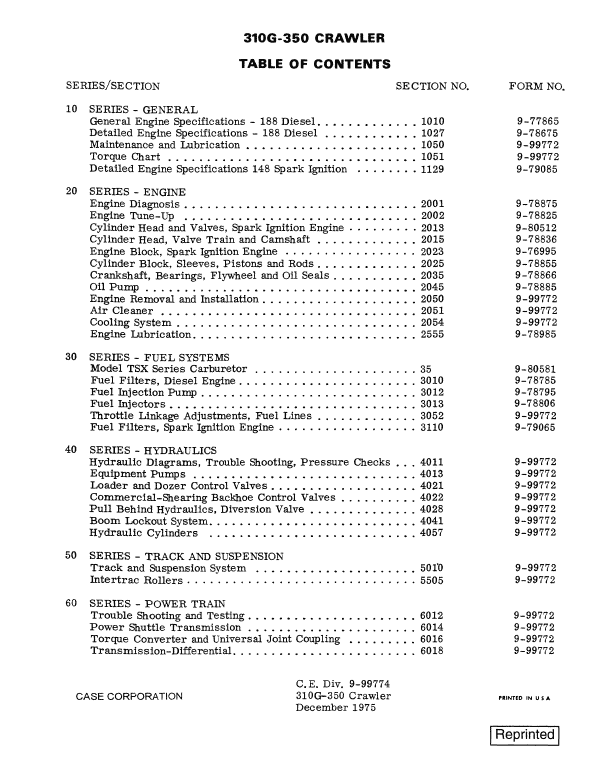

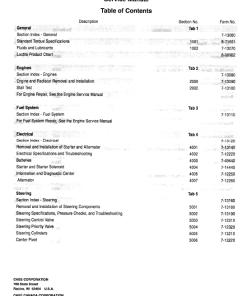

Manual Extraction: Flywheel, Oil Pan, Seal Retainer, and Oil Filter

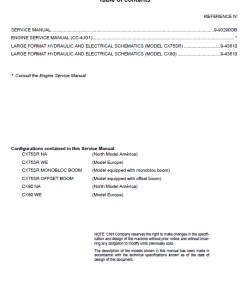

Product Overview

This detailed manual provides step-by-step instructions on the removal and maintenance of crucial components such as the flywheel, oil pan, seal retainer, and oil filter. Designed for use with various engine configurations, these procedures ensure a seamless servicing experience, helping you maintain optimal engine performance.

Key Features

- Comprehensive coverage of engine components.

- Step-by-step instructions for each part removal.

- Includes specific notes on timing marks alignment.

- Guidelines for handling worn or damaged components.

Benefits

- Ensures accurate and efficient maintenance processes.

- Prolongs the life of your engine by ensuring proper handling of components.

- Reduces the likelihood of installation errors with detailed guidance.

Usage Recommendations

- Ensure all necessary tools are available before starting the procedure.

- Carefully follow each step to avoid damage to engine components.

- Consult the manual when replacing adapters, plugs, or seals to ensure compatibility.

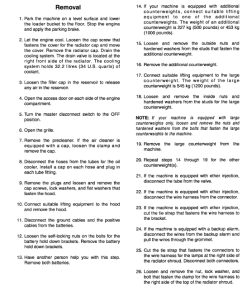

Important Steps:

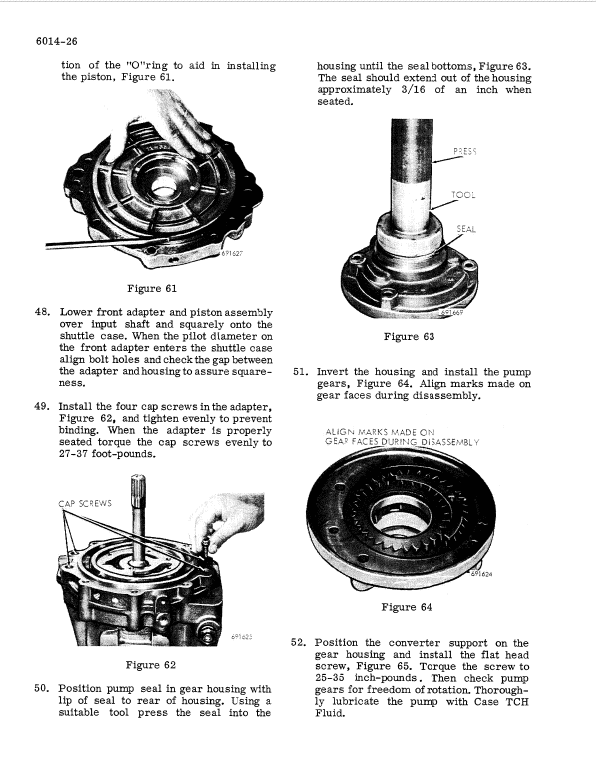

- Begin by removing the oil pan drain plug and gasket to drain the engine. Then remove and discard the engine oil filter.

- Detach the oil pan bolts and gasket, thoroughly clearing away all gasket material from both the block and oil pan.

- Disassemble the dipstick assembly if necessary, including the removal of any extension tube, “O” ring, and related components.

- If needed, replace the adapter and plug; ensure that proper operation is restored with new parts.

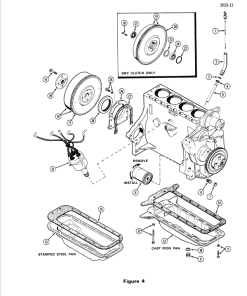

- Proceed to remove the flywheel mounting bolts and flywheel assembly. Replace the ring gear if it is worn or damaged.

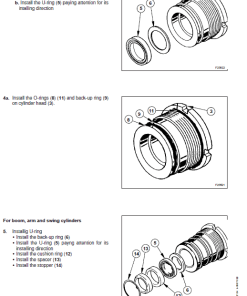

- For dry clutch tractor flywheel models, remove the oil seal, snap ring, “O” ring, and press out the bearing.

- Take out the rear oil seal retainer and gasket, and press the seal from the retainer.

- If necessary, remove and replace any cup plugs from the block by drilling and extracting them.

- Complete the procedure by removing the distributor as required.

Note: Engines with timing marks on the flywheel should have the flywheel rotated to align the TDC mark with the timing pointer. Make a mark on the front crankshaft pulley and timing cover for reference.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.50

$34.00

$34.00

Reviews

There are no reviews yet.