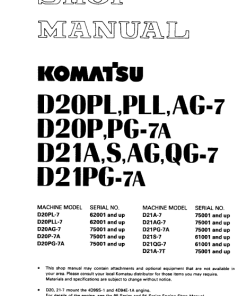

Maintenance Guide for Mechanical System SEN04227-00

Product Overview

This comprehensive maintenance guide is essential for ensuring the optimal performance of mechanical systems, specifically the SEN04227-00. Regular inspection and cleaning are crucial to prevent degradation in performance due to issues such as carbon accumulation.

Table of Contents

- 00 Index and Foreword

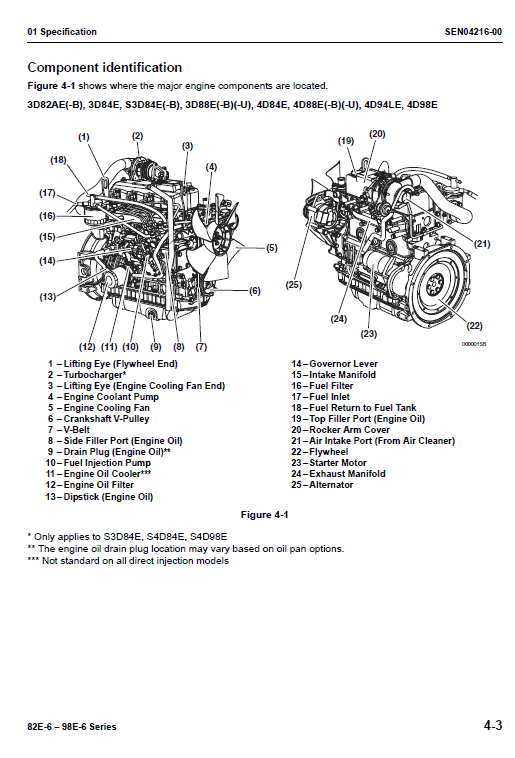

- 01 Specification

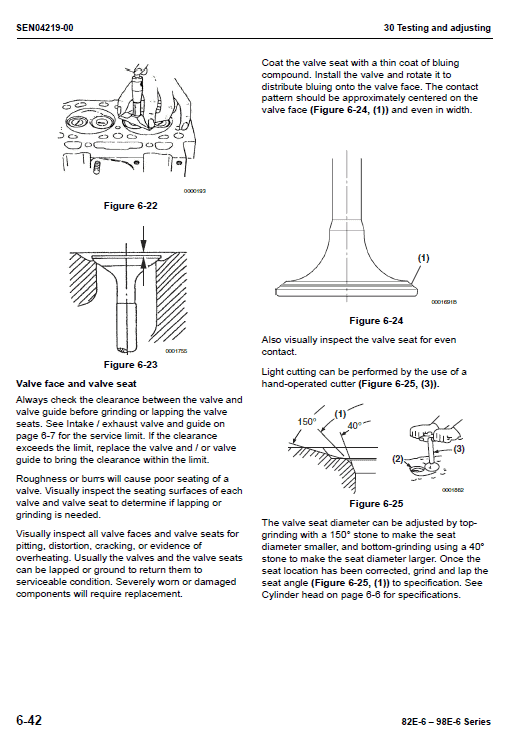

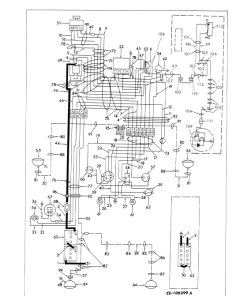

- 30 Testing and Adjusting

- 40 Troubleshooting

- Troubleshooting of Mechanical System SEN04227-00

- Special Service Tools – Page 15-217

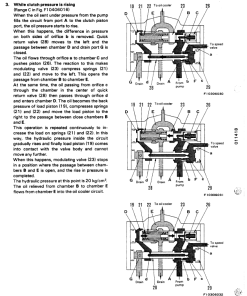

- Troubleshooting by Measuring Compression Pressure – Page 15-219

- Quick Reference Table for Troubleshooting – Page 15-222

- Failure Diagnostic List – Page 15-223

Key Features

- Detailed specifications and guidelines for the SEN04227-00 system.

- Comprehensive troubleshooting instructions with quick reference materials.

- Tools and techniques for precise testing and adjusting of the system.

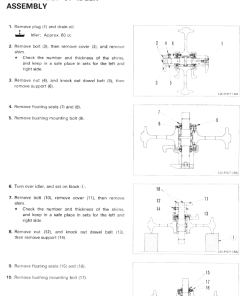

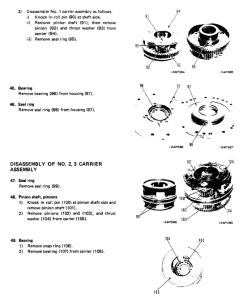

- Step-by-step maintenance procedures to maintain system efficacy.

Benefits

- Enhances system longevity and reliability through regular maintenance.

- Reduces downtime by providing systematic troubleshooting solutions.

- Ensures adherence to best practices in mechanical system care.

Usage Recommendations

- Inspect, clean, and test the exhaust gas recirculation (EGR) valve every 1500 operational hours to maintain performance.

- Focus on the EGR lead valve (models S4D84E-Z, S4D98E-Z) located in the recirculated gas passage to prevent carbon buildup.

- Perform regular maintenance to avoid clogging and ensure smooth valve operation.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.00

$34.50

Reviews

There are no reviews yet.