Gehl Z55, Mustang 550Z Compact Excavator Repair Service Manual

$42.00

Explore essential resources for maintaining and repairing your Gehl Z55 or Mustang 550Z excavator. Available in PDF format, these manuals provide comprehensive guidance in English.

Learn more about the Gehl Excavator.

Comprehensive Guide for Hydraulic Equipment Maintenance

Product Overview

This expertly crafted guide provides a thorough overview of essential maintenance procedures for hydraulic equipment. It serves as a vital resource for maintenance professionals, offering detailed insights and instructions to ensure optimal performance and longevity of machinery.

Key Features

- General Cautions for Maintenance Work

- Comprehensive safety precautions and proper handling instructions for hydraulic equipment, seals, and hoses.

- Guidance on correct disassembly and reassembly techniques to prevent accidental damage.

- Technical Data

- Machine specifications including weight distribution, lifting capacities, and working area dimensions.

- Access to hydraulic circuit schematics, wiring diagrams, and recommended lubricants.

- Periodic inspection and servicing schedule guidance.

- Service Standards

- Performance benchmarks for engine, hydraulic systems, and undercarriage components.

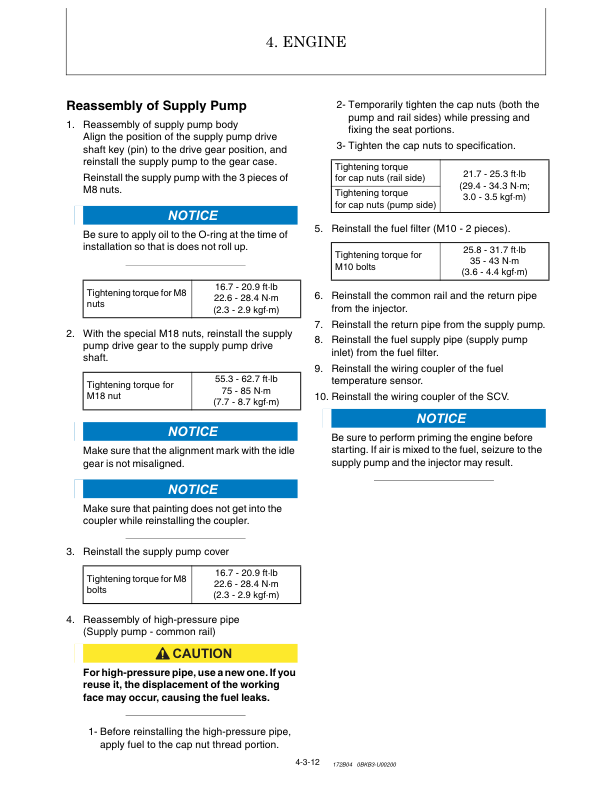

- Tightening torque values and hydraulic fitting pressure adjustments.

- Acceptable and nominal values for critical machine components.

- Engine

- Detailed servicing procedures including valve adjustments and crankshaft maintenance.

- Instructions on maintaining fuel, cooling, and lubrication systems, along with turbocharger care.

- Troubleshooting charts and wiring diagrams for engine components.

- Electric System

- Explanation of electrical component layouts, including LCD monitors and alarm systems.

- Details on electronic control features for start/stop operations, auto deceleration, and eco modes.

- Error code references and troubleshooting techniques.

- Hydraulic System

- Circuit operations for boom, arm, bucket, swing, and blade functions.

- Instructions for handling simultaneous operations and optional systems like quick couplers.

- Maintenance and repair guidelines for pumps, valves, and motors.

- Adjustment and Repair

- Instructions for removal and reinstallation of major components including engine and cabin.

- Repair procedures for hydraulic cylinders, swivel joints, and diesel particulate filters.

- Layouts and diagrams for piping and jigs, aiding in precise adjustments and repairs.

- Troubleshooting

- Diagnostic tools for issues such as bucket release and travel motor thermal shocks.

- Quick reference tables for identifying cause of breakdowns and corrective action steps.

- Guidelines for resolving hydraulic oil fluctuations and quick coupler issues.

Benefits

- Enhances longevity and performance of hydraulic equipment through meticulous maintenance practices.

- Reduces downtime by providing effective troubleshooting methods and solutions.

- Ensures compliance with industry standards through detailed technical data and performance benchmarks.

Usage Recommendations

- Ideal for maintenance professionals seeking comprehensive knowledge in hydraulic system care.

- Suitable for training purposes, providing a holistic view of equipment maintenance operations.

- Can be used as a reference guide for troubleshooting hydraulic machinery issues in real-time.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Loader

$36.00

Articulated Loader

$37.00

$36.00

$33.00

$33.00

Articulated Loader

$36.00

Articulated Loader

$36.00

Reviews

There are no reviews yet.