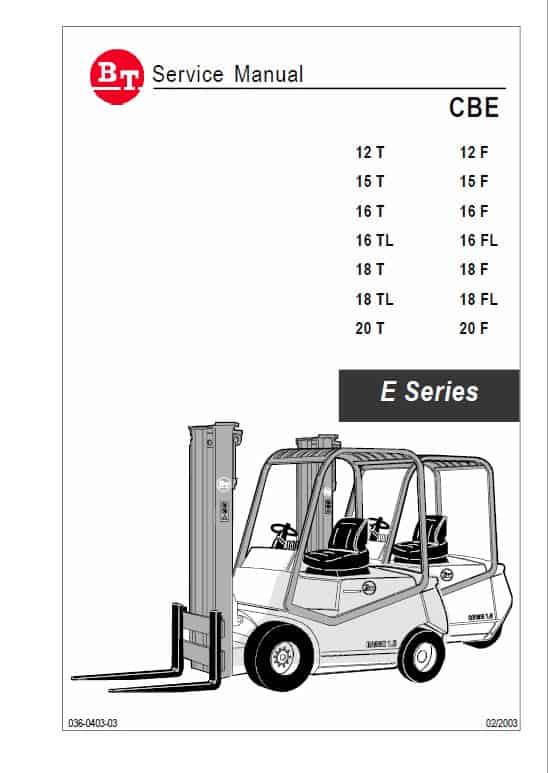

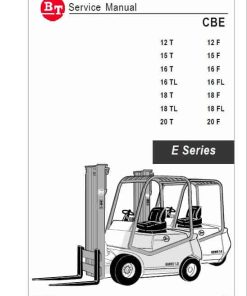

BT CBE 1.2F, CBE 1.5F, CBE 1.6F, CBE 1.6FL E Series Forklift Service Manual

$31.00

BT CBE E Series Forklift Service & Parts Manual

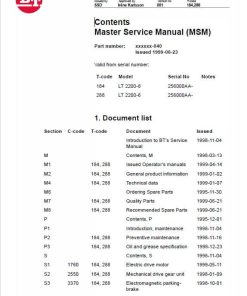

Enhance your BT CBE E Series Forklift maintenance with our comprehensive manuals. This package includes detailed service manuals for models CBE 1.2F, CBE 1.5F, CBE 1.6F, and CBE 1.6FL.

Service Manual: 194 and 104 pages

Parts Manual: 1682 pages

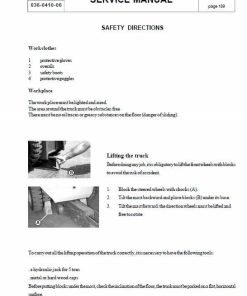

Publication number: 036-0410-06

Language: English

Year: 2004

Format: PDF

BT CBE E Series Forklift Manual

Product Overview

The BT CBE E Series Forklift Manual is a comprehensive guide for the following models: CBE 1.2F, CBE 1.5F, CBE 1.6F, CBE 1.6FL. This manual, published in 2004, is available in PDF format. It includes a detailed service manual spanning 194 and 104 pages, and an extensive parts manual with 1682 pages.

