Case 680CK Loader Service Manual

$36.00

Case 680CK Loader Service Manual

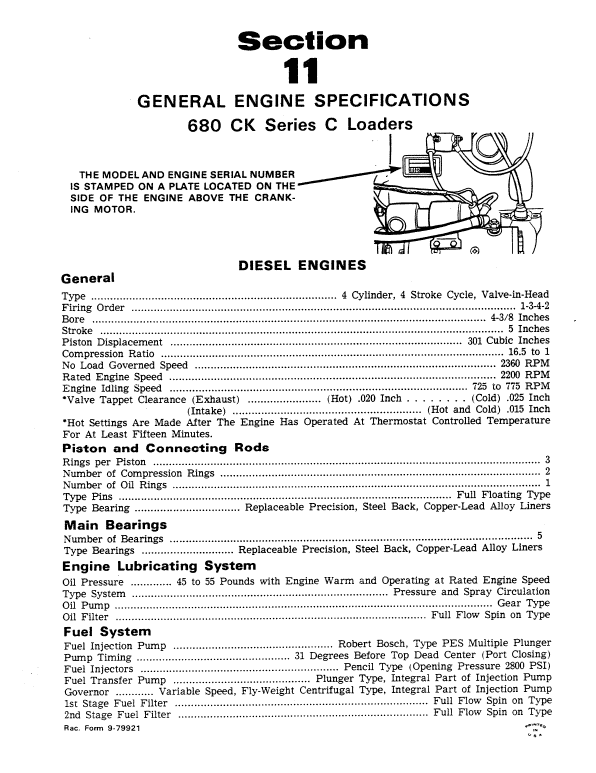

Enhance your understanding of the Case 680CK Loader with this comprehensive service manual. This resource covers the 680CK, 680CK Series C, and 680CK Series E models, and is available in English as a PDF.

Manual Details:

- Pages: 498, 623, and 706

- Brand: Case

- Type: Loader

- Publication Number: 9-72595

Access and download your service manual to keep your loader in optimal condition.

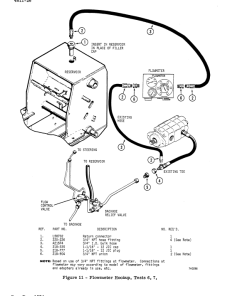

Mechanical System Cylinder Check Guide

Product Overview

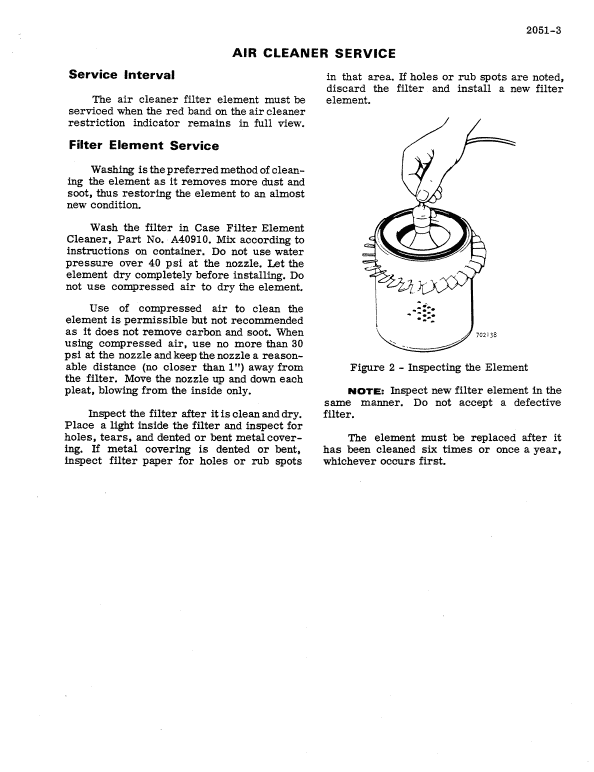

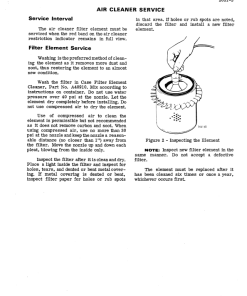

This guide provides vital instructions for conducting maintenance checks on various mechanical cylinders, including loader lift, tilt, and other cylinders within hydraulic systems. Ensuring your equipment operates smoothly requires a thorough understanding of these procedures.

