Case 1850K Crawler Dozer Service Manual

$33.00

Manual Included: Comprehensive 465-page service manual.

Brand: New Holland

Model: 1850K

Type: Dozer

Manuals: Service Manual

Publication Number: 87388581A

Language: English

Format: PDF

High Pressure Pipes, Connections, and Hoses: Manual Guide

Product Overview

This comprehensive manual offers detailed procedures and best practices for the disassembly and maintenance of high-pressure pipes and their connections. Essential for ensuring the durability and functionality of your hydraulic systems, this guide provides clear instructions to prevent damage and ensure optimal performance during assembly and disassembly processes.

Key Features

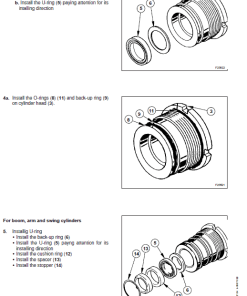

- Detailed step-by-step procedures for disassembling high-pressure pipes and connections.

- Guidelines for maintaining clean internal and external threads.

- Instructions on handling plugs and open connections to maintain system integrity.

- Specifications on the use of semi flanges, including acceptable deviation limits.

- Details on inspecting and lubricating O-Ring seats for enhanced sealing.

- Comprehensive advice on proper tightening methods to prevent damage.

- Best practices for installing and adjusting support bands during assembly.

Benefits

- Ensures longevity and proper functionality of your hydraulic systems.

- Prevents common assembly mistakes that could lead to costly repairs.

- Improves operational safety by following manufacturer-recommended practices.

- Facilitates easy and efficient disassembly, reducing downtime.

Usage Recommendations

- Always keep threads clean to ensure proper fitting and sealing.

- Remove protective plugs only before connecting the pipes to prevent contamination.

- Avoid reusing semi flanges that are more than 0.6 mm out of shape in the center.

- Inspect O-Ring seats meticulously for any damages before assembly.

- Lubricate O-Rings thoroughly to ensure smooth fitting and prevent leaks.

- Ensure O-Rings are correctly seated to avoid misalignment during tightening.

- Tighten connections gradually to prevent undue stress on O-Rings.

- Install pipes with support bands loosened and only tighten them after securing connections.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.50

$32.00

$34.00

Reviews

There are no reviews yet.