Hyundai R25Z-9A Crawler Excavator Service Repair Manual

$34.00

Explore detailed guidance for the Hyundai R25Z-9A Crawler Excavator with comprehensive manuals available in PDF format.

- Service Repair Manual: 411 pages of in-depth maintenance and repair instructions.

- Operators Manual: 179 pages of essential operating guidelines.

Language: English

Hyundai R25Z-9A Crawler Excavator Service Repair Manual

Product Overview

The Hyundai R25Z-9A Crawler Excavator Service Repair Manual is an essential resource designed to aid professionals in conducting high-quality repairs. It offers comprehensive guidance by providing detailed information on the product’s functionality and the correct procedures for performing repairs and making informed judgments. This manual is primarily intended for use in service workshops, ensuring technicians have the knowledge to effectively maintain and repair the R25Z-9A model.

Crawler Excavator Model: R25Z-9A

Language: English

Format: PDF

Key Features

- Service Repair Manual – 411 Pages

- Operators Manual – 179 Pages

- Comprehensive sections covering safety, specifications, hydraulic and electrical systems, and more

- Detailed troubleshooting guides for resolving common mechanical and electrical issues

Benefits

- Enhances the quality of service by providing an accurate understanding of the excavator’s components and systems

- Improves technician efficiency by offering clear, step-by-step instructions

- Reduces downtime and increases equipment reliability through proper maintenance and repair practices

Usage Recommendations

- Utilize the manual in professional service workshops to ensure repairs are conducted by trained technicians

- Familiarize yourself with the safety hints and specifications before commencing any repair work

- Refer to the troubleshooting section for assistance in diagnosing and resolving issues efficiently

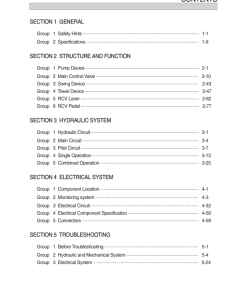

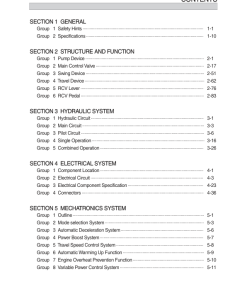

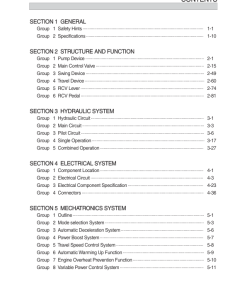

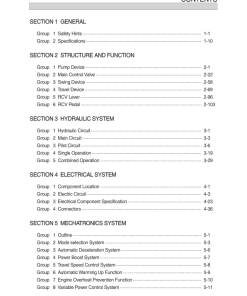

Table of Contents

- FOREWORD

- GENERAL

- 1. Safety hints

- 2. Specifications

- STRUCTURE AND FUNCTION

- 1. Pump device

- 2. Main control valve

- 3. Swing device

- 4. Travel device

- 5. RCV Lever

- 6. RCV Pedal

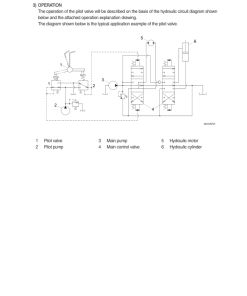

- HYDRAULIC SYSTEM

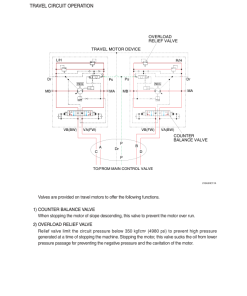

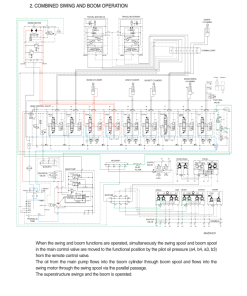

- 1. Hydraulic circuit

- 2. Main circuit

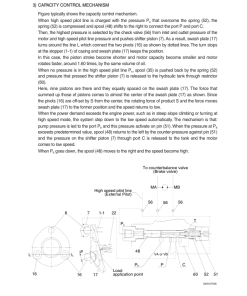

- 3. Pilot circuit

- 4. Single operation

- 5. Combined operation

- ELECTRICAL SYSTEM

- 1. Component location

- 2. Monitoring system

- 3. Electrical circuit

- 4. Electrical component specification

- 5. Connectors

- TROUBLESHOOTING

- 1. Before troubleshooting

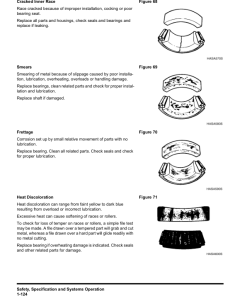

- 2. Hydraulic and mechanical system

- 3. Electrical system

- MAINTENANCE STANDARD

- 1. Operational performance test

- 2. Major components

- 3. Track and work equipment

- DISASSEMBLY AND ASSEMBLY

- 1. Precaution

- 2. Tightening torque

- 3. Pump device

- 4. Main control valve

- 5. Swing device

- 6. Travel device

- 7. RCV lever

- 8. Turning joint

- 9. Boom, arm and bucket cylinder

- 10. Undercarriage

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.