Case 7210, 7220, 7240, 7250 Pro Series Tractor Service Manual

$35.00

Enhance your tractor’s longevity with the comprehensive New Holland Tractor Service Manual. This manual includes detailed guidance for models 7210, 7220, 7240, and 7250 Pro.

Brand: New Holland

Type: Tractor

Manual: Service Manual

Specifications:

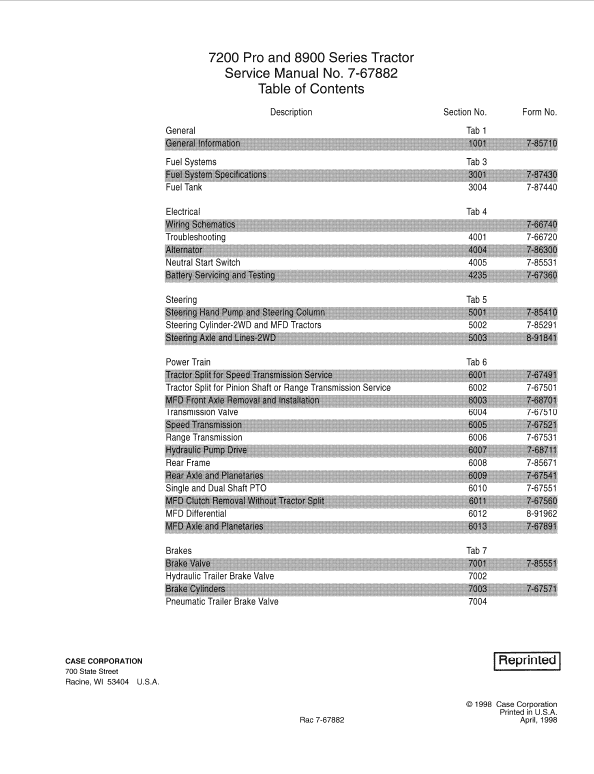

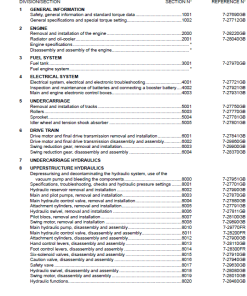

Service Manual Table of Contents

Product Overview

This comprehensive service manual provides detailed information and guidance for maintaining and troubleshooting various systems of your machinery. It is an indispensable resource for ensuring the optimal performance and longevity of your equipment.

