Case CX160B, CX180B Crawler Excavator Service Manual

$35.00

Enhance your maintenance skills with the New Holland CX160B, CX180B Excavator Service Manual. This comprehensive guide includes 1548 pages and an additional 535 pages of detailed instructions.

Brand: New Holland

Models: CX160B, CX180B

Type: Excavator and Schematic Set Excavator

Publication Numbers: 87637607 NA (Mar 2007), SM160BTOC (July 2009)

Language: English

Format: PDF

Flow Measurement Procedure for Hydraulic Systems

Product Overview

This guide provides a systematic approach for conducting flow measurements in hydraulic systems, specifically focusing on ensuring appropriate worker deployment and step-by-step instructions for effective operation and safety.

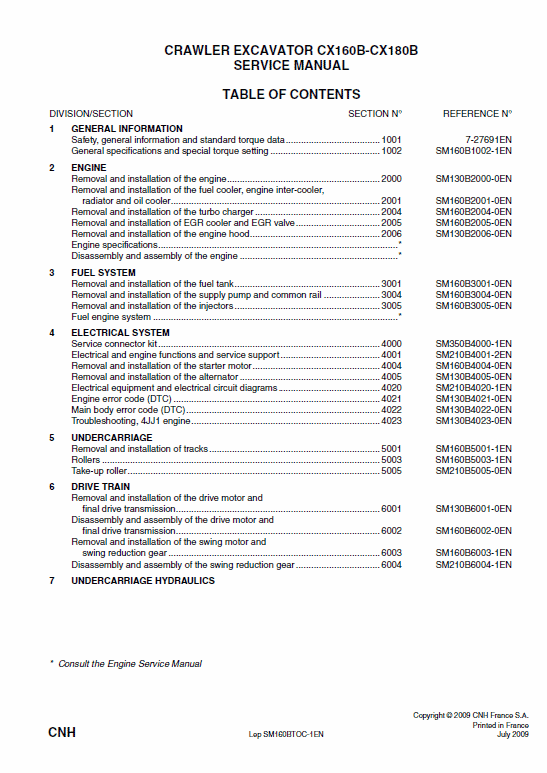

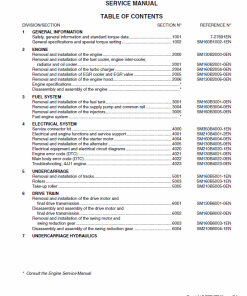

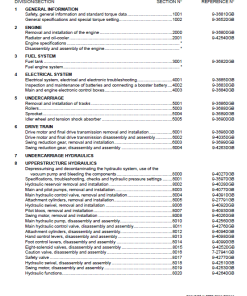

Table of Contents

- General Information

- Engine

- Fuel System

- Electrical System

- Undercarriage

- Drive Train

- Undercarriage Hydraulics

- Upper Structure Hydraulics

- Upper Structure

Key Features

- Comprehensive step-by-step flow measurement process.

- Detailed roles and responsibilities for each worker involved.

- Safety guidelines for maintaining appropriate hydraulic pressure levels.

Benefits

- Ensures accurate flow and pressure measurement for optimal system performance.

- Improves safety by clearly defining roles and expected actions during the procedure.

- Helps maintain hydraulic systems within safe operating limits.

Usage Recommendations

- Ensure all personnel are briefed on their roles: Work Supervisor, Operator, and Measurement Recorder.

- Monitor hydraulic oil temperature and engine performance for smooth operations.

- Adhere to pressure limits to prevent damage to equipment and ensure safety.

Flow Measurement Process

Manual Extract: Flow measurement

- Position the workers as specified:

- Worker 1: Work supervisor, responsible for pressure adjustment.

- Worker 2: Operator.

- Worker 3: Records flow and pressure measurement.

- Check the hydraulic oil temperature on the monitor (50u00b0C, 122u00b0F) and ensure normal engine rotation and pump current.

- Operator signals the arm-out relief operation to Worker 1.

- Worker 2 lowers the arm-out port relief with a minimum pressure of 24 MPa (240 bar, 3481 Psi) (P1 + P2).

- Initiate flow measurement process.

- Conduct arm-out relief operation.

- Record data measured in increments of 2.0 MPa (20 bar, 290 Psi) from 24.0 to 76.0 MPa (240 to 760 bar, 3481 to 11023 Psi), ending at maximum pressure.

- Remove the flow meters before exceeding the pressure gauge’s maximum pressure (40 MPa, 400 bar, 5802 Psi).

- Reset the arm-in port relief valve to its normal pressure setting, consulting the “Pressure Adjustment” section for details.

- Remove all pressure gauges and additional equipment, restoring the system to normal operations.

For reference, view the setup in the image below:

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.