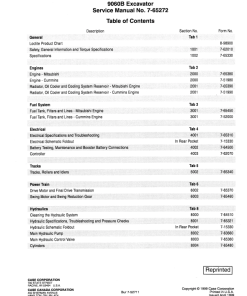

Case 9060B Excavator Service Manual

$34.00

This comprehensive Service Manual for the Case 9060B Excavator is your go-to resource for maintenance and repair, spanning 803 pages in PDF format.

Brand: Case

Model: 9060B

Type: Excavator

Manuals: Service Manual

Publication Numbers: 7-52711 (Apr 1999)

Language: English

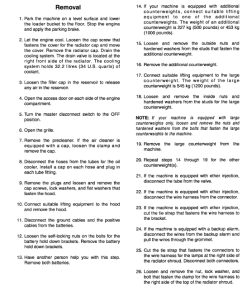

Manual Extract Arm Cylinder

Product Overview

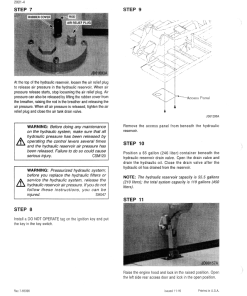

The Arm Cylinder Manual provides detailed instructions for the installation and maintenance of the arm cylinder system and its components. This comprehensive guide ensures proper assembly and troubleshooting, leading to optimal performance and reliability.

