Case 9020B Excavator Service Repair Manual

$36.00

This comprehensive Service Manual is an essential resource for maintaining your Case 9020B Excavator. With 1,093 pages of detailed guidance, this manual is your go-to reference for troubleshooting and repairs.

Service Manual Overview

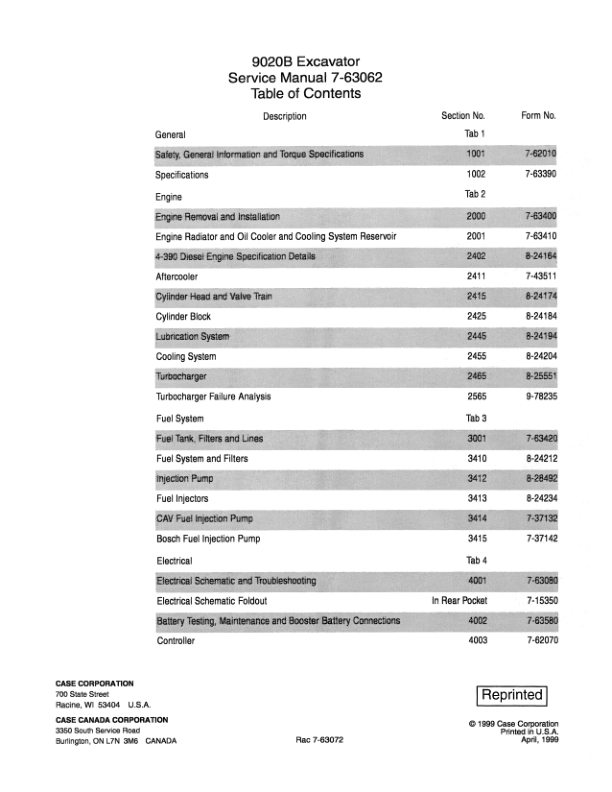

Table of Contents

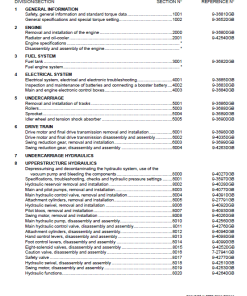

- General

- Engines

- Fuel System

- Electrical

- Steering

- Power Train

- Hydraulics

- Mounted Equipment

- Hydraulic and Electrical Schematics

Manual Extract

Cleaning

Clean all metal parts, except bearings, using a suitable cleaning solvent or through steam cleaning. Avoid using caustic soda for steam cleaning. After cleaning, ensure parts are thoroughly dried and lubricated with oil. Use compressed air to clean oil passages. Bearings should be cleaned with a suitable solvent, fully dried, and oiled.

Inspection

Conduct a thorough inspection of all disassembled parts. Replace parts showing signs of wear or damage. Minor scoring or grooves can be smoothed out using a hone or crocus cloth. Ensure a visual inspection is carried out to identify wear, pitting, or parts that need replacement to prevent early failures.

Bearings

Inspect bearings for smooth operation. Replace any bearings with a loose fit or rough movement. Clean bearings with an appropriate solvent, allowing them to air dry. Important: Do not dry bearings with compressed air.

Needle Bearings

Before pressing needle bearings into a bore, remove any metal protrusions around the bore or its edges. Apply petroleum jelly to both the inner and outer diameters of the bearings before pressing them into place.

Reference: Rae 7-62010

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.