Track Tension Adjustment Guide

Overview

Maintaining the correct track tension is crucial for the optimal performance and longevity of your machinery. Incorrectly adjusted track chains can either climb sprocket teeth and jump under heavy loads if too loose, or cause excessive wear on pins, bushings, and front idler bearings if too tight. This guide provides steps to properly adjust track tension, ensuring your equipment operates smoothly and efficiently.

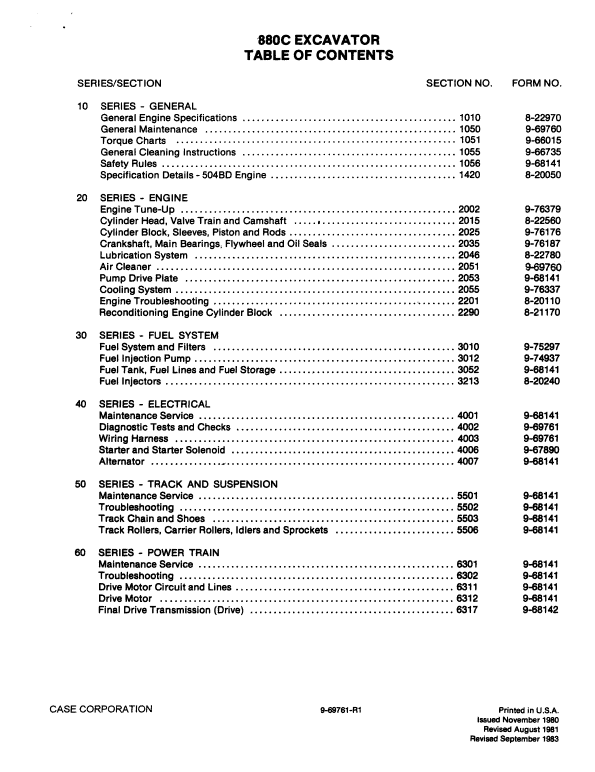

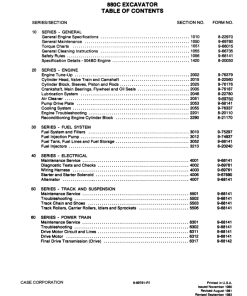

Table of Contents

- General

- Engines

- Fuel System

- Electrical

- Track and Suspension

- Power Train

- Brake System

- Equipment Hydraulics

- Mounted Equipment

Key Features

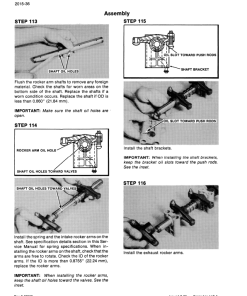

- Comprehensive step-by-step track tension adjustment process.

- Ensures optimal chain alignment and operation.

- Reduces maintenance costs by preventing undue wear and tear.

Benefits

- Prolongs the service life of your machinery components.

- Promotes stability and safety during machine operation.

- Prevents operational delays caused by improperly adjusted tracks.

Usage Recommendations

- Always check track tension on a hard surface for accuracy.

- Drive the unit to remove any slack from underneath the machine.

- Use a straight edge across the sag in the track, between the drive sprocket and the top rear roller, measuring the distance from the bottom of the straight edge to the top of the track at its lowest point.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$33.00

$33.00

$34.00

$34.00

$33.00

$34.00

Reviews

There are no reviews yet.