Front Oil Seal Maintenance Guide

Product Overview

The front oil seal is a critical component that ensures the efficient functioning of your machinery by preventing oil leaks. Proper maintenance and timely replacement of the oil seal can greatly enhance the longevity and performance of your equipment. This guide provides detailed instructions for inspecting and maintaining the front oil seal, as well as solutions for common issues.

Key Features

- Efficient oil containment to prevent leaks

- Durable material for extended service life

- Compatible with various fan drive pulley systems

Benefits

- Maintains optimal engine performance

- Reduces the risk of equipment damage due to oil leaks

- Enhances overall equipment longevity

Usage Recommendations

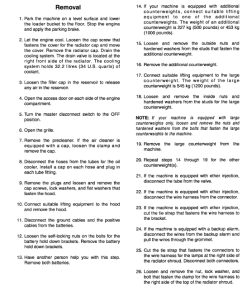

- Regularly inspect the front oil seal for any signs of damage or wear.

- If the seal shows signs of damage, it should be replaced immediately to prevent oil leaks.

- If the seal is in good condition, ensure that the contact surface on the fan drive pulley is smooth and free from scratches or roughness.

- In case of surface damage, use brazing to build up the damaged area, reshape it to specified dimensions, and polish carefully.

- An alternative repair method involves turning down the surface diameter and applying a steel sleeve, then finishing to the original specifications and polishing carefully.

- Ensure that no sharp edges are present after any repair, to avoid damaging the seal during assembly.

- If belt surfaces on the pulley are damaged, replace the entire pulley promptly.

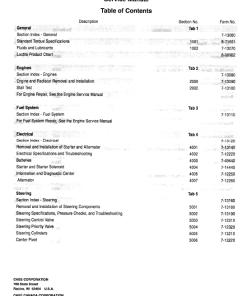

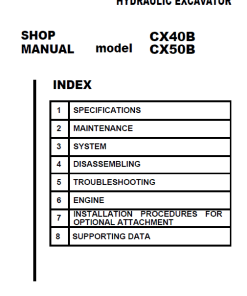

For detailed specifications and additional guidance, refer to the respective sections: General Specifications, Engine, Fuel System, Torque Converter, Transmission, Final Drive System, Track System, Electrical System, and Hydraulic System.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.50

$34.00

$34.00

$33.00

$34.00

$34.00

Reviews

There are no reviews yet.