Engine Maintenance Manual

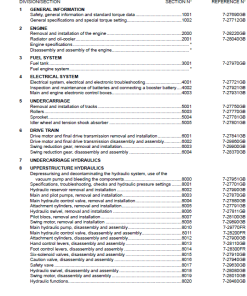

Table of Contents

- Specification

- Maintenance

- System

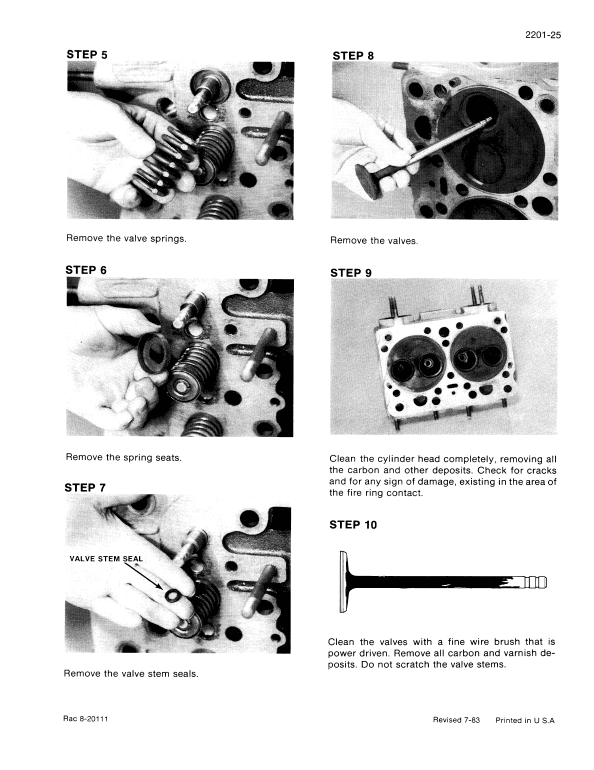

- Disassembling

- Troubleshooting

- Engine

- Installation Procedures for Optional Attachments

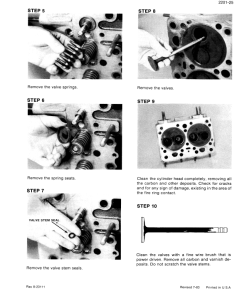

Manual Extract: Pressure Test Cylinder Block

Over time, engines may suffer from cylinder liner damage such as tight fitting, severe scoring, or overheating, which can lead to cracks in cylinder bores. Additionally, overheating can cause cracks between water jackets and oil passages.

To ensure optimal engine performance, it is crucial to pressure test the cylinder block for any cracks or leaks. This process can be conducted through either of the following methods:

Pressure Testing Methods

- Sealing Preparation: Plates must be fabricated to seal water openings at the top of the block. The main bearing caps should secure these plates using cylinder head bolts or studs and nuts.

- Gasket Installation: Use cylinder head seal rings as gaskets between the plates and the block. Water hole cover plates and gaskets are also necessary to seal the water pump inlet openings.

- Air Line Connection: Drill and tap one of the cover plates to create a fitting for an air line connection, ensuring thorough testing of the block for integrity.

Usage Recommendations

- Conduct regular maintenance checks to prevent overheating and liner scoring.

- Utilize proper tools and materials (e.g., fabricated plates, seal rings) for accurate pressure testing.

- Ensure all system components are correctly sealed to prevent leaks during operation.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.50

$34.00

$34.00

$33.00

$32.00

Reviews

There are no reviews yet.