Maintenance and Troubleshooting Guide

Table of Contents

- General

- Engines

- Fuel System

- Hydraulics

- Steering

- Power Train

- Brakes

- Electrical System

- Mounted Equipment

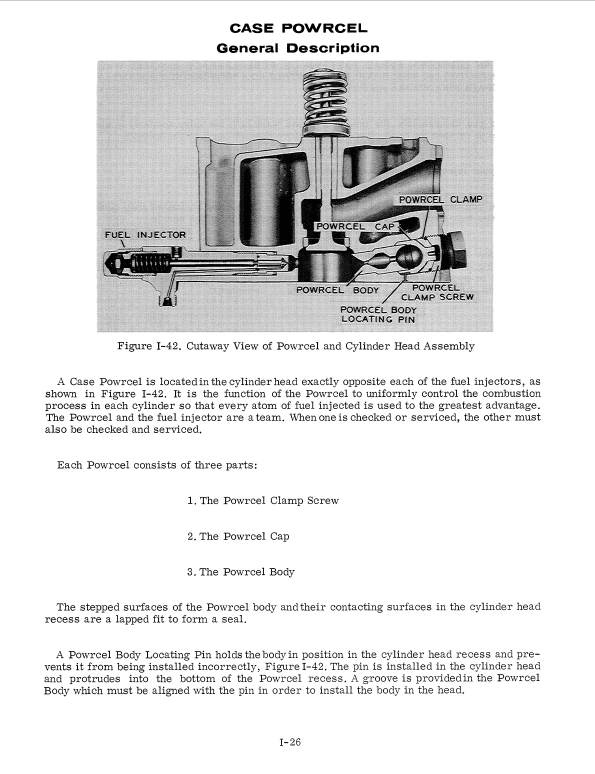

Manual Extract: Diagnosing Injector Issues

If your engine is experiencing a misfire on one cylinder, it may be due to a malfunctioning injector. It’s important to check injectors at idling speed, as faults are more apparent then.

To identify a faulty injector, use a 3/4 inch open-end wrench to loosen the high-pressure fuel line fitting on each injector, one at a time, while the engine is running. This process allows fuel to escape from the line, deactivating the injector and enabling you to observe the changes in engine performance.

Recommended Diagnostic Method

- Ensure the engine is warmed to its operating temperature.

- Use an accurate tachometer to check both engine idling speed (throttle in idle) and no-load full-governed speed (throttle full open) as per the instructions on Page 1-32.

- Deactivate each injector individually and record changes in both engine speeds. The injector that causes the least change is likely to be the faulty one.

Important Note

Whenever you suspect an injector fault, also check the opposite Powrcel by removing and inspecting it. A blocked or damaged Powrcel can impair engine performance similarly to a faulty injector. Moreover, a faulty injector can contaminate the opposite Powrcel.

Additional Recommendations

- Always use the correct tools to avoid damaging injector components during inspection.

- Regularly maintain injectors and Powrcels to ensure peak engine performance.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.