Key Features

- General Overview

- Engine Maintenance

- Fuel System Specifications

- Electrical System Details

- Steering Mechanisms

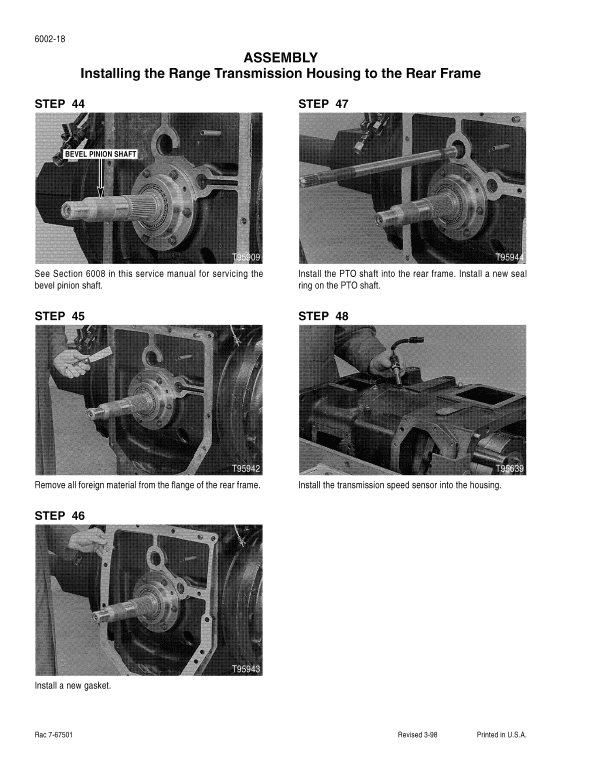

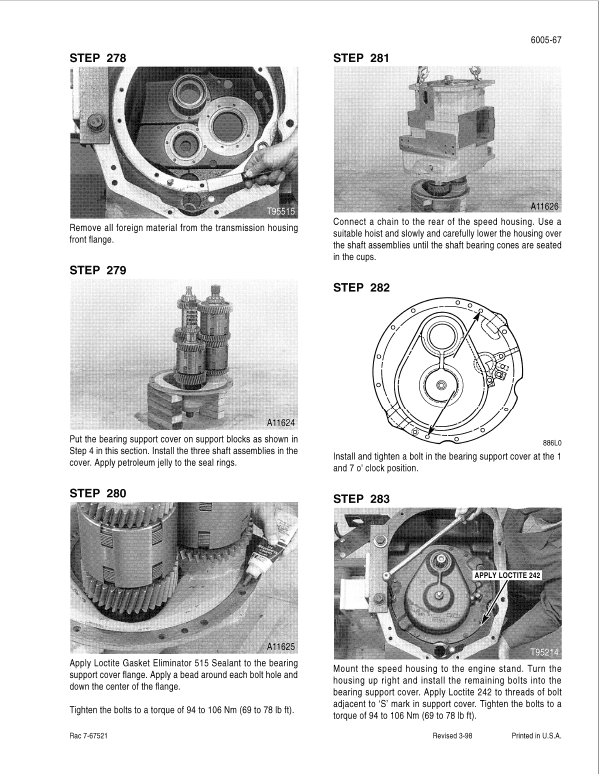

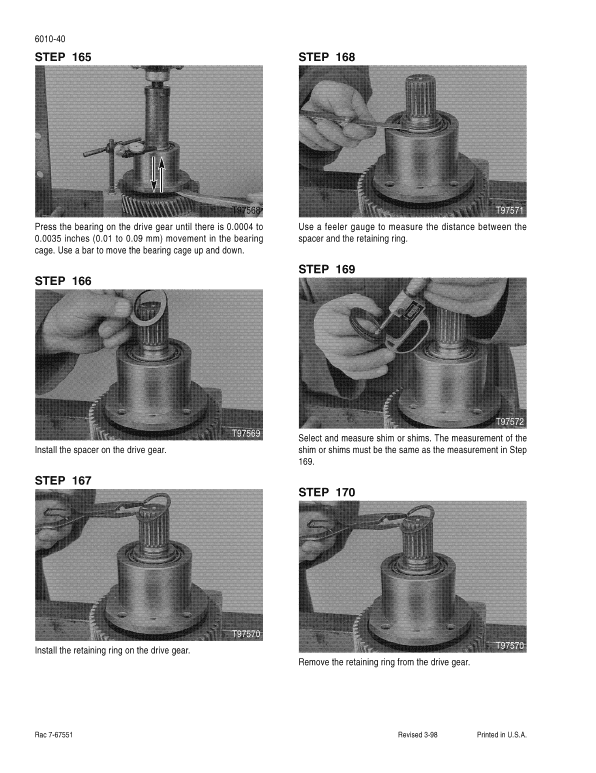

- Power Train Guidance

- Brake System Insights

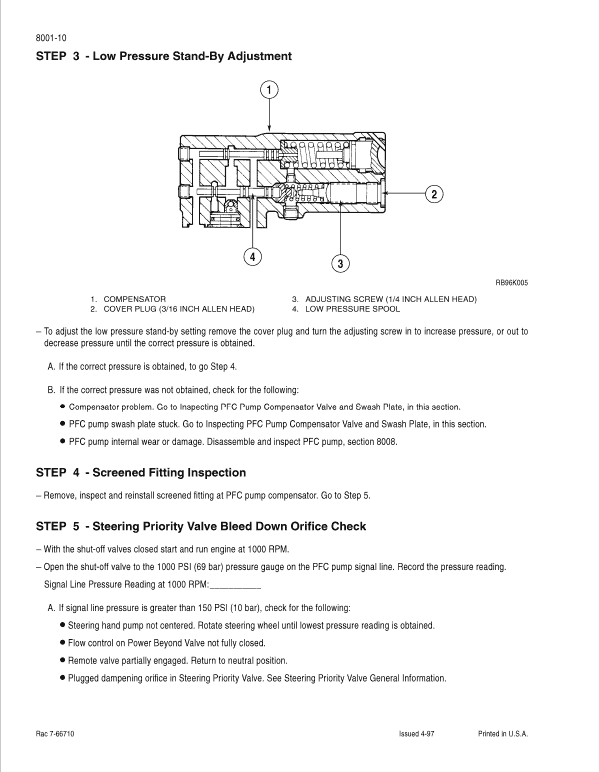

- Hydraulic System Information

- Chassis Configuration

Manual Extract: Minimum System Pressure Check

To perform a minimum system pressure check, follow these essential steps:

- Firstly, connect the signal line tube to the compensator.

- Ensure that the minimum system pressure is within the specified range of 400 to 650 PSI (27.6 to 44.8 bar), or 400 to 750 PSI (27.6 to 51.7 bar) for tractors with hydraulic trailer brakes.

Actions Based on Pressure Readings:

- If within specification: Proceed with the PFC Pump High Pressure Stand-By Test and Adjustment Procedure.

- If above specification: Investigate potential issues such as:

- Power beyond valve flow control not fully closed.

- Partially blocked dampening orifice in the steering priority valve.

- Remote valve partially engaged.

- Steering hand pump not centered.

- If below specification: Conduct the General Hydraulic System Test to examine:

- Missing dampening orifice in the steering priority valve.

- Blocked dynamic orifice.

- Signal check leakage.

Benefits

- Improved equipment maintenance efficiency by providing clear diagnostics.

- Enhanced troubleshooting accuracy with detailed guidance.

- Extended lifespan of machinery through proper care and adjustments.

Usage Recommendations

- Regularly consult this manual to ensure adherence to maintenance schedules.

- Use this guide as a reference during routine check-ups and repairs.

- Share important sections with your maintenance team for effective team collaboration and understanding.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$32.00

$34.00

$35.00

$34.00

$33.00

Reviews

There are no reviews yet.