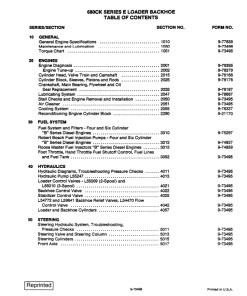

Table of Contents

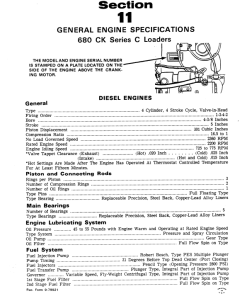

- General

- Engines

- Fuel System

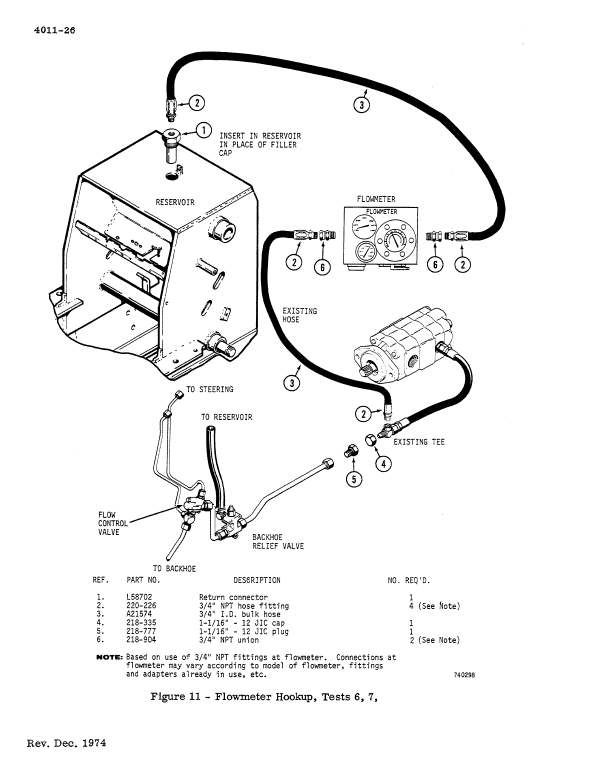

- Hydraulics

- Steering

- Power Train

- Brakes

- Electrical

- Mounted Equipment

Key Features

- Comprehensive procedural guidance for checking mechanical cylinders.

- Step-by-step maintenance instructions to ensure system efficiency and safety.

- Detailed troubleshooting tips for identifying and repairing cylinder issues.

Benefits

- Enhanced equipment longevity through proper maintenance practices.

- Improved safety for operators by ensuring all cylinders are functioning correctly.

- Reduced downtime thanks to early identification and rectification of issues.

Usage Recommendations

- Loader Lift Cylinders: Place the machine on blocks to fully retract lift cylinders. Turn off the engine before removing the tube at the cylinder’s closed end.

- Tilt Cylinders: Completely retract these cylinders and shut off the engine. Disconnect the hose at the closed end.

- Other Cylinders: Run each cylinder to its end stroke before engine shutdown. Use supports if necessary, then disconnect the return-side hose or tube.

- Testing for Leakage: Restart the engine at half throttle, engage the control lever, and check for leaks in the open line. Slight leakage is permissible, but significant leaks indicate worn packing.

- Repair and Recheck: If leaks are detected, remove and repair the defective cylinder. Reassess the circuit’s operation to ensure all issues are resolved, considering potential control valve leakage.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$32.00

$34.00

$35.00

$33.00

$35.00

$33.00

Reviews

There are no reviews yet.