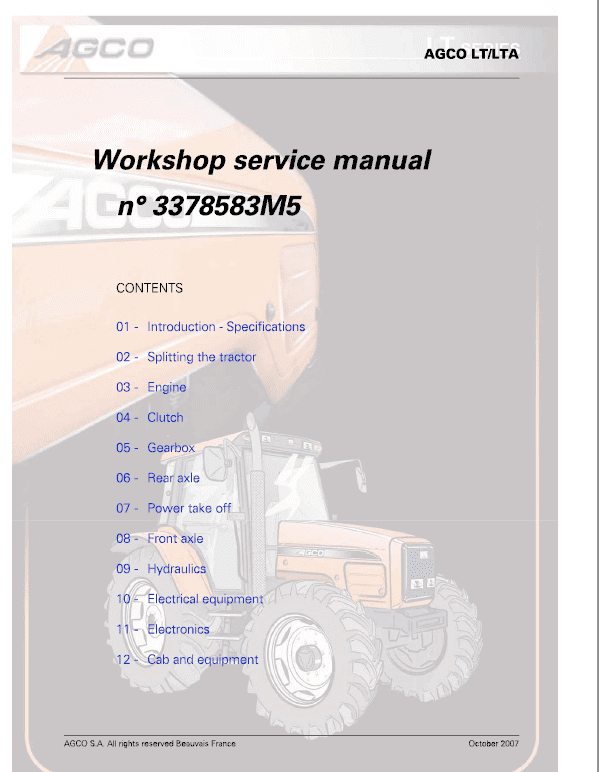

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00

AGCO LT Tractor Repair Service Manual

Access the comprehensive repair service manual for AGCO tractors, including models LT75, LT85, LT90, and LT95. This manual provides detailed information to assist with maintenance and repairs.

Manual Type: AGCO LT Tractor Repair Service Manual

Format: PDF

Book Number: 3378583M5

Language: English

Published: October 2007

Total Pages: 1959

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Service Manual

Product Overview

The AGCO LT Tractor Workshop Service Manual is an essential resource for the maintenance and repair of AGCO LT75, LT85, LT90, and LT95 tractors. This comprehensive manual, published in October 2007, contains detailed instructions and information spread over 1959 pages, making it a vital tool for both professional technicians and tractor owners.

Manufacturer: AGCO

Format: PDF

Language: English

Book Number: 3378583M5

Key Features

- Detailed specification and operation guidelines for AGCO LT Tractors.

- Comprehensive troubleshooting sections for key components.

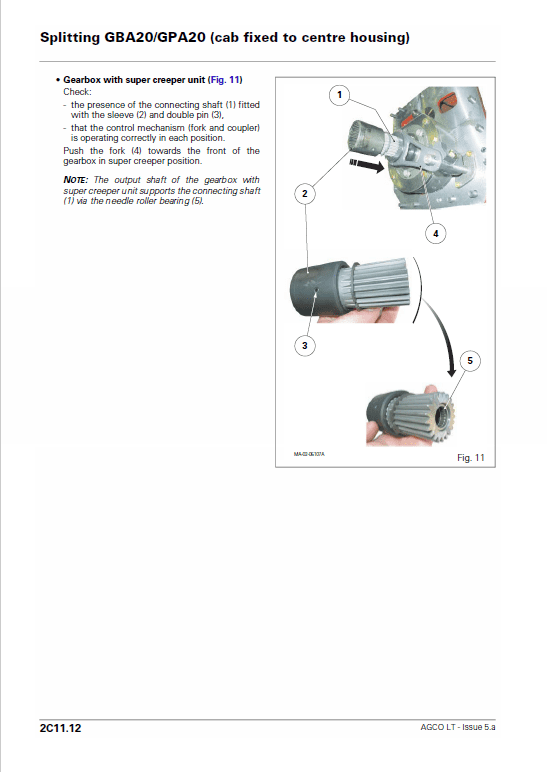

- Splitting and assembly guidance for tractor parts.

- Over 1900 pages filled with diagrams and illustrations.

Benefits

- Helps ensure optimal performance and longevity of tractors by providing precise repair techniques.

- Reduces downtime with step-by-step repair instructions.

- Improves understanding of tractor mechanics aiding in quicker diagnosis and repair.

Usage Recommendations

- Useful for professionals involved in the maintenance and repair of AGCO tractors.

- Ideal for tractor owners aiming to understand their vehicles better.

- Recommended for workshops and service centers as a reference manual.

