Product Maintenance Manual

Overview

This maintenance manual provides detailed procedures for inspecting and maintaining various components to ensure optimal performance and longevity. Regular checks and corrections can significantly reduce the risk of machinery failure.

Table of Contents

- General

- Engine

- Electrical

- Steering

- Power Train

- Brakes

- Hydraulic

- Mounted Equipment

Manual Extract: Inspections and Checks

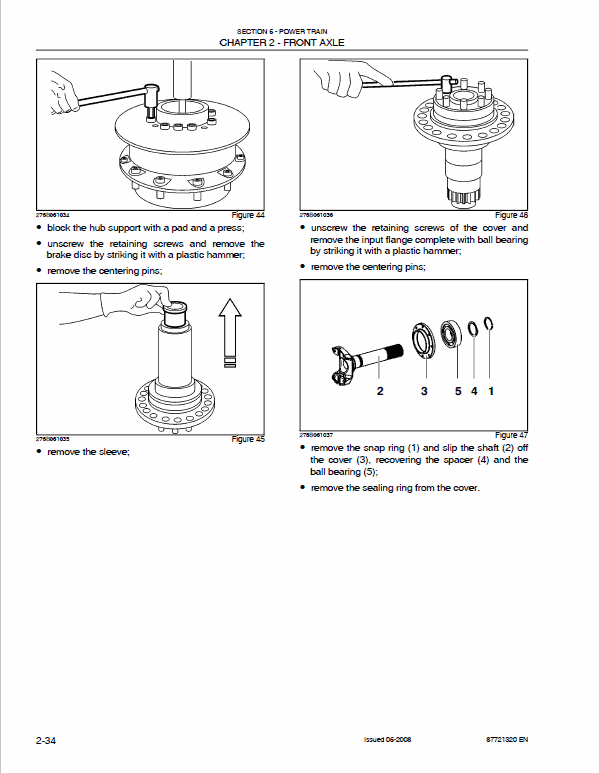

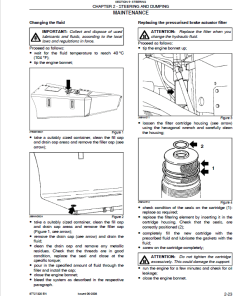

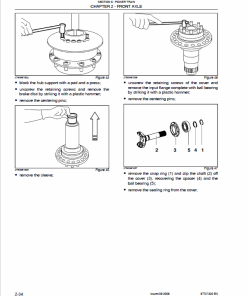

- Examine the boring and mounting surfaces for wear, scratches, or grooves. Replace any scratched or grooved components.

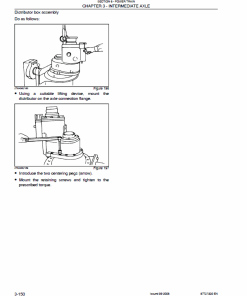

- Inspect all oil lines for obstructions. Clear blockages with compressed air or a smooth wire, followed by rinsing with solvent.

- Verify and correct damaged threads using a threading tap of the required dimensions.

- Inspect bearings for nicks, burrs, sharp edges, oval shapes, or signs of overheating. Replace any damaged bearings.

- Replace all washers to ensure component stability.

- Check grooves for deformation, chipping, or burrs. Replace the gear if defects are found.

- Inspect for burrs, damaged threads, and replace compromised components.

- Check springs for signs of overheating, permanent deformation, or wear from friction. Replace any defective springs.

Only logged in customers who have purchased this product may leave a review.

Related products

$35.00

$34.00

$35.00

$34.50

$33.50

Reviews

There are no reviews yet.