Case 1270, 1370, 1570 Tractor Service Manual

$35.00

New Holland Tractor Service Manual

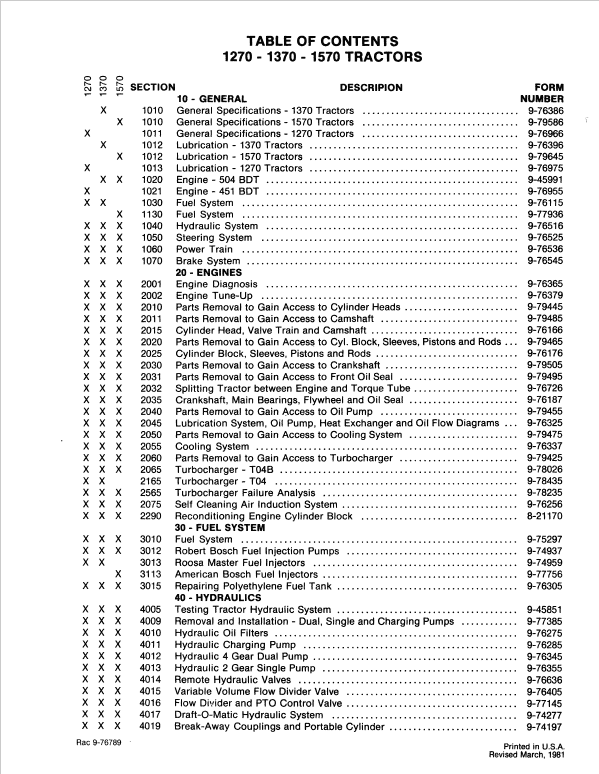

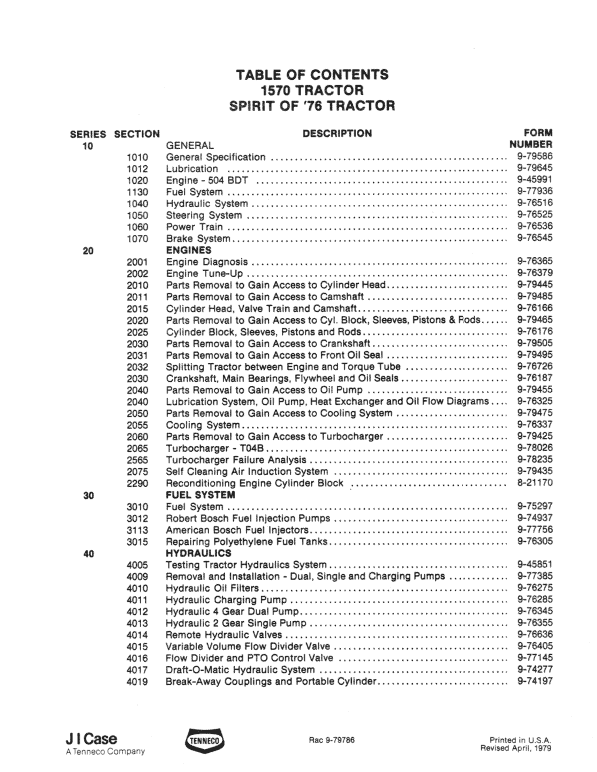

Discover the comprehensive New Holland service manual designed for models 1270, 1370, and 1570 tractors. This detailed manual is available in PDF format and includes 1652 pages and 1323 pages for extensive guidance.

Specifications:

Filter Replacement and Maintenance Manual

Product Overview

Welcome to the comprehensive guide for the maintenance and installation of filters in your machinery. This manual is designed to facilitate the seamless operation of your system by expertly guiding you through the process of filter removal and installation.

