Case 2550 Crawler Dozer Service Manual

$32.00

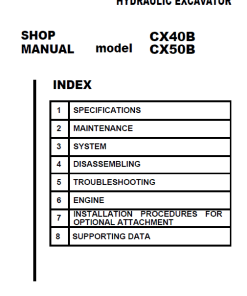

Manual Included: Comprehensive service manual comprising 316 pages.

Specifications

- Brand: New Holland

- Model: 2550

- Type: Dozer

- Manual: Service Manual

- Publication Number: 84414739B

- Language: English

- Format: PDF

Access detailed guidelines and specifications to efficiently operate and maintain your New Holland 2550 Dozer.

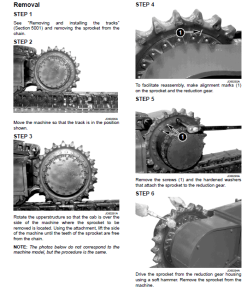

Undercarriage Guide

Product Overview

The undercarriage system is a crucial component designed for enhanced stability and maneuverability in heavy machinery. Crafted with rigorously tested materials, this undercarriage system provides superior performance in various terrain conditions.

Key Features

- Durable Track Frames: Made from steel plate with a boxed structure, ensuring robust performance. The frames pivot on the rear sprocket shaft and offer a total oscillation of 410 mm.

- Track Chains: Features a split-type with sealed and lubricated (SALT) chains, included as a standard for enhanced longevity.

- Track Tension Adjuster: Utilizes a spring-loaded mechanism with a hydraulic adjuster for precise tension control.

- Track Rollers: Includes seven permanently lubricated bottom rollers, five with single flanges, and two with double flanges.

- Track Carrier Rollers and Idler Wheels: Permanently lubricated for minimum maintenance requirements.

- Sprockets: Equipped with nine replaceable bolted toothed segments, offering an anti-packing tooth profile for efficiency.

- Track Chain Design: Composed of forty-one shoes that ensure optimal traction and load distribution.

Benefits

- Durability: Built to withstand harsh environmental conditions, minimizing downtime and repair costs.

- Maintenance Efficiency: Designed with replaceable components to streamline maintenance procedures.

- Precision Control: The hydraulic track tensioner ensures that adjustments can be made quickly and accurately, improving overall operational control.

Usage Recommendations

- Ideal for heavy-duty applications that require reliable performance across diverse terrains.

- Regularly inspect the track components to ensure optimal lubrication and replace any worn parts to maintain performance.

- Utilize manufacturer-specified guidelines for adjustments and replacements to preserve the integrity of the system.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.00

$32.00

$32.00

Reviews

There are no reviews yet.