Radiator Removal and Installation Guide

Product Overview

This comprehensive guide provides detailed instructions for the removal and installation of radiators in heavy machinery. It is designed to assist technicians in safely and efficiently handling the radiator system, ensuring optimal machine performance and longevity.

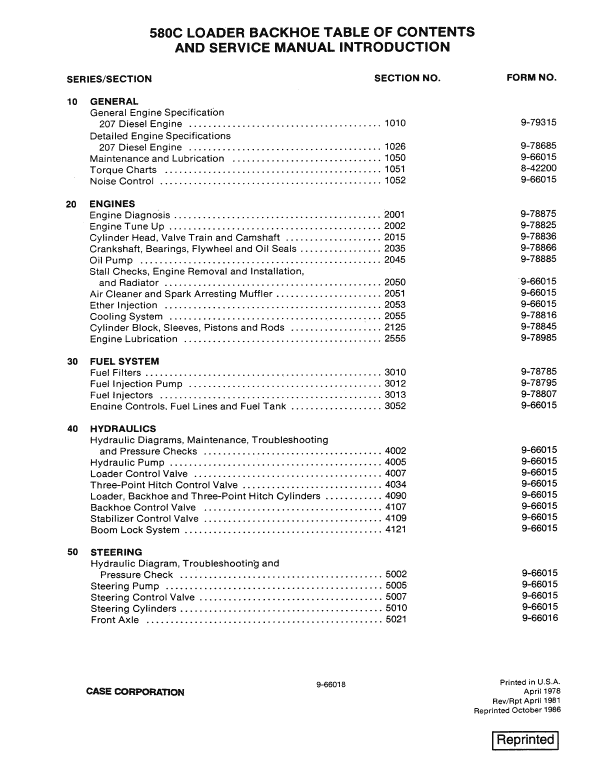

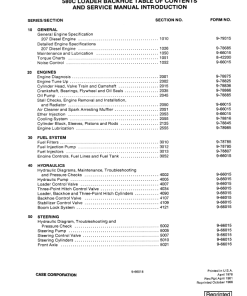

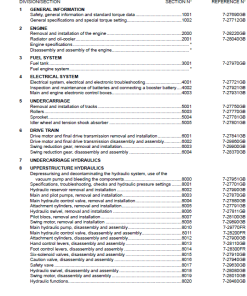

Table of Contents

- General

- Engines

- Fuel System

- Hydraulics

- Steering

- Power Train

- Brakes

- Electrical

- Mounted Equipment

Manual Extract: Radiator Removal and Installation

- Remove the grille and drain the radiator completely.

- Take off the lower guard or cover plate if a counterweight is equipped.

- Disconnect the oil cooler lines at hose connections. Make sure to plug the oil cooler to prevent oil loss and maintain cleanliness. Also, plug cooling lines to prevent dirt entry.

- Unscrew and remove the bottom radiator support to frame nuts, washers, and bolts.

- Detach both the upper and lower radiator hoses.

- If applicable, remove the air cleaner intake tube.

- Take out the rear mounting bolt on each side of the shroud.

- Using a chain hoist, move the shroud forward to clear the fan blades, lift the shroud from the machine, and set it on blocks.

- Remove the nuts and lock washers from the studs on the bottom of the radiator.

- Take off the radiator mounting strap to shroud nuts, washers, and bolts on each side before removing the radiator from the shroud.

- If the radiator is going to a repair shop, use a sharp putty knife to remove the foam rubber baffles from the radiator. Also, ensure the oil cooler is detached.

- Reinstall the radiator by reversing the removal procedure.

- Apply a good grade of contact cement to attach the baffles to the radiator according to the manufacturer’s instructions. Do not omit the baffles.

- If permanent antifreeze is not used in the cooling system, ensure the addition of a rust inhibitor and water pump lubricant. Also, include an anti-cavitation inhibitor using Part Number 331-508.

Key Features

- Step-by-step removal and installation instructions for radiators.

- Emphasizes cleanliness and machine care during the process.

- Details on handling oil coolers and cooling lines.

- Includes advice on safe shroud removal and handling with a chain hoist.

Benefits

- Promotes machine longevity and reliability.

- Ensures safety and efficiency in radiator maintenance.

- Reduces potential damage to components during the maintenance process.

Usage Recommendations

- Follow each step precisely to avoid errors during removal or installation.

- Use recommended tools and equipment like a chain hoist for safety.

- Regularly check for any leaks or discrepancies after installation is complete.

- Ensure the cooling system is treated with appropriate inhibitors if not using permanent antifreeze.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.00

$33.00

$33.50

$33.00

$34.50

$34.00

Reviews

There are no reviews yet.