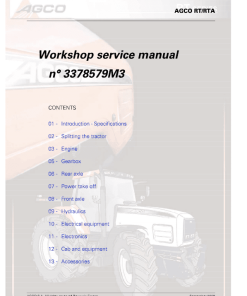

Manual Contents

- Introduction

- Specification

- Splitting the Tractor

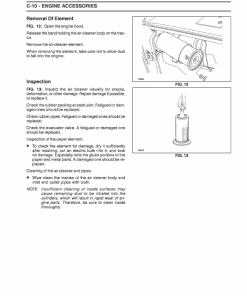

- Engine

- Clutch

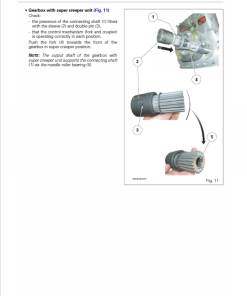

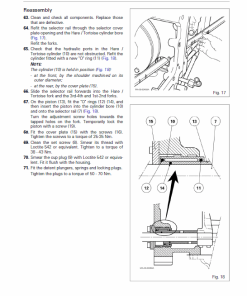

- Gearbox

- Rear Axle

- Power Take Off

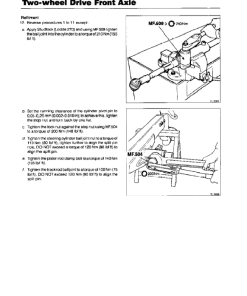

- Front Axle

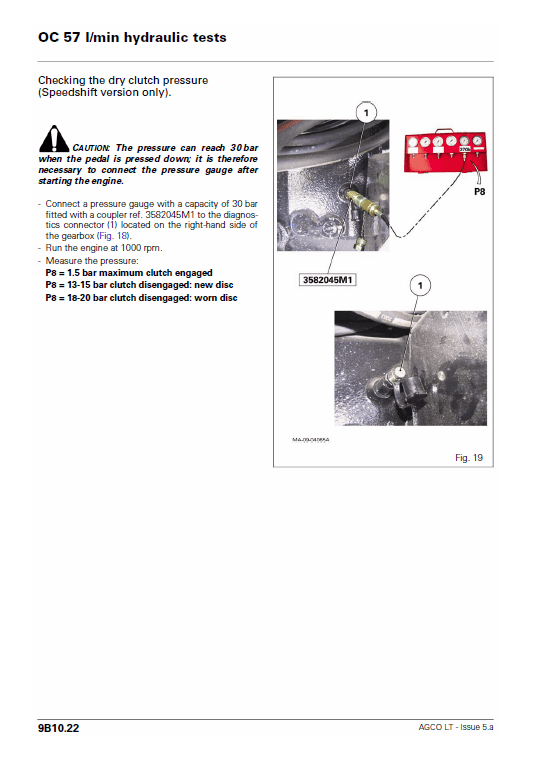

- Hydraulics

- Electrical Equipment

- Electronics

- Cab and Equipment

Mechanical Reverse Shuttle – AGCO LT75, LT85, LT90, LT95 Manual Extract

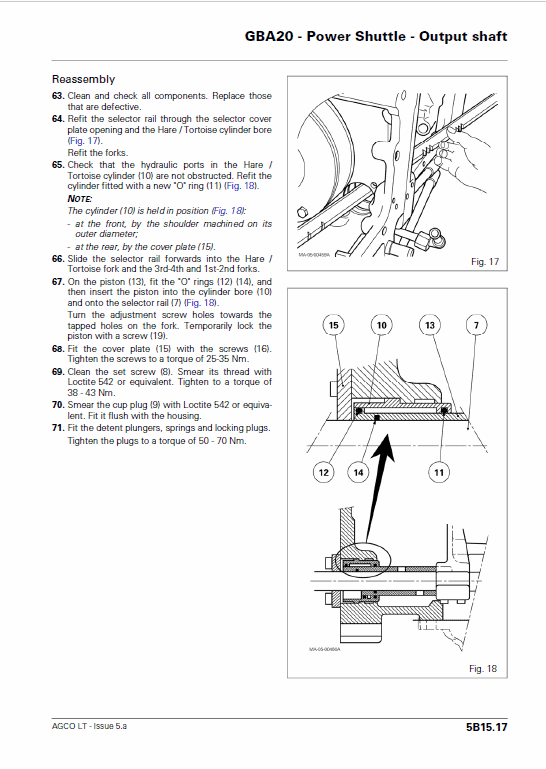

The GBA20 gearbox with mechanical reverse shuttle is designed to provide excellent performance and reliability. Its construction features three gear trains: the layshaft, intermediate shaft (or main shaft), and output shaft, facilitating eight basic synchronized gear ratios: four gear ratios (1st, 2nd, 3rd, and 4th) and two range ratios (Hare and Tortoise).

The gearbox’s highlights include the use of three single cone synchronizers and a system that allows the initial four gears to be expanded to eight with the aid of a gear idle-mounted on the output shaft. This construction promises smooth operation and reliable performance.

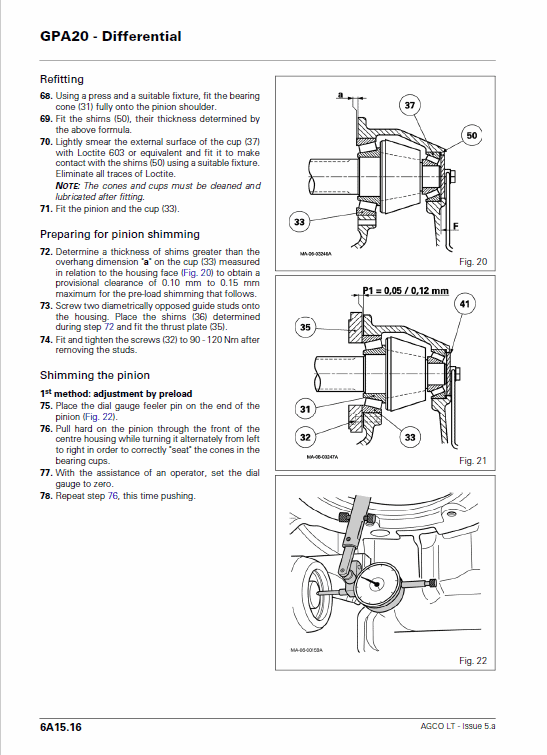

Bearings are crucial for reliability, with tapered roller bearings supporting the layshaft and intermediate shaft, and a combination of tapered and needle roller bearings supporting the output shaft. Precision fitting ensures stability and longevity, with bearings preloaded for the layshaft and set with clearance for the intermediate shaft, providing options for the output shaft as well.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.