Hydraulic Pump Efficiency Test Manual

Table of Contents

- Introduction

- Hydraulic

- Pneumatic

- Electrical

- Electronic

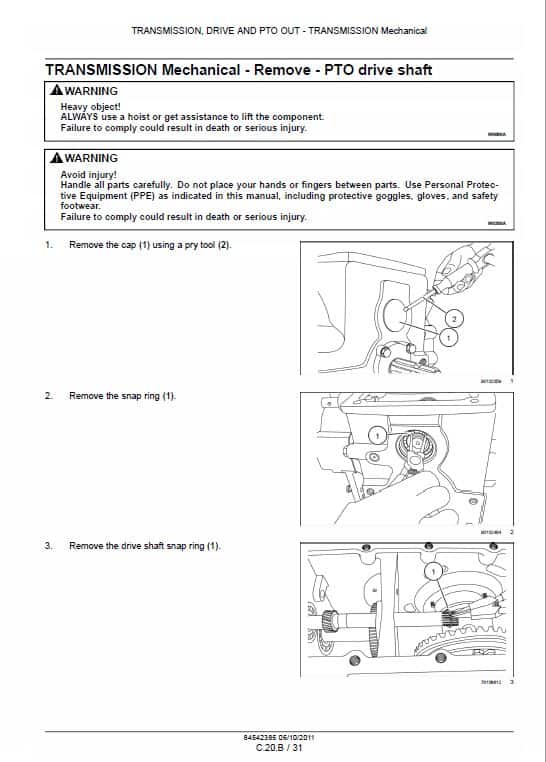

- Transmission

- Drive and Power Takeoff

- Axles

- Brakes and Steering

- Frame and Cab

- Hitch and Working Tool

Overview: Pump Efficiency Test

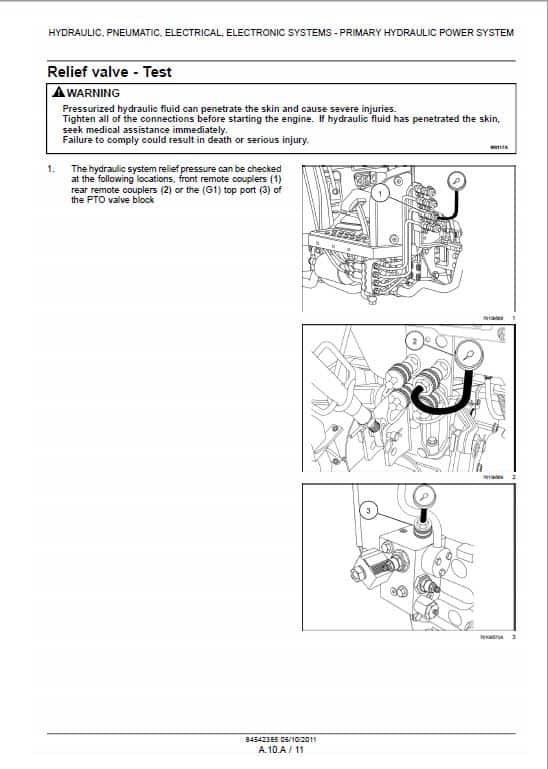

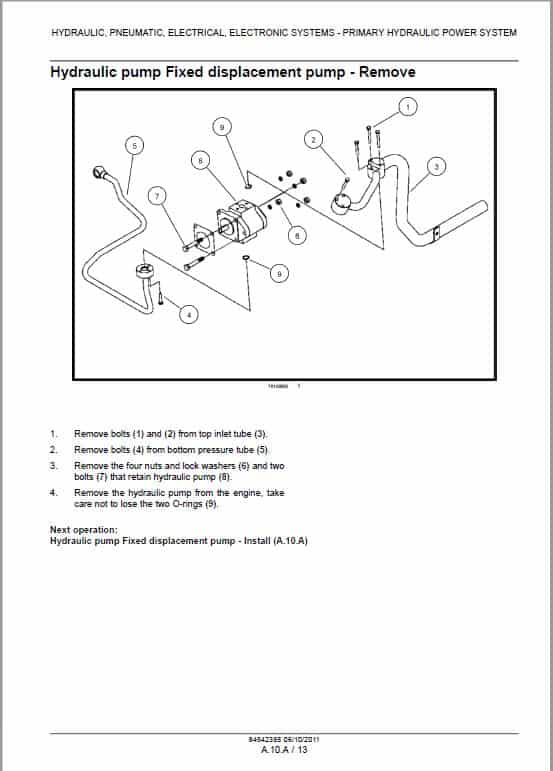

The pump efficiency test is designed to evaluate the hydraulic pump’s flow output under load conditions. It helps identify whether the pump is excessively worn or damaged. Before conducting this test, ensure the inlet restriction test has been completed. You will need a hydraulic flow meter for the pump efficiency test.

Key Features

- Compatible with mid-mount two spool valve or optional rear remote valve female quick couplers.

- Flow meter necessary for accurate measurement.

Benefits

- Determines hydraulic pump condition.

- Helps in timely pump replacement to avoid further damage.

Usage Recommendations

- Begin by starting the tractor engine and operating the hydraulic system to reach normal operating temperatures.

- Securely connect flow meter hoses to the valve outlet connectors, ensuring they are placed within the same valve circuit: (A) output and (B) return.

-

Operate the tractor at the specified RPM for each model:

- Farmall 30 B: 2600 RPM

- Farmall 35 B: 2700 RPM

- Check the flow meter reading for a no-load condition, aiming for approximately:

- 31.2 l/min (8.2 US gpm) – Farmall 30 B

- 32.4 l/min (8.6 US gpm) – Farmall 35 B

- Adjust the flow restrictor valve on the flow meter until the pressure reaches between 13100 – 13790 kPa (1900 – 2000 psi).

- Observe the flow meter reading again. It should reflect 80% of the no-load flow rating:

- 25 l/min (6.6 US gpm) – Farmall 30 B

- 26 l/min (6.9 US gpm) – Farmall 35 B

- If the hydraulic pump output is below expected values, consider replacing the pump to maintain optimal performance.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.00

$33.00

$34.00

$35.00

$33.00

$33.50

Reviews

There are no reviews yet.