PF6170 Service Documentation

Product Overview

The PF6170 service documentation provides comprehensive information for the maintenance and service of the PF6170 machinery, covering essential components and systems. This guide is intended for service professionals and technicians who need detailed service instructions to ensure the machinery operates efficiently and safely.

Key Features

- General Description

- Features a complete overview of the PF6170 machine structure and components.

- Includes essential specifications and operational standards.

- Service Specifications

- Details on the machine’s standard operating time and tool requirements.

- Information on standard parts and lubrication requirements.

- Guidelines for arrival inspections and maintenance tasks.

- Engine and Fuel Systems

- Includes details on engine specifications, mounting, and equipment.

- Covers the fuel system, including the cooler and miscellaneous components.

- Cooling Systems

- Specifications of fan, shroud, coupling, and pump drive systems.

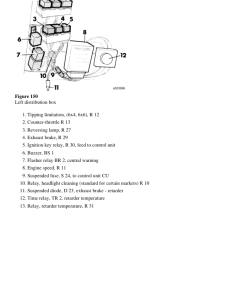

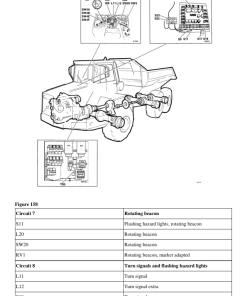

- Electrical Systems

- Information systems, warning systems, and instrument details.

- Battery and energy storage system specifications.

- Transmission and Steering

- Details on clutch and torque converter operations.

- Comprehensive information on steering axle and components.

- Framework and Suspension

- Specifications for frame, springs, damping, and wheel assemblies.

- Cab and External Components

- Descriptions of the engine hood, safety features, and cabin interiors.

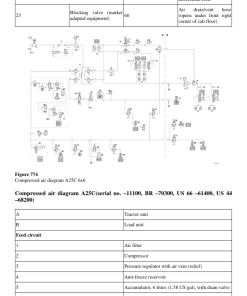

- Hydraulic Systems

- Specifications for digging, handling, and grading equipment.

- Includes servo and working hydraulic systems details.

- Construction Functions

- Functions for road construction, material transport, and control mechanisms.

- Vibration and flow control systems description.

- Environment and Protection

- Systems for fumes extraction and water spraying.

Benefits

- Enhances equipment longevity through regular maintenance and inspections.

- Improves operational efficiency by following detailed service protocols.

- Ensures compliance with safety and operational standards.

Usage Recommendations

- Refer to specific sections to perform routine maintenance and troubleshooting.

- Utilize the correct tools and parts as specified for each component.

- Follow safety guidelines to prevent accidents and equipment damage.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

Articulated Dump Truck

Volvo A25B 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Volvo A25F Articulated Dump Truck Repair Service Manual (SN after 320001 -)

Articulated Dump Truck

Volvo A30F Articulated Dump Truck Repair Service Manual (SN after 320001 -)

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Volvo A25C 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Reviews

There are no reviews yet.