Key Features

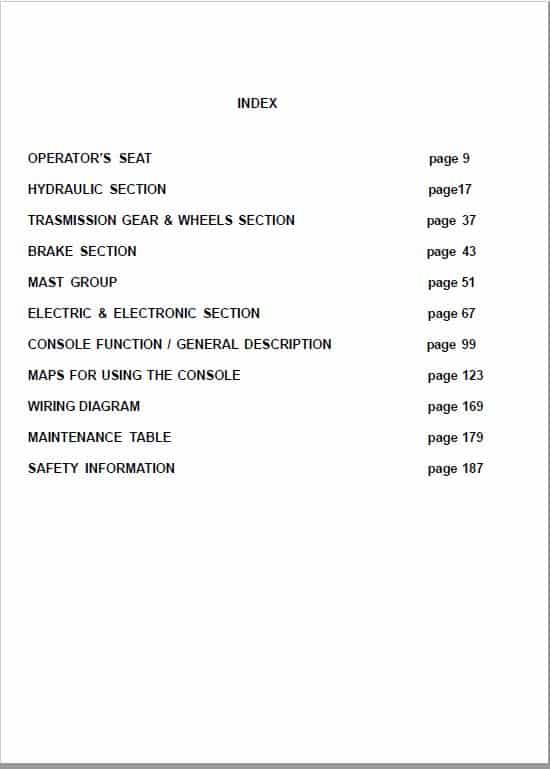

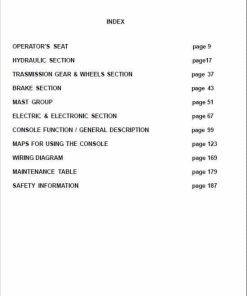

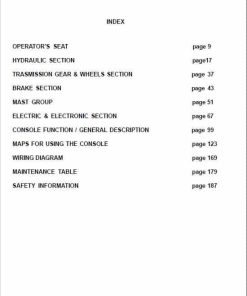

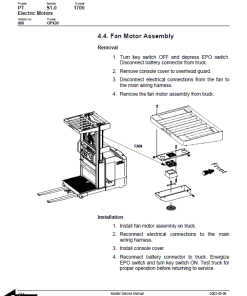

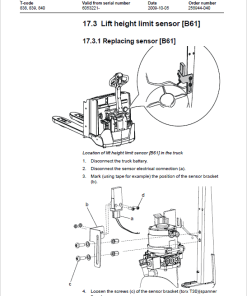

- Detailed operator’s seat instructions.

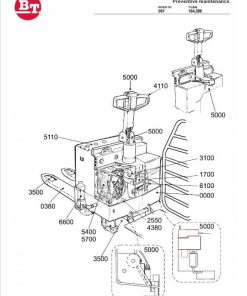

- Comprehensive hydraulic systems overview.

- Transmission gear and wheels maintenance guidance.

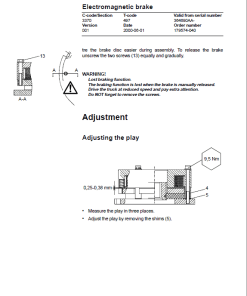

- Complete brake section including troubleshooting.

- Instructions for mast group maintenance and repair.

- Electric and electronic dashboard controls.

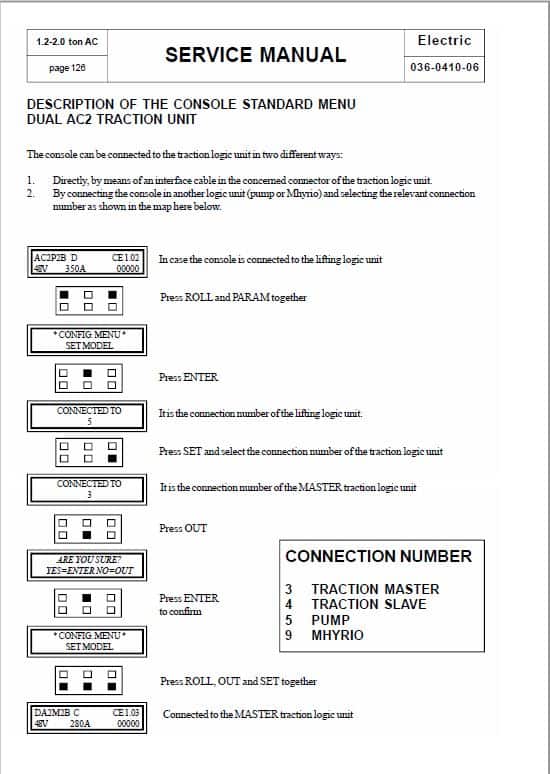

- Console function and general description guide.

