Service Manual: Table of Contents

Product Overview

This comprehensive service manual provides detailed sections covering various aspects of equipment maintenance and repair. It is an essential guide for technicians and engineers, offering step-by-step instructions and insights to ensure efficient and effective operations.

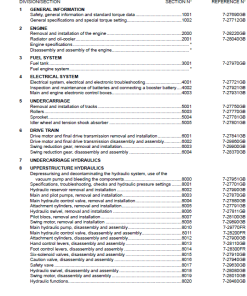

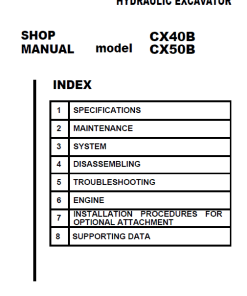

Table of Contents

- General

- Electrical

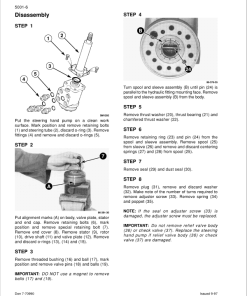

- Steering

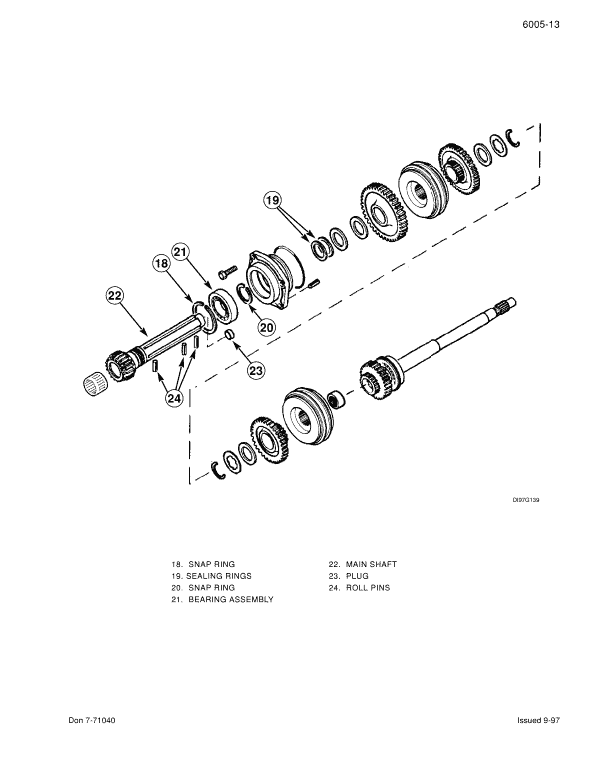

- Transmission

- Hydraulics

- Chassis and Mounted Equipment

Hydraulic Pump Efficiency

Test Connections

To test the hydraulic pump efficiency, follow these steps:

- Remove the flow divider and spring, then install the flow divider cap.

- Disconnect the hitch supply tube.

- Disconnect the power steering supply tube and cap the MCV fitting.

- Connect the flowmeter inlet to the hitch supply fitting from the MCV.

- Connect the flowmeter outlet to the transmission filler.

Test Requirements

- Heat the hydraulic oil to 49u00b0C (120u00b0F).

- Run the engine at rated speed and record the flow as ‘Flow A’.

- Adjust the load valve on the flowmeter to achieve a pressure of 137.9 bar (2000 psi), then record this as ‘Flow B’.

- Calculate pump efficiency using the formula: Flow ‘B’ / Flow ‘A’ x 100 = % Efficiency.

- Efficiency must not be less than 80%.

- If efficiency is less than 80%, consult the possible causes list below.

Pump Efficiency Calculation Example

Example Calculation:

If Flow A is 50 U/min and Flow B is 47 U/min, the efficiency calculation would be:

47 / 50 x 100 = 94%

Possible Causes of Low Pump Flow

- Low hydraulic oil level (potentially due to a faulty transfer pump).

- Blocked hydraulic filter in the MCV.

- Air intake around the filter bowl.

- Failure of the pump drive gear key.

- Damaged seals between the pump and the MCV.

- Blocked pump inlet in range housing.

- Worn pump components.

For further details, refer to the Multi Control Valve and Hydraulic Pump, Section 8010 of the manual.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$34.00

$34.00

$33.00

$34.00

$33.00

$34.00

Reviews

There are no reviews yet.