Doosan DX27Z Excavator Service Manual

$33.00

The Doosan DX27Z Excavator Service Repair Manual is an essential PDF guide containing 586 pages of detailed information. This manual is perfect for anyone needing comprehensive service and repair instructions. It is presented in English and comes with Publication Number K1028288E. The manual applies to excavators with Serial Numbers 5001 and up.

Please follow this link to access the manual: Download the Doosan DX27Z Excavator Service Repair Manual

Doosan DX27Z Excavator Service Manual

Product Overview

The Doosan DX27Z Excavator Service Manual is a comprehensive guide for maintaining and repairing your DX27Z excavator. This manual, comprising 586 pages, provides in-depth information and step-by-step instructions to ensure effective servicing of the equipment. Available in PDF format and written in English, this manual is an essential resource for professionals. Publication No: K1028288E covers excavators with serial numbers 5001 and up.

Key Features

- Format: PDF

- Language: English

- Publication Number: K1028288E

- Compatibility: Serial Number 5001 and Up

- Total Pages: 586

Benefits

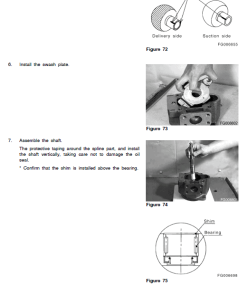

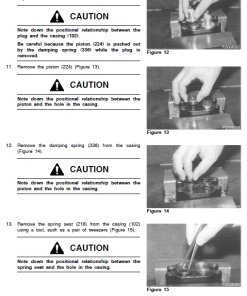

- Detailed service procedures with clear step-by-step guidance.

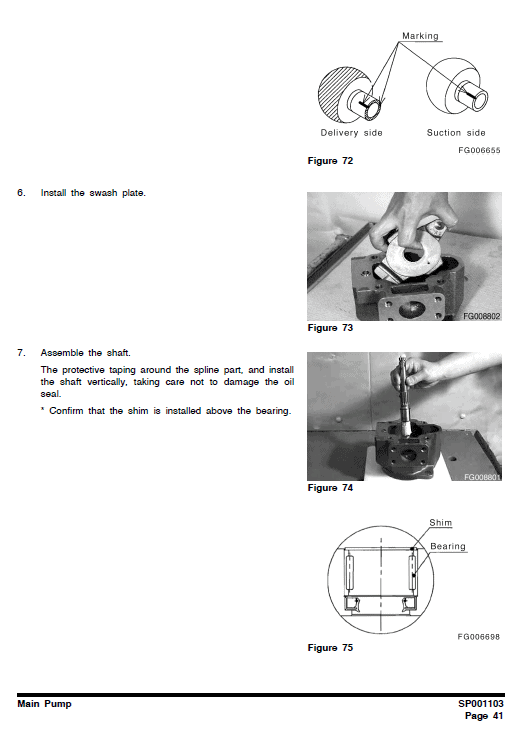

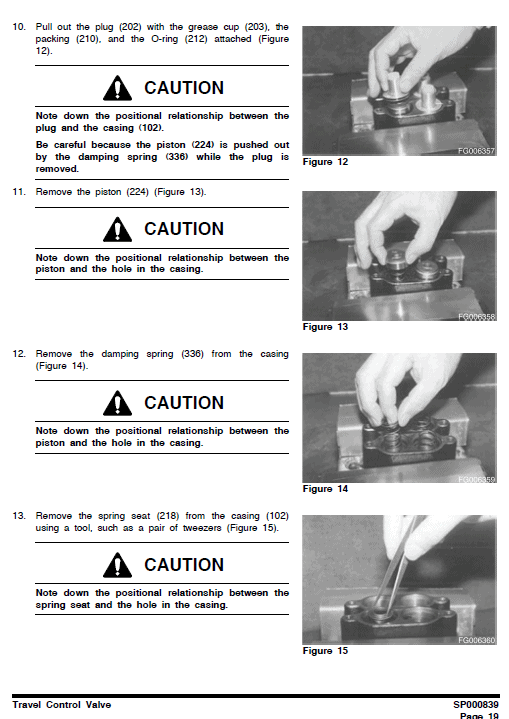

- Visual aids including photographs and drawings for easy identification of components.

- Comprehensive safety information to ensure safe usage of the equipment.

