Comprehensive Inspection Manual for Pistons, Rings, Sleeves, and Connecting Rods

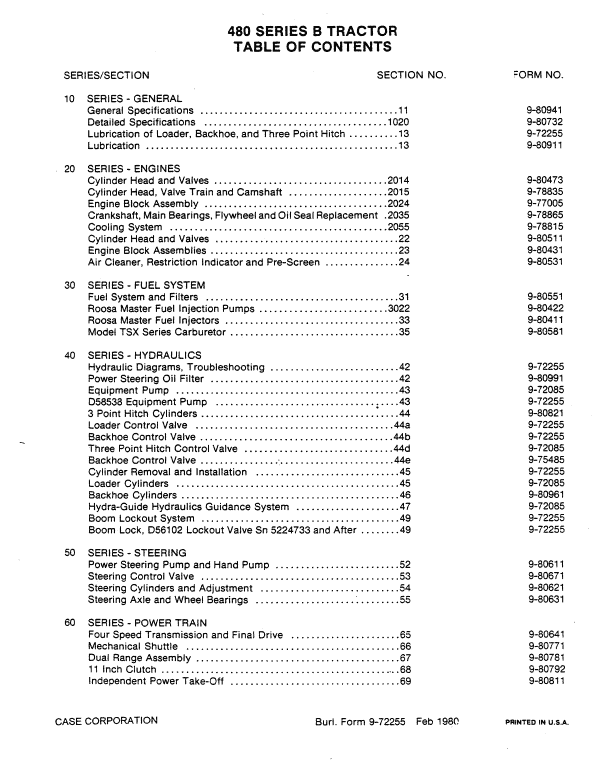

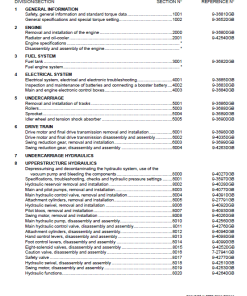

Table of Contents

- General

- Engine

- Fuel System

- Hydraulics

- Steering

- Power Train

- Brakes

- Electrical

- Mounted Equipment

- How it Works

Product Overview

The manual provides detailed instructions for inspecting and maintaining essential engine components like pistons, rings, sleeves, and connecting rods. Following these guidelines ensures the longevity and optimal performance of your equipment.

Key Features

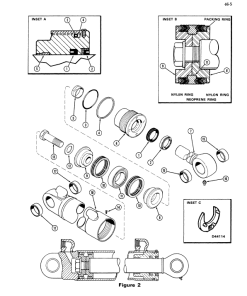

- Detailed Cleaning: Guidance on cleaning all parts to remove nicks, burrs, scratches, grooves, and excessive wear.

- Comprehensive Inspection: Steps to inspect connecting rods and caps for cracks, twists, bowed, or bent conditions.

- Carbon Removal Techniques: Advice on safely removing carbon deposits without damaging the piston surface.

- Piston Pin Evaluation: Methods to check for cracks, score marks, or pitting on piston pins.

- Precision Measurements: Precise tolerance measurements for pin bores and bushings.

- Oil Hole Maintenance: Instructions on cleaning oil holes and replacing block pipe plugs.

Benefits

- Enhances equipment performance and reliability through regular maintenance.

- Reduces downtime by identifying and addressing wear or damage early.

- Promotes longevity of engine components through proper inspection and cleaning.

Usage Recommendations

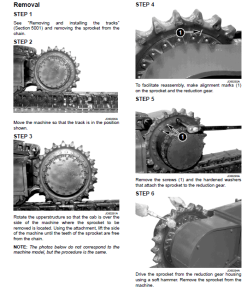

- Ensure thorough cleaning and inspection of all related parts during maintenance.

- Replace components showing wear or damage promptly to prevent further issues.

- Utilize proper tools, such as a ring groove cleaning tool, to avoid surface damage.

- Apply Permatex #2 to pipe plug threads before installation for secure fitting.

For further information or troubleshooting tips, please consult the manufacturer’s official manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.50

$33.00

$33.00

$34.00

Reviews

There are no reviews yet.