Komatsu Equipment Maintenance and Service Manual

Product Overview

This comprehensive manual is designed for Komatsu equipment owners and service professionals. It provides detailed guidelines for safe and effective machine operation, maintenance, and repair. The techniques outlined in this manual adhere to the high standards set by Komatsu, ensuring optimal performance and safety. Familiarity with these procedures will enable users to perform maintenance tasks confidently and efficiently.

Table of Contents

- Index and Foreword

- Specification

- Structure, Function, and Maintenance Standard

- Standard Value Table

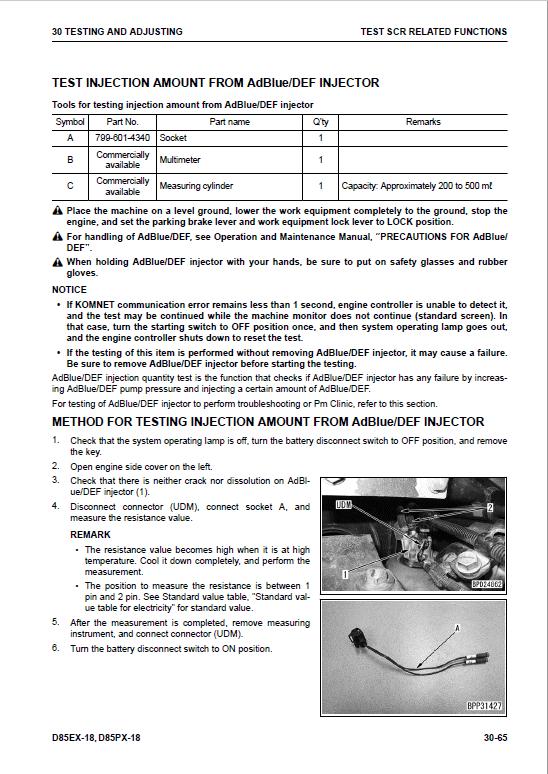

- Testing and Adjusting

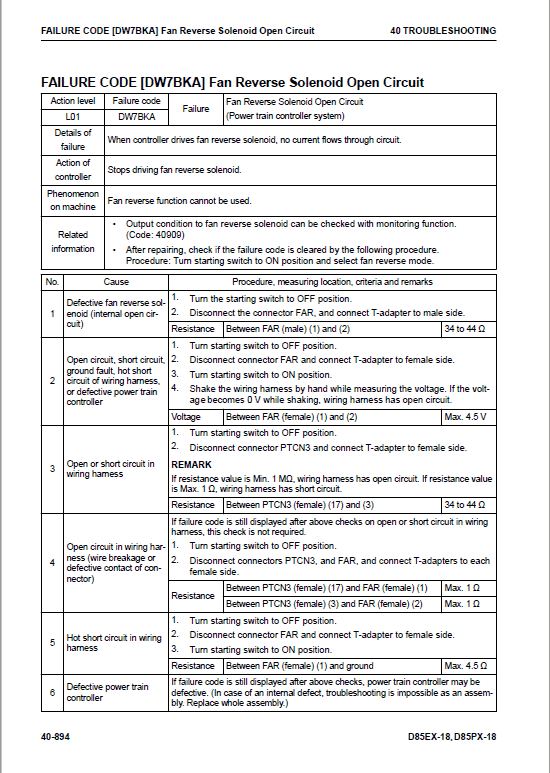

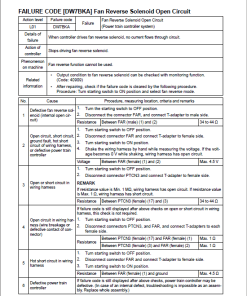

- Troubleshooting

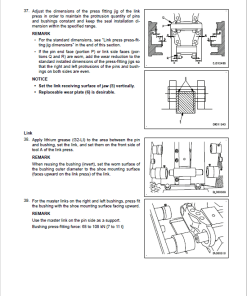

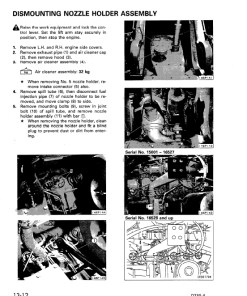

- Disassembly and Assembly

- Maintenance Standard

- Appendix

- Circuit Diagrams

Key Features

- Detailed Instructions: Clear and precise guidelines for all maintenance and repair tasks.

- High Safety Standards: Techniques based on Komatsuu2019s safety recommendations.

- Specialized Tools: Information on tools specifically designed by Komatsu for particular procedures.

Benefits

- Enhanced Safety: Perform repairs and maintenance with confidence, reducing the risk of injury and equipment damage.

- Prolonged Equipment Life: Proper maintenance increases the durability and effectiveness of your Komatsu machinery.

- Efficient Troubleshooting: Quickly identify and resolve machine issues with step-by-step troubleshooting sections.

Usage Recommendations

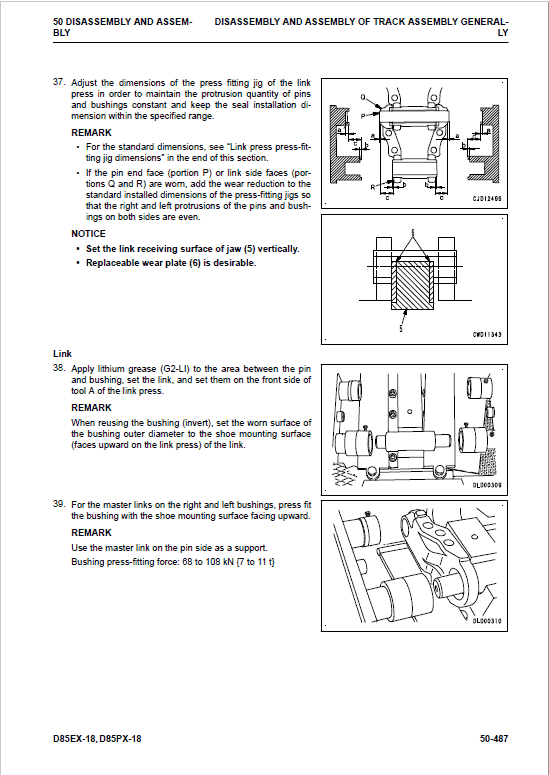

- Shoe Bolt Handling: If loosening a shoe bolt does not reduce its rotational torque to zero, loosen other bolts for smooth removal. Avoid forcing the bolt if torque remains; this could cause deformation.

- Master Link Care: Exercise caution to avoid damaging the master link when moving the shoe assembly.

- Shoe Nut Removal: During gas cutting, maintain seal temperatures below 80u00b0C and prevent flame-cutting droplets from entering link clearances to avoid seal damage.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.50

$34.00

$33.50

$33.00

$34.00

Reviews

There are no reviews yet.