Comprehensive Maintenance Guide for Machinery

Product Overview

This manual provides a detailed guide on maintaining and operating various components of machinery. Developed with precision and safety in mind, this guide is an essential tool for technicians and engineers responsible for machinery upkeep.

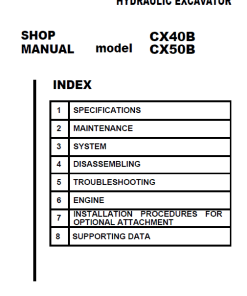

Table of Contents

- Content Overview

- Introduction

- Engine

- Transmission

- Front Axle

- Rear Axle

- Hydraulic System

- Brakes and Controls

- Steering

- Wheels

- Cab Climate Control

- Electrical System

- Front Loader and Bucket

- Platform, Cab, Bodywork, and Decals

- Special Tool Index

Manual Extract: Basic Instructions – Shop and Assembly

Shimming Procedure

For optimal adjustment, select and measure each shim individually using a micrometer. Sum the values for accuracy. Avoid measuring the entire shim pack due to potential inaccuracies, and do not rely solely on the rated values printed on the shims.

Rotating Shaft Seals Installation

Follow these steps for proper installation of rotating shaft seals:

- Pre-soaking: Immerse the seal in the target oil for at least 30 minutes prior to assembly.

- Surface Preparation: Clean the shaft thoroughly, ensuring the working surface is undamaged.

- Seal Positioning: Orient the sealing lip towards the fluid being sealed.

- Hydrodynamic Lips: Consider shaft rotation direction to effectively channel fluid inward.

- Lubrication: Apply a light oil-based lubricant to the sealing lip; fill the gap between double lip seals with grease.

- Seal Installation: Carefully press the seal into position with a flat punch or seal installation tool, avoiding hammer impacts.

- Alignment: Ensure the seal is perpendicular to its seat during insertion, and confirm contact with the thrust element as necessary.

- Damage Prevention: Use a protective guard to safeguard the sealing lip during installation.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.00

$34.00

$35.00

$34.00

$34.00

$34.00

Reviews

There are no reviews yet.