Doosan DX140LC-3 and DX140LC-5 Excavator Service Manual

$35.50

Explore comprehensive service repair manuals for the Doosan DX140LC excavator models.

- Doosan DX140LC-3 Manual: 900 pages

- Doosan DX140LC-5 Manual: 1504 pages

Available in PDF format and written in English.

Publication Numbers: 950106-00388E, 950106-01141E

Serial Numbers: 1001 and up

Doosan DX140LC-3 and DX140LC-5 Excavator Service Manual

Product Overview

Explore the comprehensive service manual for the Doosan DX140LC-3 and DX140LC-5 Excavators. Available in PDF format, this manual is written in English and covers serial numbers 1001 and up. It provides detailed guidance for maintenance and troubleshooting with publication numbers 950106-00388E and 950106-01141E. The DX140LC-3 manual comprises 900 pages, while the DX140LC-5 edition includes 1504 pages.

For more information, visit the Doosan Excavator section.

Key Features

- Extensive coverage with detailed instructions for both models.

- Includes photographs and drawings for clarity and easy navigation.

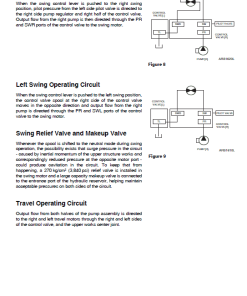

- Schematic diagrams provided for key systems, enhancing troubleshooting and repair processes.

Benefits

- Comprehensive safety guidelines provide a secure maintenance environment.

- Logical structuring facilitates quick access to necessary procedures and components.

- Additional safety precautions and warnings help prevent accidents.

Usage Recommendations

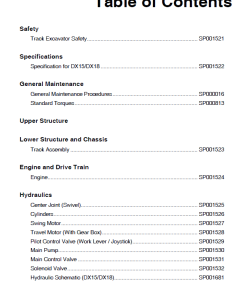

- Refer to the Table of Contents for quick access to required service procedures.

- Observe all safety information diligently before commencing any service task.

- Program injector codes accurately when replacing electronic unit injectors.

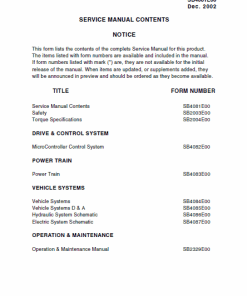

Detailed Table of Contents

- Safety: Track Excavator Maintenance Safety – SP002322

- Specifications: Specifications for DX140LC-3 – SP002509

- General Maintenance: General Maintenance Instructions – SP002454

- Upper Structure:

- Cabin – SP002324

- Counterweight – SP002510

- Fuel Tank – SP002511

- Fuel Transfer Pump (Option) – SP002546

- Swing Bearing – SP002329

- Swing Reduction Gear – SP002526

- Engine and Drivetrain: Engine Coolant Heater (Option) – SP002328, Drive Coupling (Main Pump) – SP002515

- Hydraulics:

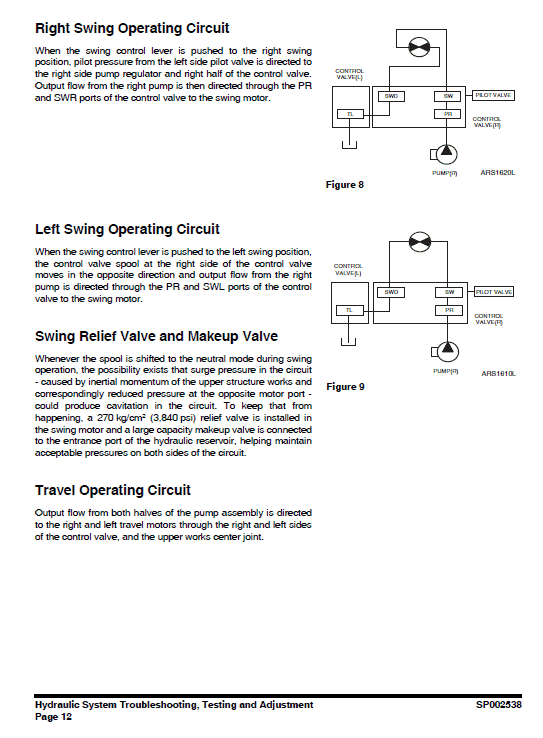

- Hydraulic System Troubleshooting, Testing, and Adjustment – SP002538

- Accumulator – SP002455

- Center Joint (Swivel) – SP002456

- Electrical System: Electrical System – SP002337, Electrical Schematic – SP002508

- Attachments: Boom and Arm – SP002513, Bucket – SP002506

Manual Instruction Extract

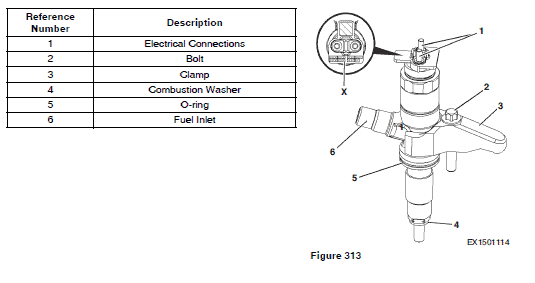

Fuel Injectors Overview

The electronic unit injectors require precise management of injector codes, programmable via the electronic control module (ECM). The fuel injectors operate without serviceable internal parts, except for the O-ring seal and combustion washer, ensuring faultless fuel atomization and injection into the combustion chamber.

The injection process is regulated by a two-way valve governed by the ECM, ensuring optimal fuel delivery and engine performance. Close pilot injections reduce NOx and noise, while main injections enhance engine torque and reduce smoke output in subsequent stages.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.