Manual Extract Track Tension Adjustment Guide

Product Overview

This guide provides essential instructions for adjusting the track tension of machinery to ensure optimal performance and durability. Proper track tension adjustment is crucial for maintaining efficient operation and prolonging the lifespan of your equipment.

Key Features

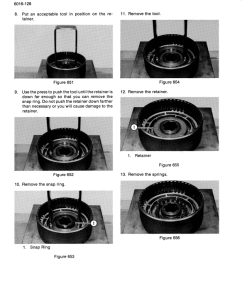

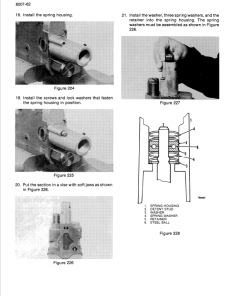

- Comprehensive step-by-step instructions for adjusting track tension.

- Suitable for most machinery with a track system.

- Guidelines for achieving precise track deflection measurements.

- Best practices for preparing the machine before adjustment.

Benefits

- Ensures the machine operates smoothly and efficiently.

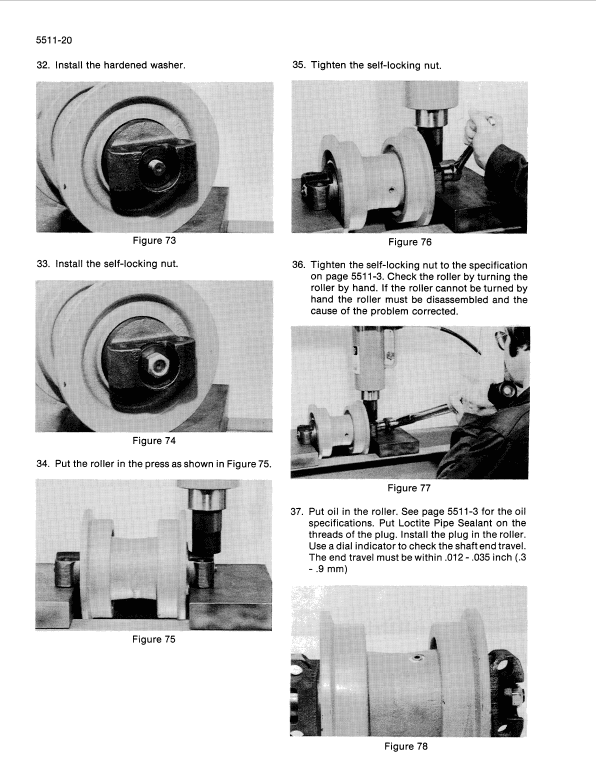

- Prevents excessive wear and tear on tracks and rollers.

- Reduces downtime by maintaining optimal track conditions.

- Enhances safety by ensuring machinery operates within recommended specifications.

Usage Recommendations

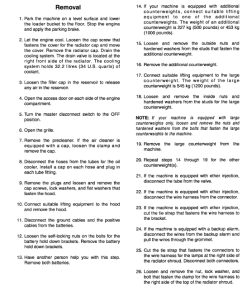

- Before adjustment, remove any mud and debris by operating the machine on a hard surface.

- Position the machine so that a chain pin is directly above the carrier roller.

- Apply body weight on the track between the carrier roller and the idler to verify maximum deflection.

- Use a straightedge to measure track deflection, which should be between 1 to 1-3/8 inches (25 to 35 mm).

- If deflection is not within the specified range, adjust the track using the following steps:

- To tighten the track, remove the plug from the track adjuster.

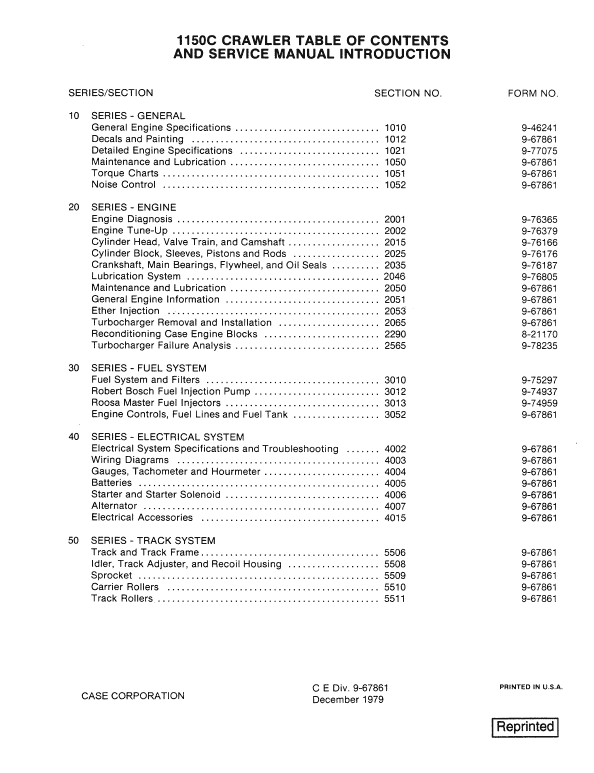

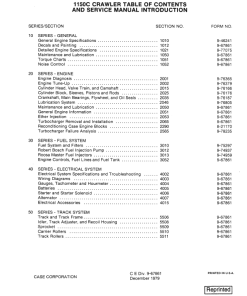

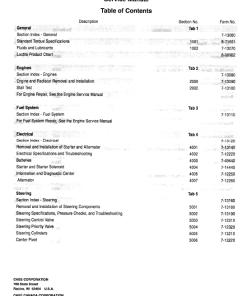

Table of Contents

- General

- Engines

- Fuel System

- Electrical System

- Track System

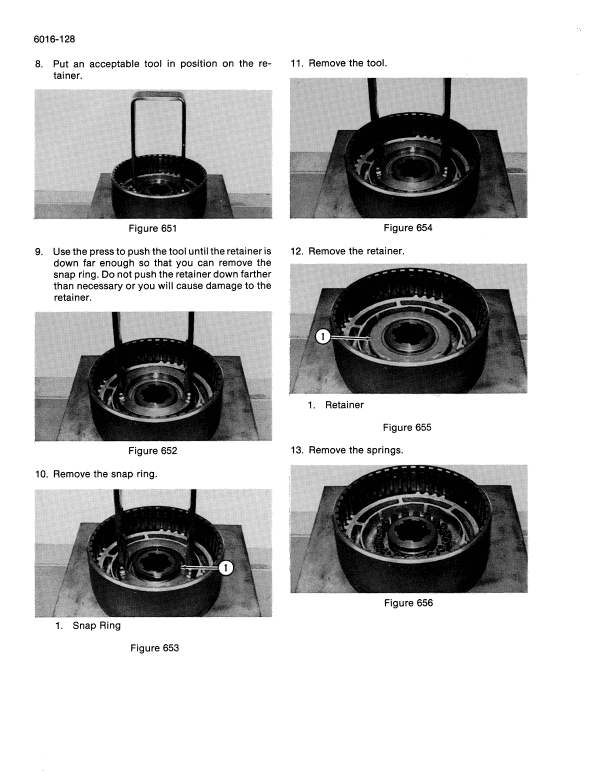

- Power Train

- Brakes

- Hydraulic System

- Mounted Equipment

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.00

$35.00

$34.00

$33.50

$32.00

$34.00

Reviews

There are no reviews yet.