Komatsu Service and Repair Manual

Product Overview

The Komatsu Service and Repair Manual is an essential guide for ensuring the safe operation and maintenance of your machinery. It provides detailed instructions and techniques, formulated by Komatsu experts, for effective and secure service and repair procedures. These procedures often require specialized tools designed specifically for Komatsu equipment.

Table of Contents

- Index and Foreword

- Specification

- Structure, Function, and Maintenance Standards

- Standard Value Table

- Testing and Adjusting

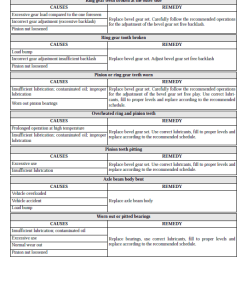

- Troubleshooting

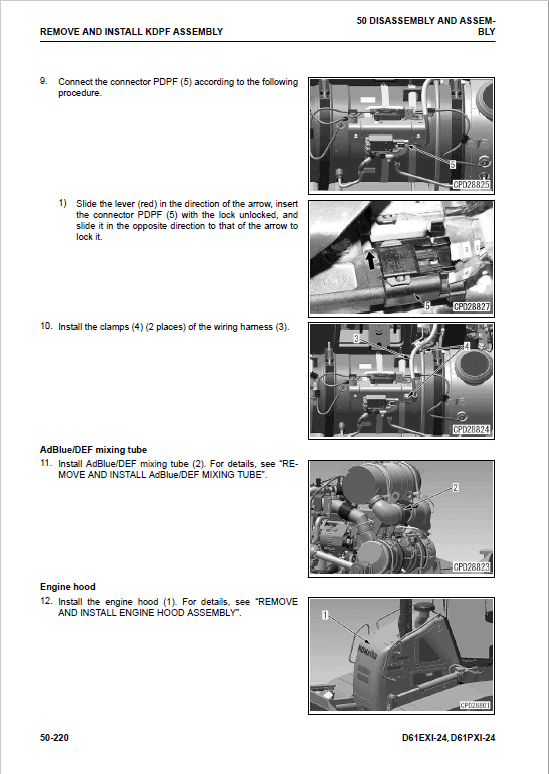

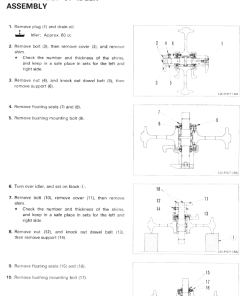

- Disassembly and Assembly

- Maintenance Standard

- Appendix

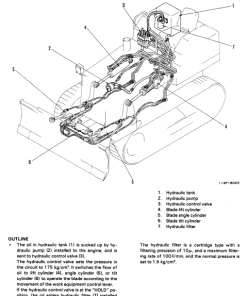

- Diagrams and Drawings

Manual Extract: Loaded Diagnostics Operation to Clear Failure Code

To confirm completion of a repair and clear the failure code, please follow the procedure below:

- Turn the starting switch from the OFF position to the ON position.

- Start the engine and allow it to idle at a low speed for 15 minutes.

If the failure code clears, the repair is complete. If not, proceed as follows:

Notice: If the failure code persists after steps 1 and 2, appropriate temperature conditions are also necessary. Steps 4 and 5 are required to meet these conditions.

- KDOC outlet temperature should be 200 u00b0C or above.

- KDPF outlet temperature should be 200 u00b0C or above.

- Use the monitoring function to display the KDOC and KDPF outlet temperatures.

- Engage the blade raise relief continuously for 15 minutes with the fuel control dial set to MAX (high idle) position.

- If neither the KDOC nor KDPF outlet temperatures reach 200 u00b0C, perform the “Loaded Diagnostics Operation To Clear Failure Code” [CA1883].

- Once the failure code is cleared, the repair process is concluded.

For additional resources and tools, please refer to the specific sections within this manual, or visit Komatsu’s official website for further support and information.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.