Comprehensive Maintenance Guide

Table of Contents

- Introduction

- Engine

- Transmission

- Front Axle

- Rear Axle

- Brakes and Controls

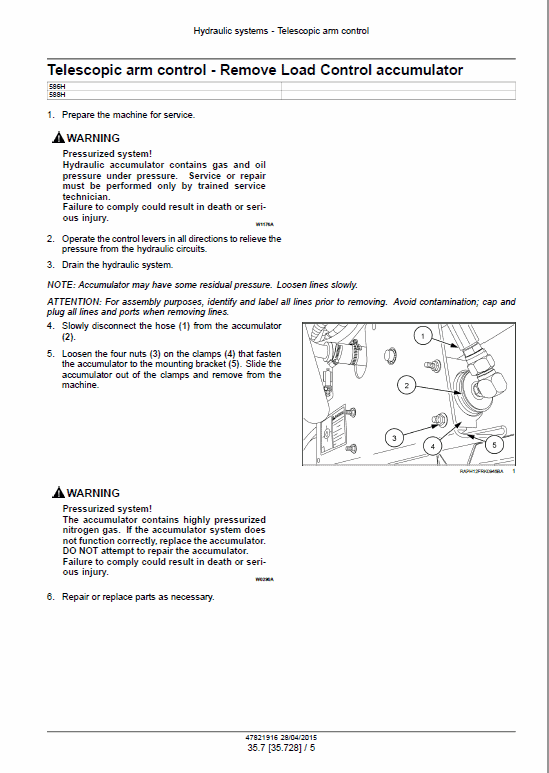

- Hydraulic Systems

- Frames and Ballasting

- Steering

- Wheels

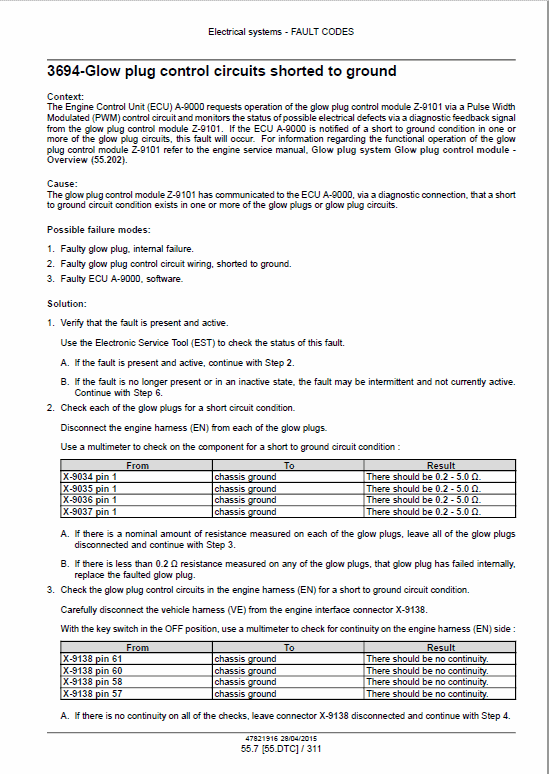

- Electrical System

- Telescopic Single Arm

- Platform, Cab, Bodywork and Decals

- Special Tool Index

- Electrical Schematic

- Hydraulic Schematic

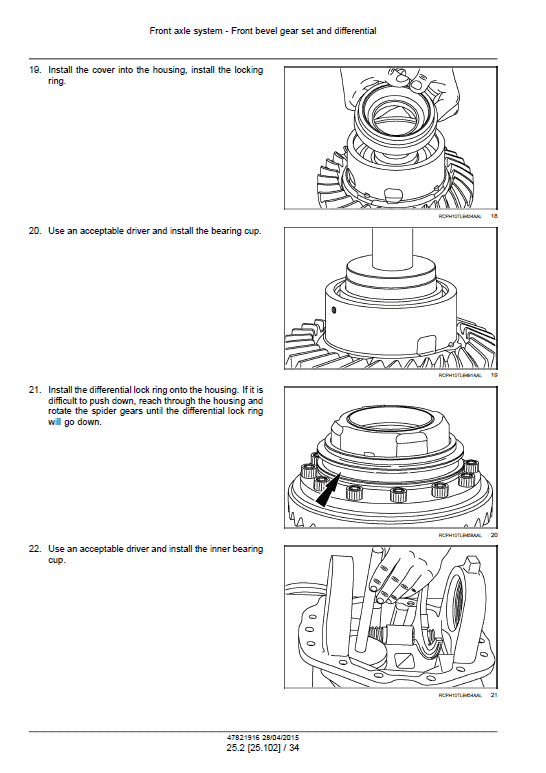

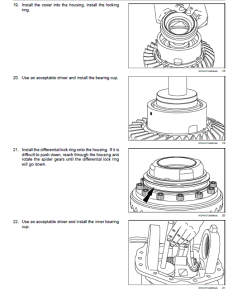

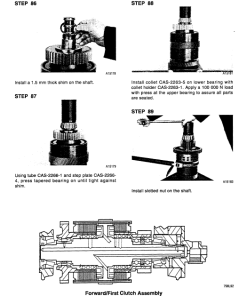

Manual Extract: Differential Inspection

Follow these detailed steps to ensure the proper maintenance and inspection of the differential components:

- Cleaning: Begin by cleaning all differential parts thoroughly using a suitable cleaning solvent.

- Bearing Examination: Check the bearing cups and rollers for signs of wear such as flat areas, pitting, scoring, or any other damage. Inspect the inner race carefully. Replace the bearing and bearing cup if any defects are found.

- Gear Teeth Inspection: Examine the teeth on both the pinion and ring gears for damage. Look for pitting, scoring, or broken teeth. Remember, if replacement is necessary, the ring and pinion gear must be replaced together as a set.

- Side Gear and Pinion Shaft Review: Investigate the condition of the side gears and the pinion shaft along with the pinion gear teeth. Check for pitting, scoring, and wear. Additionally, inspect the thrust surfaces and the bore of each pinion gear. Consider replacing parts as needed due to wear and tear.

- Thrust Washer Assessment: Ensure the thrust washers are free from pitting, scoring, and damage. Replace with new components if they are worn or damaged.

Key Features

- Detailed inspection procedures for differential components.

- Comprehensive guidelines for cleaning and assessment.

- Recommendations for part replacements based on wear and damage.

- Clearly outlined contents for easy navigation.

Benefits

- Enhances equipment longevity by ensuring proper maintenance.

- Reduces risk of unexpected failures and repairs.

- Improves safety and performance standards.

- Facilitates organized and systematic maintenance checks.

Usage Recommendations

- Regularly inspect differential components as part of a routine maintenance schedule.

- Use appropriate cleaning solvents and tools as recommended in the guide.

- Ensure all inspections and replacements are documented for future reference.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.50

$34.00

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.