Case 3210, 3220, 3230 Tractor Service Manual

$34.00

New Holland 3200 and 4200 Tractor Service Manual

The comprehensive New Holland 3200 and 4200 Tractor Service Manual is an essential guide for maintenance and repair. This manual, spanning 843 pages, provides detailed instructions and specifications.

Service Manual: Comprehensive Guide

Product Overview

This service manual serves as an indispensable resource for understanding and maintaining various components of your machinery. It provides detailed instructions and specifications to ensure optimal performance and longevity of your equipment. Key sections within this manual are outlined below.

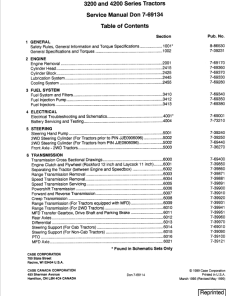

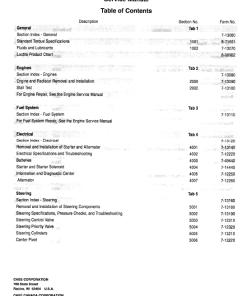

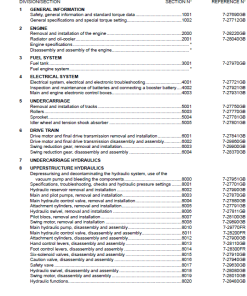

Table of Contents

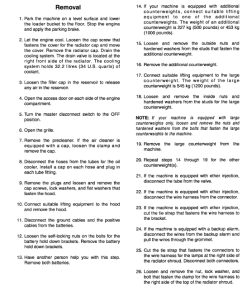

- General

- Engine

- Fuel System

- Electrical

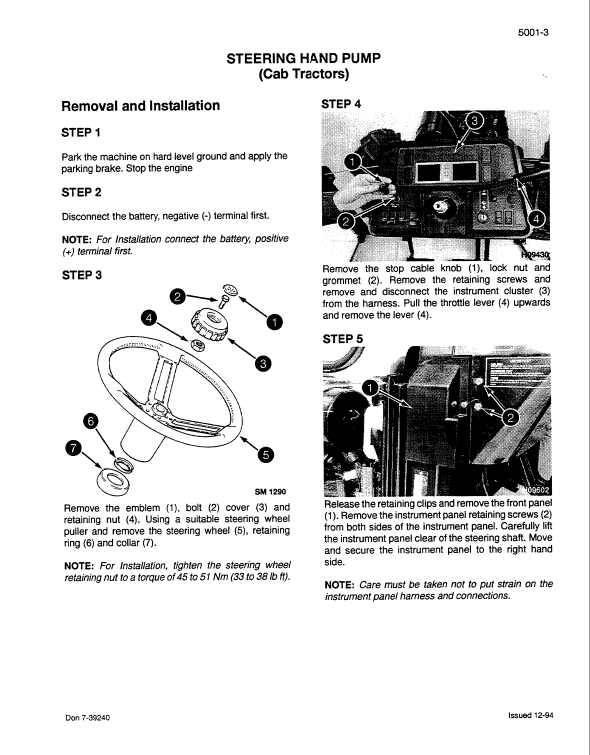

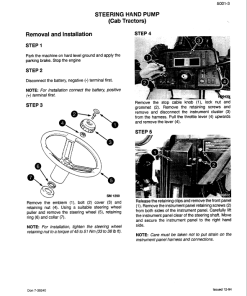

- Steering

- Transmission

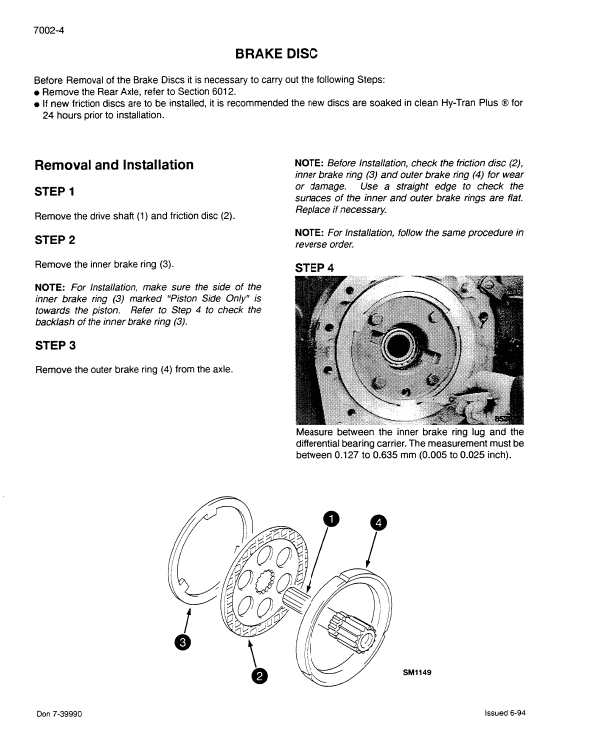

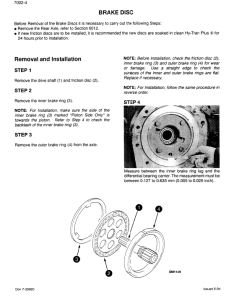

- Brakes

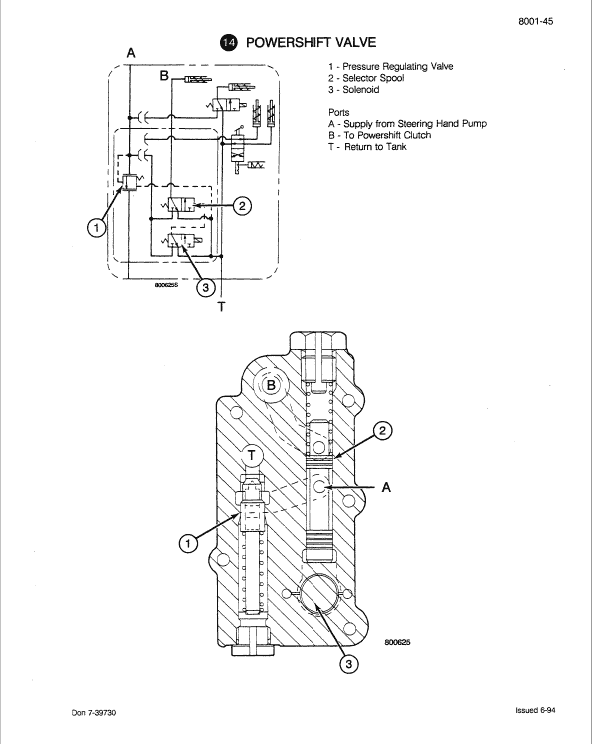

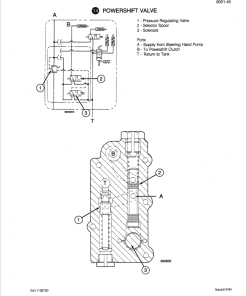

- Hydraulics

- Chassis and Mounted Equipment

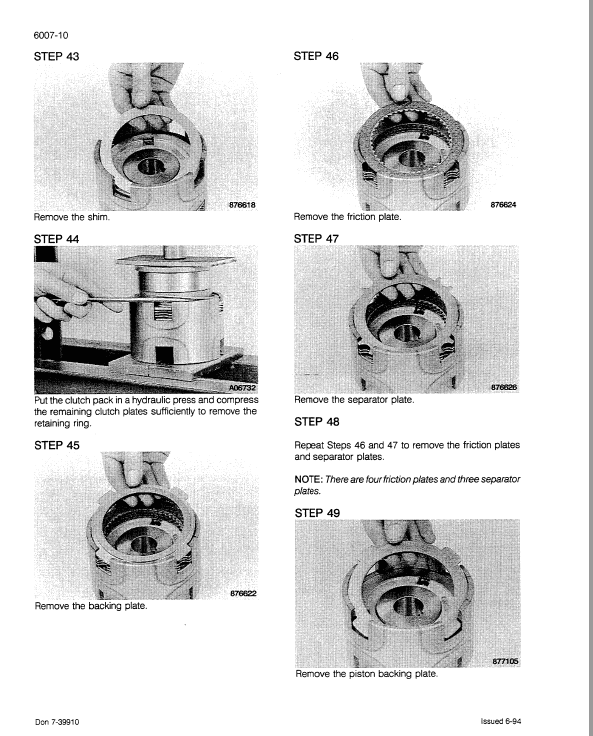

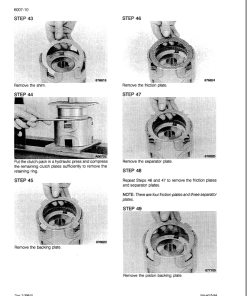

Manual Extract: Friction Plate and Pressure Plate Maintenance

This section focuses on the friction and pressure plates, providing crucial insights into their maintenance and inspection procedures.

Friction Plate

- Replacement Criteria: Replace if the friction material is less than 0.24 mm (0.01 inch) above the rivet heads.

- Contamination: If contaminated with oil, clean using a suitable solvent before reuse.

- Color Change: A blue color does not indicate excessive heat.

- Surface Wear: Flaking or cracking between rivets is normal and does not require replacement.

Pressure Plate

- Groove Tolerance: Can be reused if grooves are less than 0.64 mm (0.025 inch). Replace if grooves exceed this depth.

- Flatness Check: Must be replaced if flatness error exceeds 0.152 mm (0.006 inch).

- Refacing: It is important to note that refacing a pressure plate is not recommended.

Benefits

- Ensures machinery operates efficiently with detailed maintenance guidance.

- Helps identify necessary parts for replacement and maintenance, extending the life of your components.

Usage Recommendations

- Refer to the manual regularly to keep up with maintenance schedules and updates.

- Follow the safety and handling instructions carefully while performing any tasks outlined in the manual.

- Consult a professional if any procedures are beyond your skill level to ensure safe and effective maintenance.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$34.00

$34.00

$34.00

$33.00

$35.00

Reviews

There are no reviews yet.