Case 340 Articulated Truck Maintenance Guide

Product Overview

This comprehensive manual provides detailed instructions for the maintenance and repair of the Case 340 Articulated Truck. It covers multiple sections that ensure safe and efficient handling of various components such as axles, brakes, and hydraulic systems. This guide is essential for technicians and operators who need to maintain the truck’s performance and longevity.

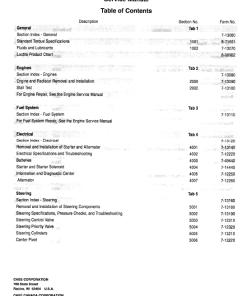

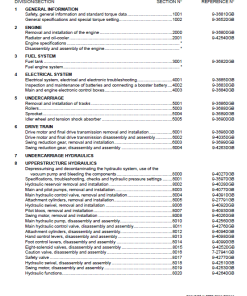

Table of Contents

- Content and Safety Instructions

- Technical Data

- Specification and Troubleshooting

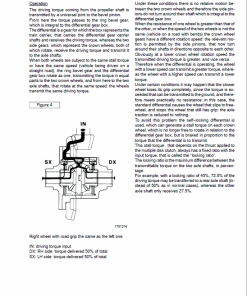

- Driveline

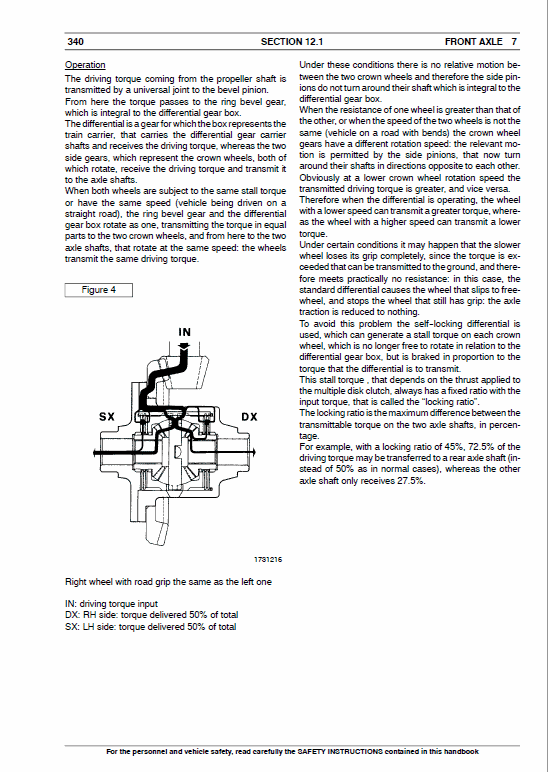

- Front Axle

- Intermediate Axle

- Rear Axle

- Brakes, Wheels, and Tires

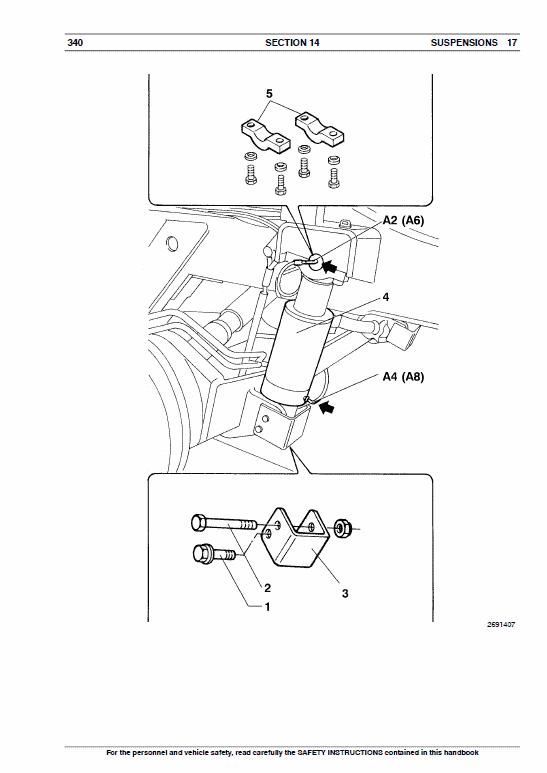

- Suspension

- Hydraulic System

- Pneumatic System

- Electrical System

- Cab and Chassis

- Air Conditioning

Key Features

- Step-by-step instructions for safe and effective maintenance.

- Comprehensive details covering all essential systems of the truck.

- Clear, professional guidance for both novice and experienced technicians.

Benefits

- Ensures the longevity and optimal performance of the Case 340 Articulated Truck.

- Reduces downtime by providing precise troubleshooting techniques.

- Promotes safety through detailed content and safety instructions.

Usage Recommendations

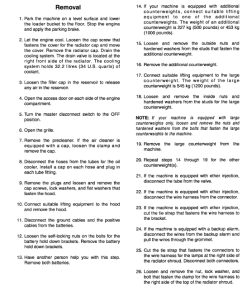

- Ensure the vehicle is on a flat, solid surface before maintenance begins. Switch off the engine, remove the ignition key, and engage the parking brake.

- Disconnect battery terminals or deactivate the battery isolator to avoid short circuits.

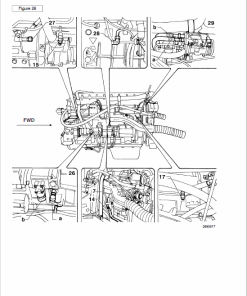

- Block articulation with the steering lock bar as instructed in SECTION 1.2.

- Use supporting trestles under the front chassis to raise the vehicle without engaging the suspension.

- Employ suitable hydraulic devices under the intermediate and rear axles to facilitate lowering and removal.

- Follow SECTION 13 for wheel removal, ensuring safety and adherence to procedure.

- Disconnect necessary electrical and pneumatic connections, and use appropriate plugs for hydraulic pipes to prevent leakage.

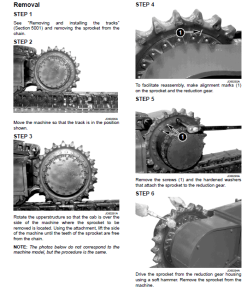

- Remove specified propeller shafts, bolts, and axle components as guided, maintaining proper sequence and safety protocols.

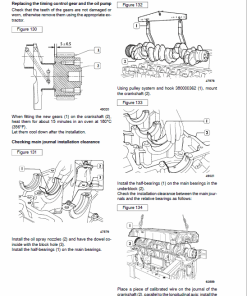

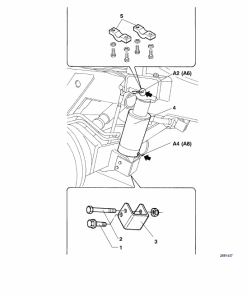

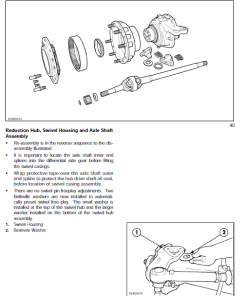

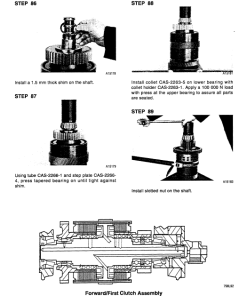

Manual Extract: Input Shaft

For detailed procedures on the disassembly and inspection, refer to the indicated sections within the manual and follow outlined safety measures.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$33.00

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.