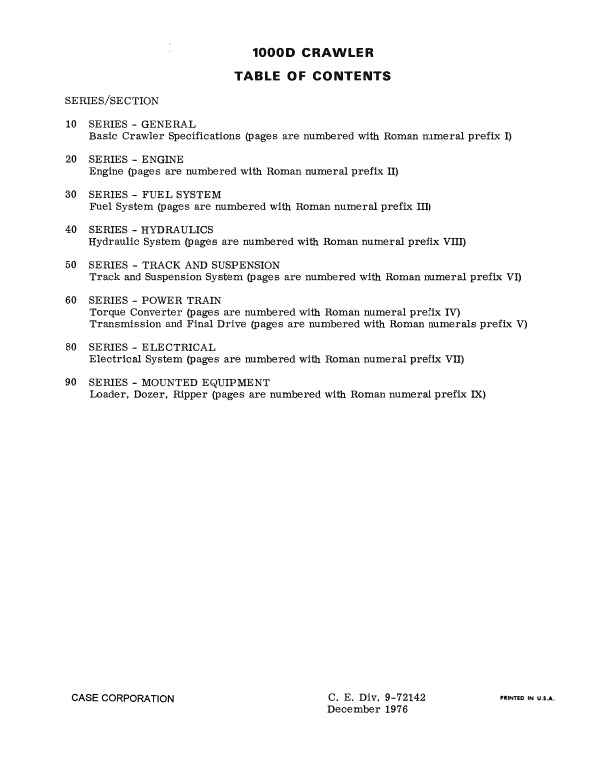

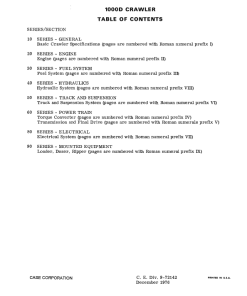

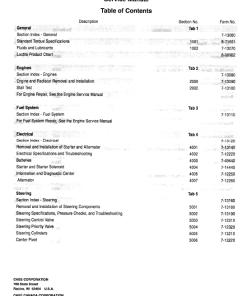

Case 1000D Crawler Dozer Service Manual

$25.00

This comprehensive service manual for the Case 1000D Dozer provides detailed guidance over 261 pages. It’s an essential resource for maintenance and repairs.

Specifications

Brand: Case

Model: 1000D

Type: Dozer

Manuals: Service Manual

Publication Numbers: 9-72142 (Dec 1976)

Language: English

Format: PDF

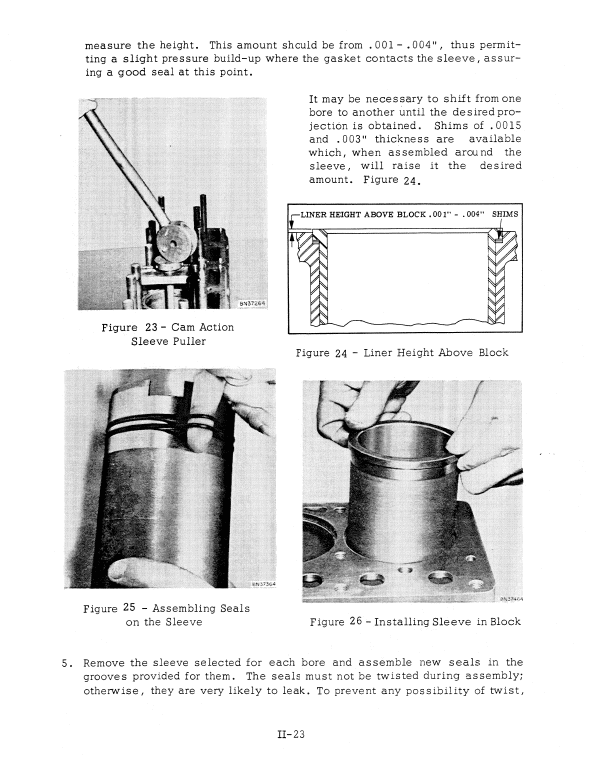

Case Crawler Maintenance Manual: Fuel System Overview

Product Overview

This manual extract provides essential instructions for maintaining the fuel system of the Case Crawler. The fuel system features a comprehensive three-stage filtering process designed to ensure optimal fuel cleanliness and efficiency. By following these guidelines, users can effectively manage and maintain the fuel system, reducing downtime and enhancing machine performance.

Key Features

- Three-Stage Filtering System: Ensures thorough removal of contaminants with a sequence of filters.

- Primary Filter: Metal-edge, cleanable filter that captures heavier particles.

- Secondary Filter: Contains a replaceable element for filtering finer abrasives.

- Final Stage Filter: Sealed, non-cleanable filter positioned before the injection pump, effective for particles as small as 2 microns.

- Vacuum Gauge Fitting: Equipped with a tee fitting on the pump inlet to measure vacuum levels and check filter efficiency.

Benefits

- Optimized Fuel Flow: Reduces the risk of clogging and ensures smooth operation.

- Prolonged Filter Life: Proper maintenance can significantly extend the interval between filter replacements.

- Improved Equipment Performance: Maintains engine efficiency and reduces the likelihood of fuel-related issues.

Usage Recommendations

- Monitor the vacuum gauge regularly. If it shows a reading of 10″ or more, it indicates restricted fuel flow.

- Clean the primary filter when high vacuum readings are observed. If issues persist, replace the secondary filter element.

- Only replace the final stage filter if problems continue after servicing the primary and secondary filters.

- Routine maintenance of the primary and secondary filters reduces the need for frequent final filter replacements.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$35.00

$34.50

$33.00

$33.50

$33.00

Reviews

There are no reviews yet.