Service Manual: Final Drive Removal Instructions

Product Overview

This section of the service manual provides detailed instructions for removing a final drive assembly from your machinery. Follow these steps carefully to ensure a safe and effective removal process.

Table of Contents

- General

- Engines

- Fuel System

- Electrical

- Track System

- Power Train

- Brakes

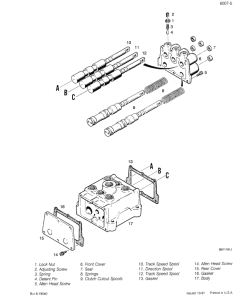

- Hydraulic System

- Mounted Equipment

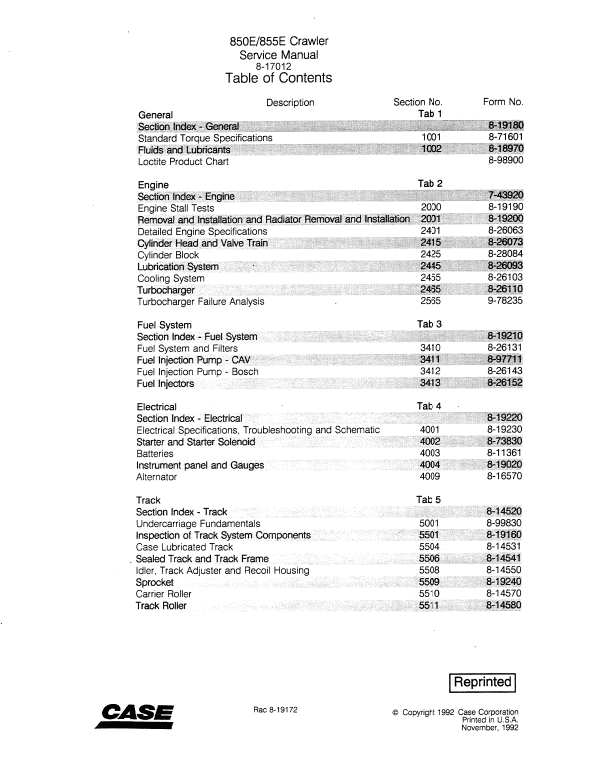

Instructions for Removing a Final Drive

-

Initial Preparations:

- Refer to the appropriate section in this service manual to begin removing the rear attachment.

- If installed, remove the bottom guard for the final drive.

- Detach any necessary mounting arms and frames.

- Sprocket Removal: Align with instructions provided in Section 5509 to remove the sprocket from the final drive.

-

Stabilization:

- Place a jack under the transmission for support during the final drive removal. Ensure not to lift the transmission with the jack.

- Fastener Removal: Loosen and remove the cap screws securing the final drive to both the seat frame and main frame.

- Nuts Removal: Loosen and remove the self-locking nuts that attach the final drive to the transmission.

-

Lifting Tool Installation:

- Secure lifting tool CAS-1553 to the sprocket shaft.

- Tighten the clamps firmly against the housing before tightening the nut.

- Lifting Equipment Connection: Attach lifting equipment to the tool, then leverage using a long pipe at the tool’s end.

-

Final Drive Removal:

- Extract the final drive from the machine. If necessary, apply gentle force to the bottom front and rear to break the seal between the final drive and the transmission.

- Utilize a prybar as needed to facilitate removal.

Usage Recommendations

- Ensure all removal steps are performed on a stable, flat surface to maintain safety.

- Use proper safety gear, including gloves and eyewear, throughout the process.

- This process should be conducted by experienced technicians familiar with the machinery’s service manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$33.00

Reviews

There are no reviews yet.