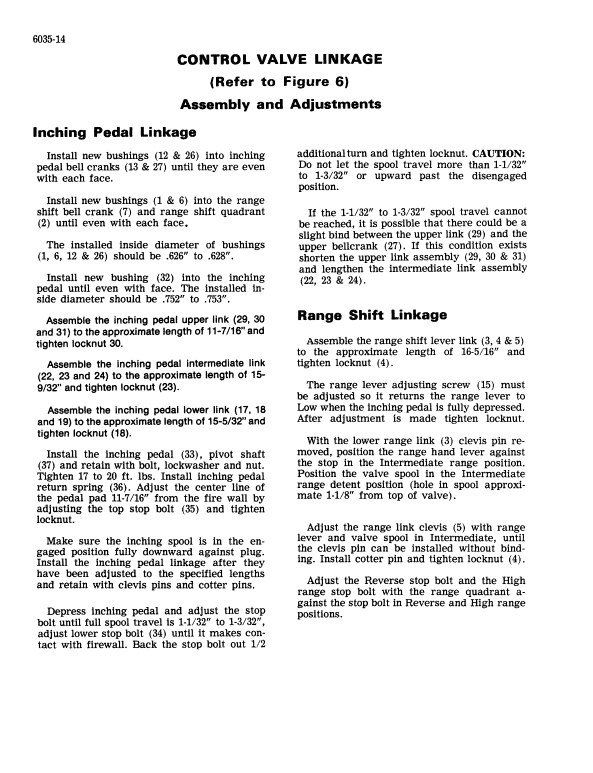

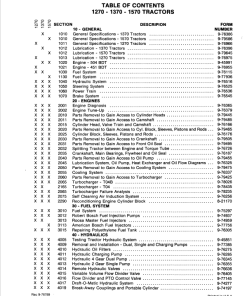

Table of Contents

- General

- Engine

- Fuel System

- Hydraulics

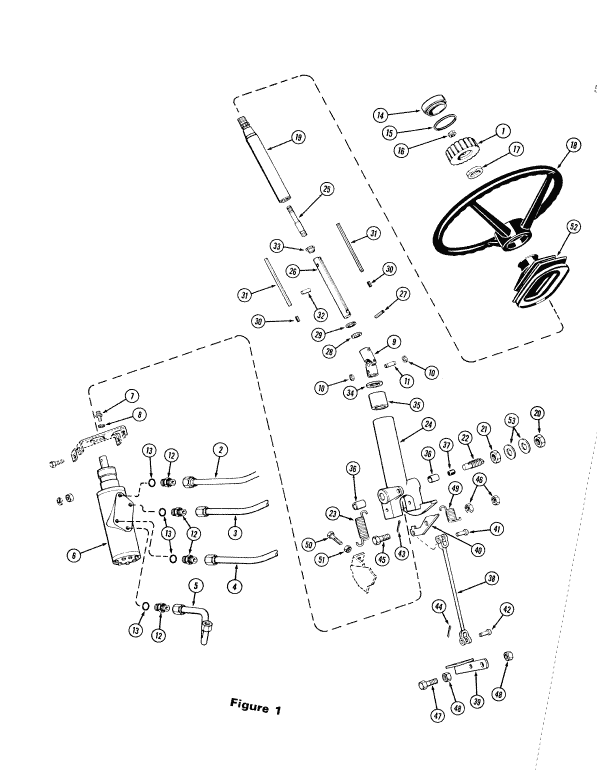

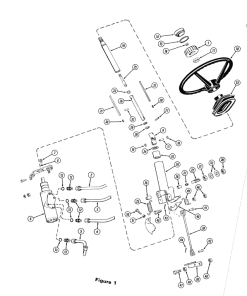

- Steering

- Power Train

- Brakes

- Electrical

- Accessories

- How It Works

Manual Extract: Filter Removal and Installation

- Close the fuel tank shut-off valve and remove the drain plug from the first stage filter.

- Use a clamp-type filter wrench or Case No. A64761 filter wrench to remove the filters by turning them counterclockwise.

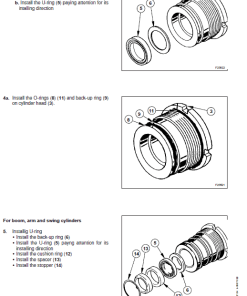

- Remove the stud gasket from the second stage filter mounting stud and replace it with a new gasket.

- Apply a thin film of oil or grease to the gaskets of the new first and second stage Case Filters. Install the filters by turning clockwise until the gasket contacts the filter head. Hand tighten an additional 1/2 turn. Loosen filters and retighten 1/2 to 3/4 of a turn after gasket contact to ensure a proper seal.

- Note: Excessive tightening may damage gaskets and filters.

- Loosen the bail locknut retaining the fuel bowl on the transfer pump preliminary filter. Swing the bail away and lower the bowl with the element, spring, and gasket. Replace the element if damaged or clean it with diesel fuel if reusable. Clean the bowl with clean diesel fuel and a lint-free cloth.

- Install the cleaned or new element with a new gasket and spring, slide the bail into place, and tighten the bail locknut finger tight.

- Fill the fuel tank and open the fuel tank shut-off valve.

- Use the hand primer pump until the preliminary filter bowl is filled with fuel.

- Open the bleed valve on the first stage filter and operate the hand primer pump until clear, bubble-free fuel appears, then close the valve.

- Repeat the bleeding process with the second stage filter, ensuring to operate the primer pump five additional times after the filter is bled. Securely tighten the hand primer pump handle before starting the engine.

- If power issues persist after bleed completion and filter replacement, check the fuel system pressure with a 0 to 50 PSI gauge in the injection pump’s inlet fitting. The pressure should be within 20 to 30 PSI. Adjust accordingly if outside this range.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.50

$35.00

$34.00

$34.00

$34.00

Reviews

There are no reviews yet.