Product Manual: Valve Drive and Gears Check

Product Overview

This manual section provides detailed instructions on how to inspect and maintain the valve drive and gears in an engine system. The guide focuses on regular checks to ensure optimal performance and prevent potential damage.

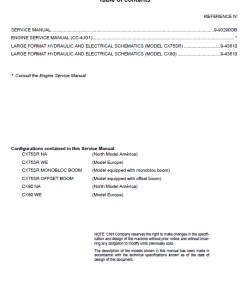

Table of Contents

- Content Overview

- Introduction

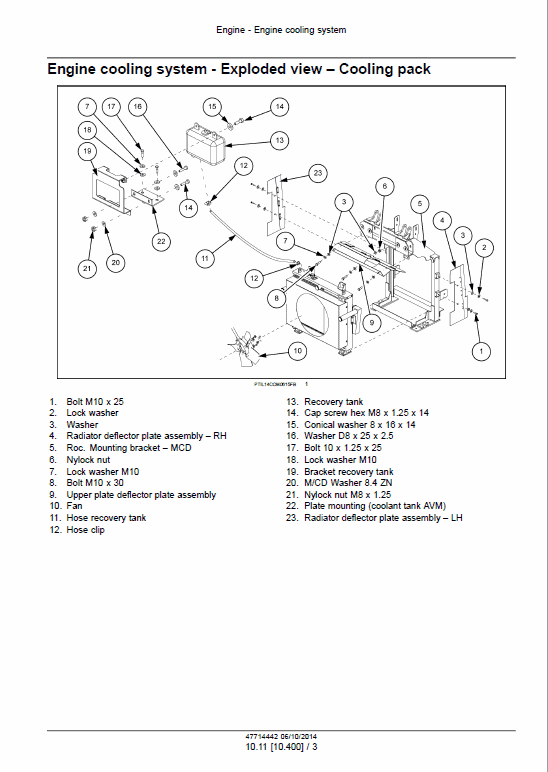

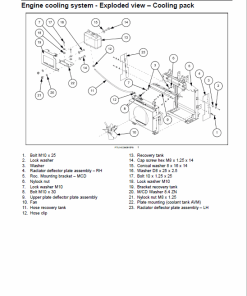

- Engine Components

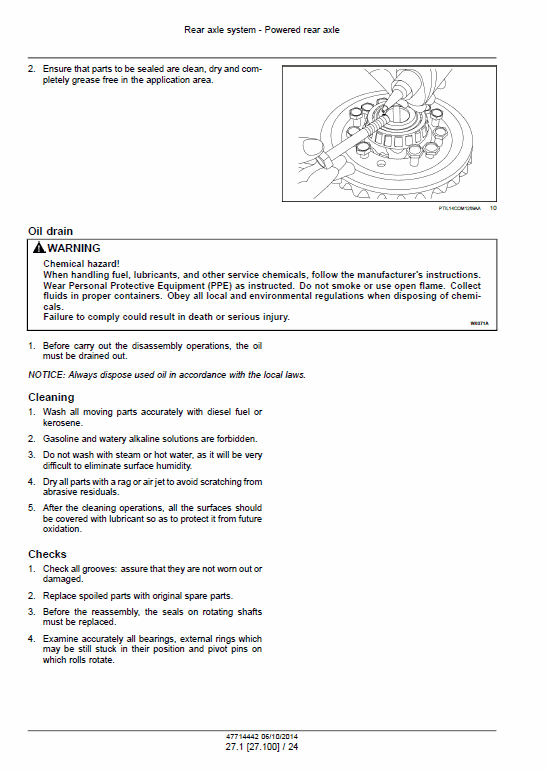

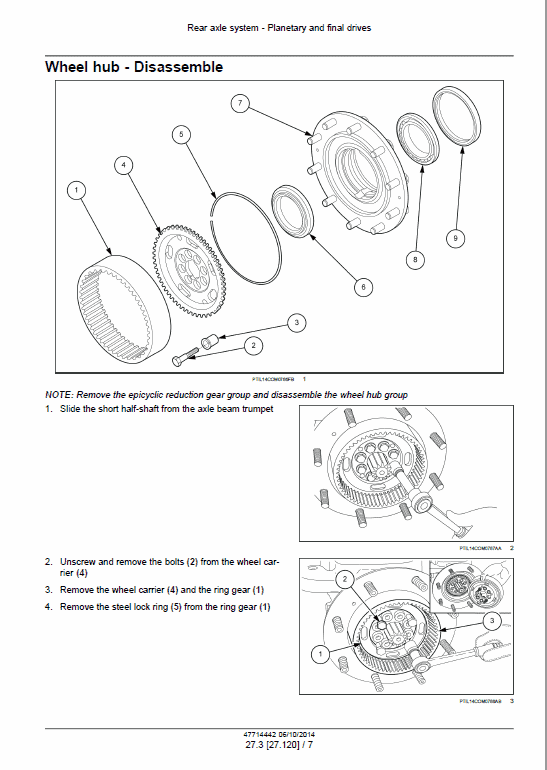

- Rear Axle System

- Hydrostatic Drive

- Brakes and Controls

- Hydraulic System

- Frames and Ballasting

- Steering

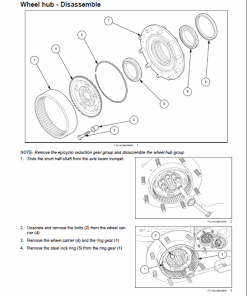

- Wheels

- Electrical System

- Platform, Cab, Bodywork, and Decals

- Special Tool Index

Key Features

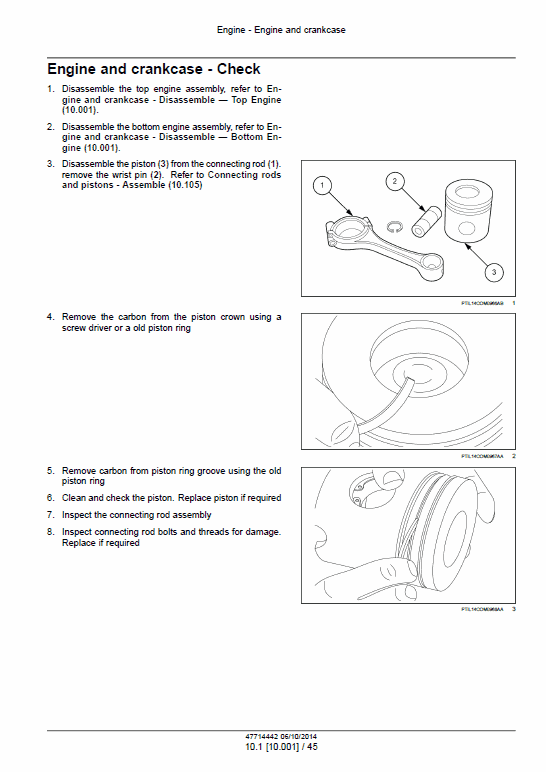

- Comprehensive Disassembly Instructions: Step-by-step guide on disassembling engine parts for a thorough inspection.

- Detailed Inspection Steps: Detailed instructions on checking intermediate gear and related components for damage.

- Measurement Guidance: Instructions on measuring critical dimensions using precise tools to ensure parts are within specified limits.

Benefits

- Preventative Maintenance: Regular checks help in identifying potential issues before they lead to significant engine damage.

- Improved Engine Longevity: Ensuring components are in good condition can extend the lifespan of your engine.

- Enhanced Performance: Proper maintenance leads to smoother engine operation and performance.

Usage Recommendations

- Ensure the engine is completely disassembled following the disassembly instructions before conducting checks.

- Inspect the intermediate gear for tooth damage, and replace it along with the bush bearing if any damage is detected.

- Measure the internal diameter of the gear bush in two perpendicular planes. Replace the bush if it exceeds recommended limits.

- Use a micrometer to check the gear support journal diameter for wear, and replace if necessary.

- Replace washers and fasteners if any damage is present.

For detailed procedures on each step, please refer to appropriate sections in the manual under the headings for disassembly of both top and bottom engine components.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.00

$34.00

$34.00

$33.00

Reviews

There are no reviews yet.