- Maps and diagrams for console usage.

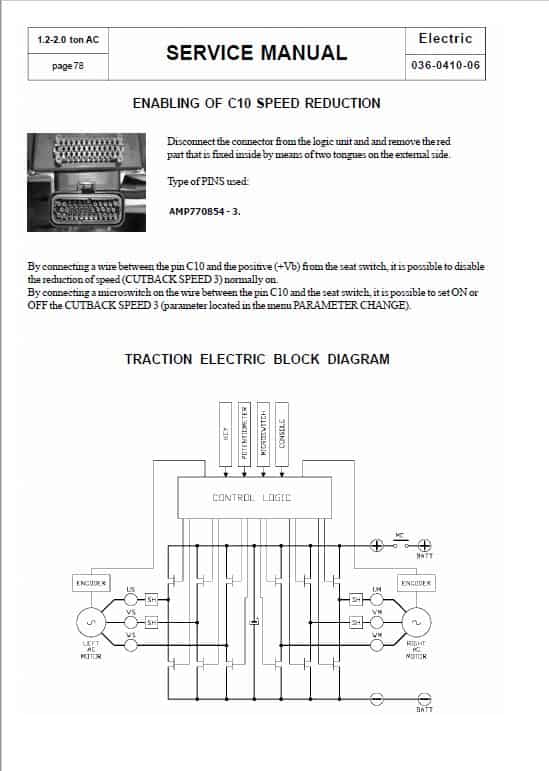

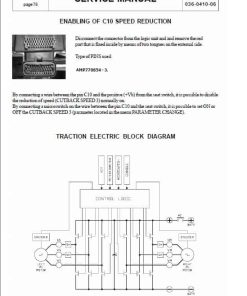

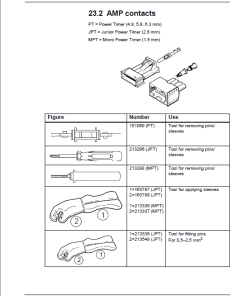

- Wiring diagrams for ease of maintenance.

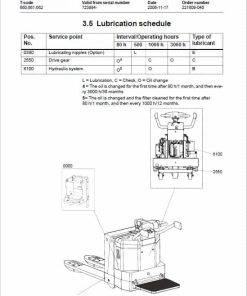

- Maintenance schedules and tables.

- Comprehensive safety information.

Benefits

- Ensures safe and efficient operation of the BT CBE E Series forklifts.

- Supports detailed dismantling and assembly of crucial components.

- Provides guidelines for oil changes and procedures in case of leakages.

- Assists trained personnel in executing complete overhaul tasks.

Usage Recommendations

- This guide is ideal for professional workshops with personnel trained in forklift maintenance and repair.

- Refer to the manual for detailed step-by-step instructions when performing routine maintenance.

- Conduct regular checks as per the maintenance table to ensure optimal performance.

- Utilize the safety information section to maintain the highest operational safety standards.

Dashboard Indicators

- Battery status indicator

- Parking brake ON warning light

- Brake fluid low level warning light

- Lifting speed reduction indication due to battery status

- “Dead man device” warning light

- Drive left motor temperature warning light

- Drive right motor temperature warning light

- Lifting motor temperature warning light

- Electronic hour meter and diagnostic code display

- Selected setting display: Low (L), Programmable (P), High (H)

- Low speed light indication

- Forward/backward and steering indication

- Light sensor for automatic adjustments

Hydraulic Oil Replacement

The hydraulic oil tank does not incorporate a drain plug. Follow two potential procedures for oil replacement:

- Use a pump connected to the oil level rod opening for oil discharge.

- Disconnect the drain hose of the control valve from the tank and direct it to an external container. Pressing the brake pedal facilitates oil flow, corresponding to the minimum RPM of the lifting pump. Ensure the pump does not operate without oil.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.