Case 521E Loader Service Manual

$34.00

Case 521E Loader Service Manual

Manual Included:

- Service Manual: 896 pages & 898 pages

Specifications:

Brand: Case

Model: 521E

Type: Loader

Manuals: Service Manual

Publication Numbers: 84243970 (Feb 2008) & 84186213 (Jan 2009)

Language: English

Format: PDF

Comprehensive Guide to Hydraulic System Maintenance

Product Overview

This guide provides essential information on maintaining the hydraulic system of your machinery, focusing on

preventing and managing contamination. Understanding how contamination affects hydraulic components is crucial to

ensuring optimal performance and longevity of your equipment.

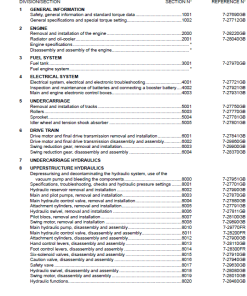

Key Features

- General Guidelines: Provides comprehensive instructions on system maintenance.

- Engine Insights: Offers detailed information on engine-specific processes.

- Fuel System Maintenance: Covers best practices for fuel system care.

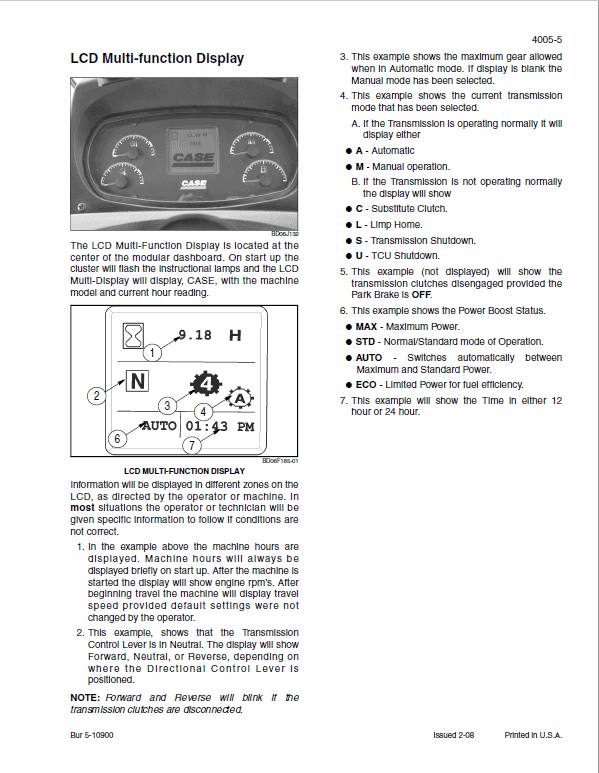

- Electrical System Care: Includes tips for maintaining electrical components.

- Steering Mechanics: Details on efficient steering system maintenance.

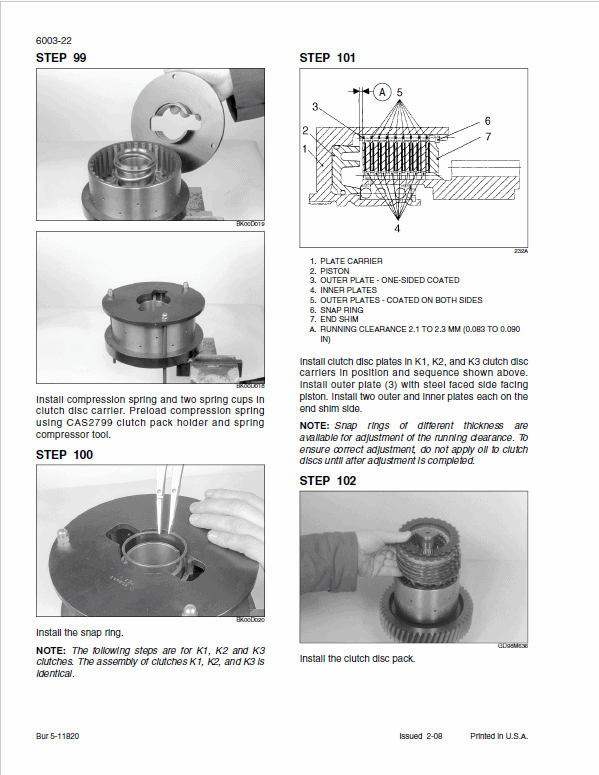

- Power Train Dynamics: Guides on effective power train management.

- Brake Functionality: Insight into maintaining brake efficiency.

- Hydraulics Focus: Specialized section on hydraulic system upkeep.

- Mounted Equipment Handling: Best practices for managing mounted equipment.

Benefits

- Enhanced Performance: Prevents common hydraulic system issues through proactive measures.

- Increased Equipment Longevity: Reduces wear and tear by maintaining system cleanliness.

- Cost Efficiency: Minimizes repair costs by addressing contamination early.

- Safety and Reliability: Ensures safe operation of machinery through proper maintenance.

Hydraulic Contamination

Contamination within the hydraulic system is a leading cause of hydraulic component malfunctions. Contaminants can enter

the hydraulic oil in various ways, such as:

- Draining or disconnecting oil lines.

- Disassembling components.

- Normal wear and tear of hydraulic parts.

- Damaged or worn seals.

- Faulty components within the system.

While all systems operate with some level of contamination, excessive amounts can cause significant issues, including r

leaking cylinder rod seals, control valve malfunctions, excessive heat generation, rapid wear of pump parts, r

and slow cycle times, resulting in inadequate power levels.

Usage Recommendations

- Regularly inspect hydraulic oil for signs of contamination.

- If contamination is detected, use a Portable Filter to cleanse the system.

- Monitor component seals and replace them when worn or damaged.

- Be vigilant about potential system wear and component damage.

Maintaining a clean hydraulic system is critical for efficient and reliable machinery operation. Address contamination issues promptly

to ensure the longevity and performance of your equipment.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.