Takeuchi TB260 Compact Excavator Service Manual

Product Overview

The Takeuchi TB260 Compact Excavator service manual is an essential resource for operators and maintenance personnel. Comprising 702 pages, this comprehensive PDF manual provides detailed instructions on the operation, service, repair, and maintenance of the TB260 excavator. It includes valuable safety guidelines to ensure the proper and safe use of the machine. This manual applies to all applicable serial numbers (S/N).

Key Features

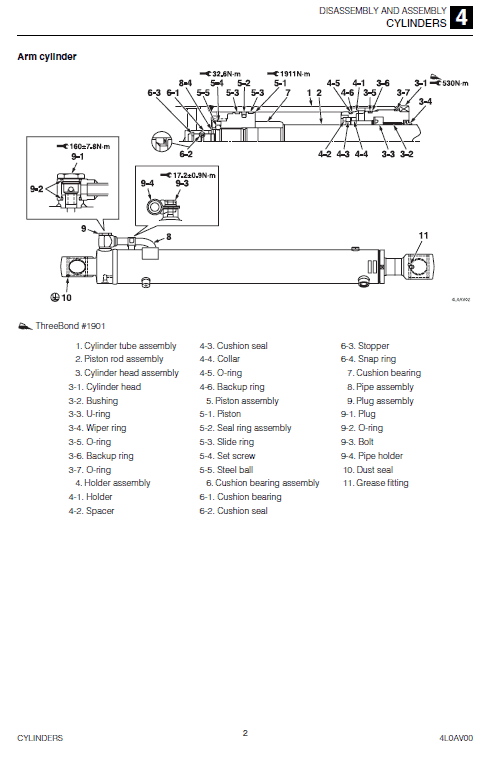

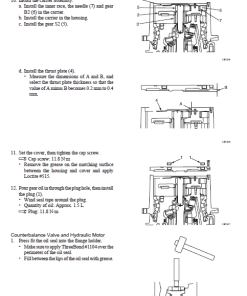

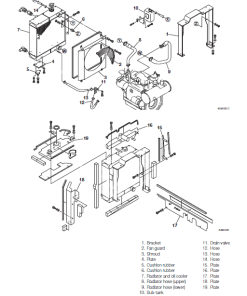

- Detailed instructions for disassembly and reassembly of the excavator.

- Comprehensive maintenance procedures and reference values.

- Troubleshooting guides and outline specifications.

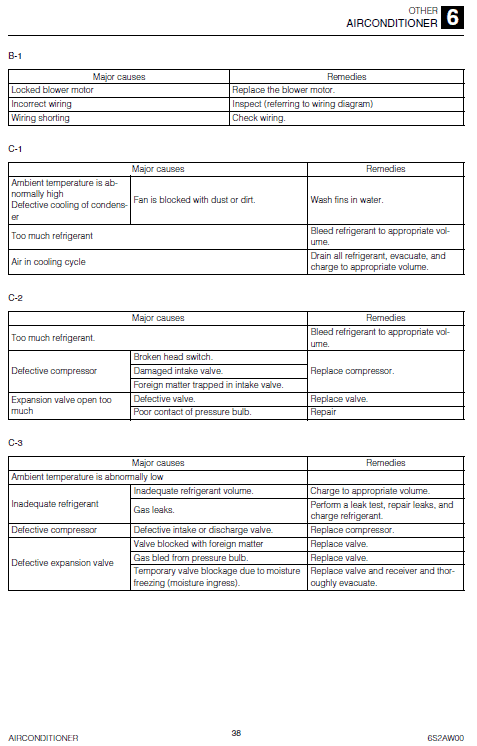

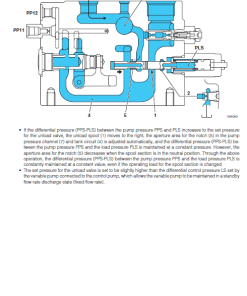

- Extensive coverage on hydraulic units, engine, and more.

Benefits

- Enhances maintenance techniques and ensures optimal performance.

- Provides step-by-step guidance for efficient troubleshooting.

- Serves as a reliable reference for service activities.

- Includes a table of contents for easy navigation.

Usage Recommendations

- Store the manual on the machine for quick access.

- Ensure all maintenance personnel are familiar with the content.

- Transfer the manual to the new owner when selling the machine.

- Conduct prescribed inspections before operating and address any issues promptly.

Table of Contents

The manual comprises the following sections:

- General

- Specifications

- Machine Configuration

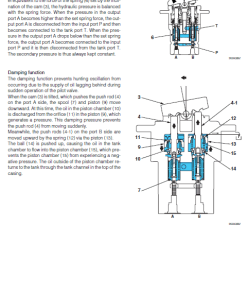

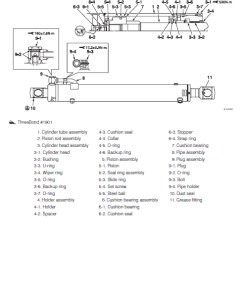

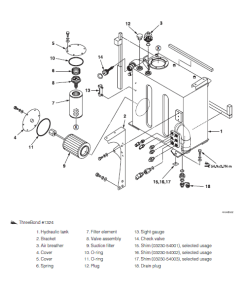

- Hydraulic Units

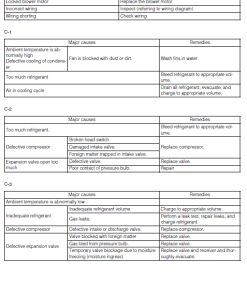

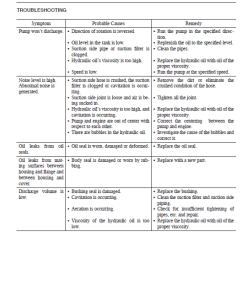

- Troubleshooting

- Engine

Important Notes

Please be aware that the contents and diagrams in this manual may not exactly correspond to your specific machine due to design modifications and updates. Always refer to this manual to improve your maintenance techniques and keep your excavator running efficiently.

Extract from the Service Manual

When the control lever is pulled slowly, the boom may temporarily drop. Follow these diagnostic steps:

- Check the load check valve in the control valve:

- Disconnect the control valve end of the hose from the boom cylinder.

- Connect it to the arm or bucket block and operate the boom cylinder.

- If the boom operates normally, the load check valve is likely faulty.

- Inspect for leakage inside the boom cylinder:

- Oil flowing from end A to end B may indicate a faulty piston or tube.

- This can lead to reduced drive force and significant spontaneous drop.

- Consult section 5 on Troubleshooting for further diagnostics.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.