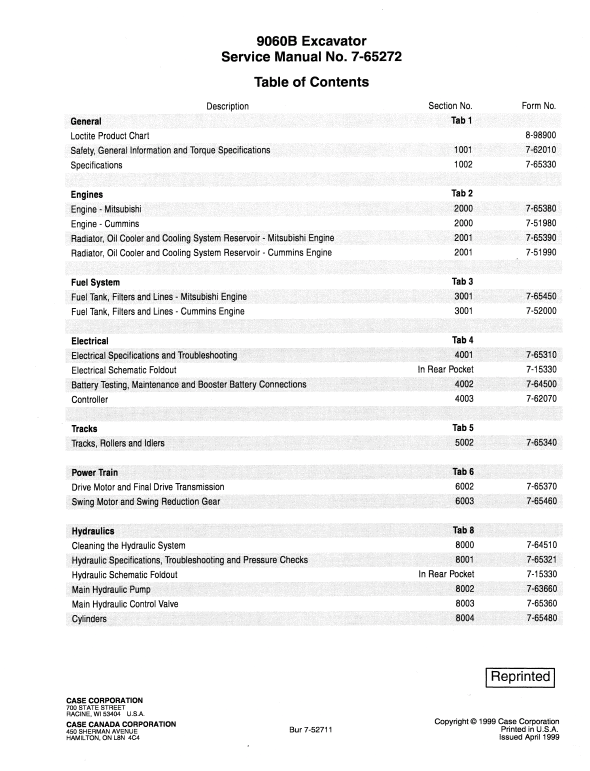

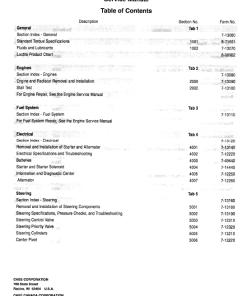

Table of Contents

- Specification

- Maintenance

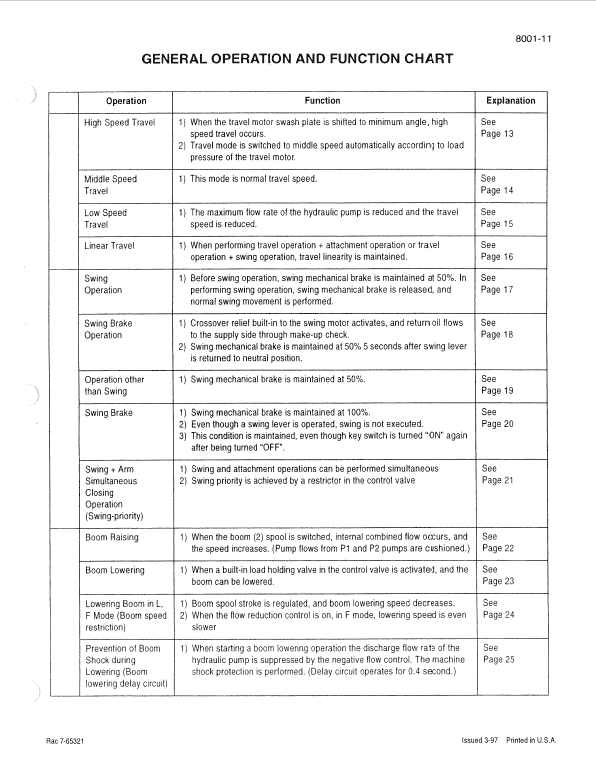

- System

- Disassembling

- Troubleshooting

- Engine

- Installation Procedures for Optional Attachments

Installation Instructions

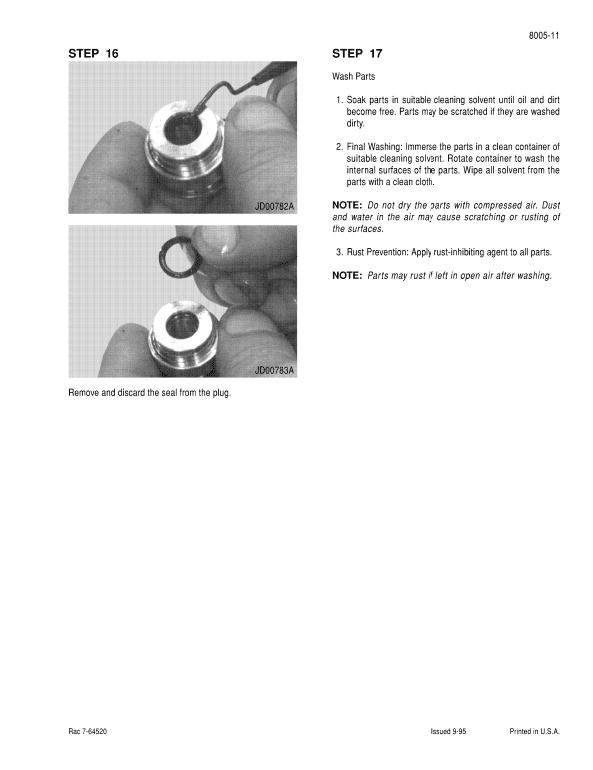

Please note: The numbers in parentheses in the following steps correspond to the Arm Cylinder illustration on page 38 of the manual.

-

Install the clamp (13) on the cylinder and secure it with the cap screw (11) and washer (12).

Tightening Torque: 25 lb-ft (32 Nm). -

Install the hydraulic tubes (5) in the clamp (9). Secure the clamp with the lock washer (8) and cap screw (7).

Tightening Torque: 31 lb-ft (51 Nm). -

Fit two new O-rings (6) onto the cylinder. Connect the two tubes (5) to the cylinder and secure with eight socket head cap screws (4).

Tightening Torque: 72 lb-ft (92 Nm). -

Install a new O-ring (3) at the end of the tube. Install the plug (2) into the end of the tube.

Tightening Torque: 176 lb-ft (226 Nm). - Install the lubrication fitting (1) on the cylinder to ensure consistent and proper lubrication.

Key Features

- Comprehensive instructions for assembly and maintenance.

- Easy-to-follow steps with accompanying illustrations.

- Detailed torque specifications for secure assembly.

Benefits

- Ensures safe and effective installation.

- Provides troubleshooting guidance for improved reliability.

- Enhances the longevity of the cylinder system with proper maintenance practices.

Usage Recommendations

- Ensure all part numbers and positions correlate with the manual’s diagrams before installation.

- Regularly inspect and maintain the cylinder to prevent wear and tear.

- Consult a qualified technician for advanced troubleshooting and repairs.

Only logged in customers who have purchased this product may leave a review.

Related products

$34.00

$34.00

$34.00

$34.00

$33.00

$34.00

$35.00

Reviews

There are no reviews yet.