Hydraulic System Manual: Pressure Test Procedure

Product Overview

This manual provides detailed instructions for performing a pressure test on your hydraulic system. It is designed for technicians who need to verify the system’s efficiency and ensure optimal performance. Follow the steps carefully to maintain the longevity and safety of your machinery.

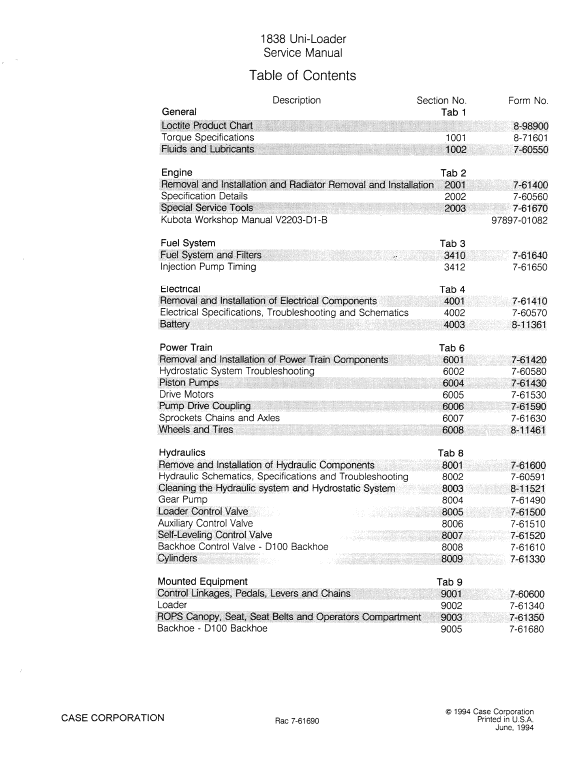

Table of Contents

- General

- Engines

- Fuel System

- Electrical

- Power Train

- Brakes

- Hydraulics

- Mounted Equipment

Key Features

- Comprehensive hydraulic system testing guide.

- Detailed procedure for pressure and efficiency evaluation.

- Recommendations for safe equipment handling during testing.

Benefits

- Ensures hydraulic system operates within optimal pressure range.

- Helps identify and rectify issues with pressure and efficiency.

- Improves machine reliability and performance.

Usage Recommendations

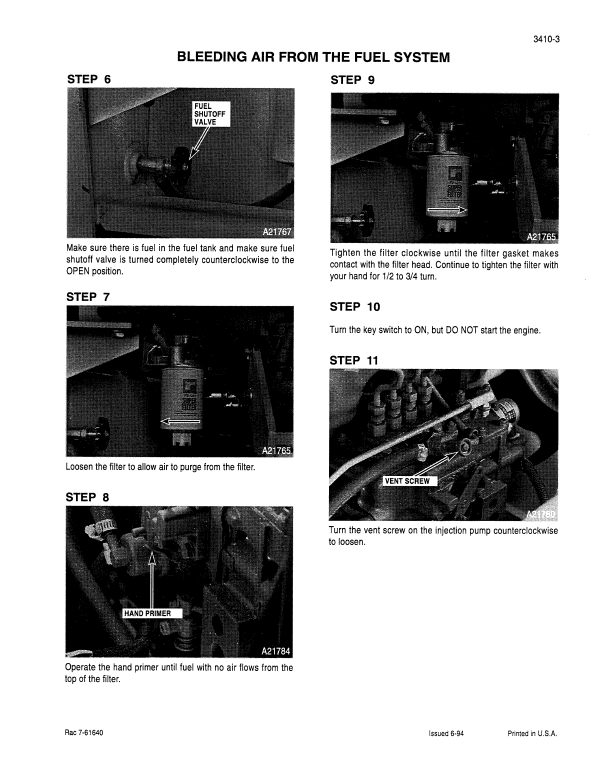

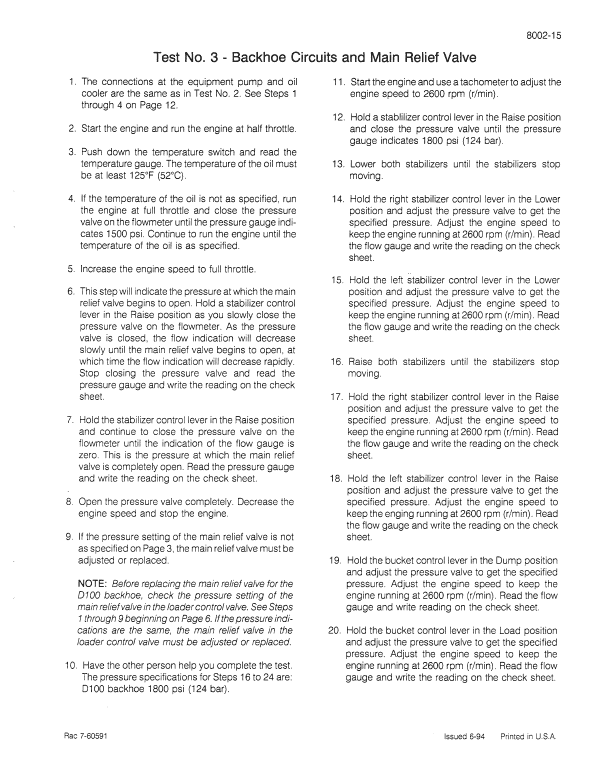

- Step 1: Connect a 400 PSI (28 bar) pressure gauge to the test port at the hydraulic filter outlet.

- Step 2: Run the engine and heat the oil to at least 125u00b0F (52u00b0C) by cycling the bucket control lever as explained.

- Step 3: Keep the engine at full throttle, record the pressure and ensure it’s between 130 to 150 PSI (9.0 to 10.3 bar).

- If pressures are correct, read further instructions on Section 8002, Page 6 for next steps.

- Follow additional procedures to inspect components, ensure hydraulic line routing, and adjust the charge relief valve if needed.

- For safety, raise the machine on supports when performing tests with the engine running to mitigate risks associated with parking latch failure.

- Use a flow meter to verify gear pump efficiency as described in Section 8002.

For more detailed guidance and troubleshooting, please refer to the full manual. Ensure all safety precautions are taken during the testing process to protect both the operator and the machine.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.00

$34.00

$32.00

$34.00

$34.00

Reviews

There are no reviews yet.