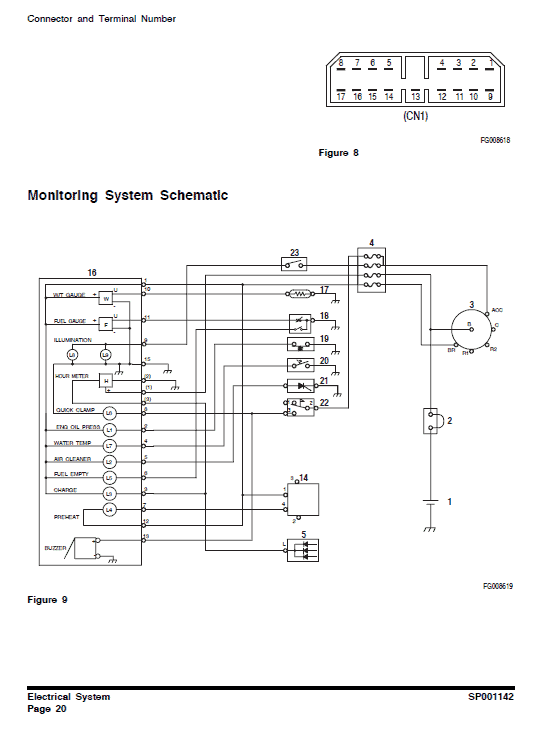

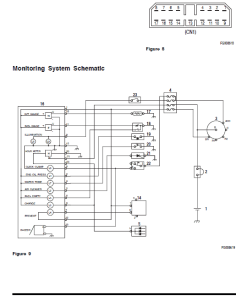

- Schematics for major engine systems to assist with troubleshooting.

Usage Recommendations

- Utilize the table of contents for quick navigation to desired service procedures.

- Review safety sections in both the manual and owneru2019s publication for full hazard awareness.

- Ensure the cleanliness of hydraulic systems to prevent component wear and maintain performance.

- Check and replace filters regularly to maintain hydraulic fluid cleanliness below NAS Class 9.

Manual Content Highlights

The manual includes sections on safety, specifications, maintenance procedures, engine systems, hydraulics, the electrical system, and attachments. Each section provides detailed instructions and schematics, essential for thorough understanding and execution of repair tasks:

- Safety: Track Excavator Safety

- Specifications: DX15/DX18 Specifications

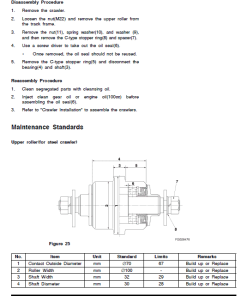

- Maintenance: General Maintenance Procedures, Standard Torques

- Structures: Upper Structure, Lower Structure and Chassis, Track Assembly

- Engine and Drive Train: Engine Details and Systems

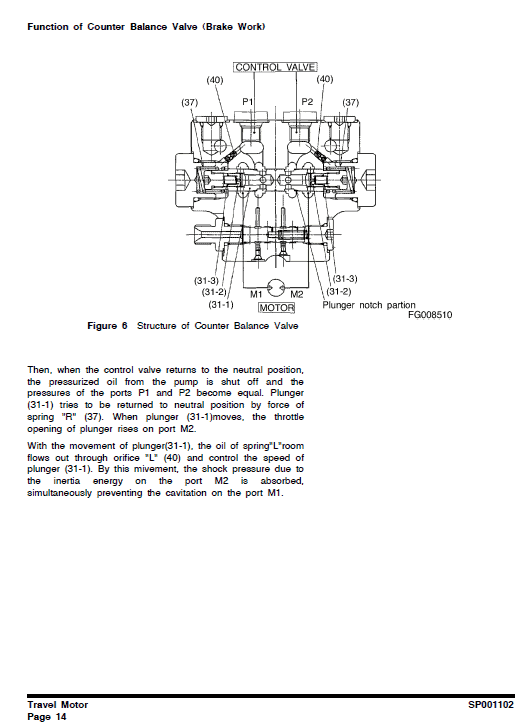

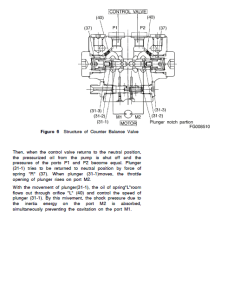

- Hydraulics: Center Joint, Cylinders, Swing Motor, Travel Motor, and related valve systems

- Electrical System: Comprehensive Electrical System Guides

- Attachments: Boom, Arm, and Bucket Couplings

For instance, the maintenance of the piston motor and shuttle valve is critical for optimal performance. Using adequate filters ensures the system’s hydraulic fluid remains clean, robust, and reliable, thus extending the excavator’s service life.

It is advised to monitor the contamination level of hydraulic fluids, keeping them below NAS Class 9. Moreover, filters equipped with visual indicators and relief valves can be installed to preemptively address any clogging issues, ensuring consistent and effective performance.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.