Hydraulic System Manual

Product Overview

This manual provides essential guidance on the management and maintenance of hydraulic systems. It covers various aspects critical to ensuring optimal system performance and longevity. Proper handling and regular cleaning are crucial to prevent contamination, which can lead to system malfunction and inefficiencies.

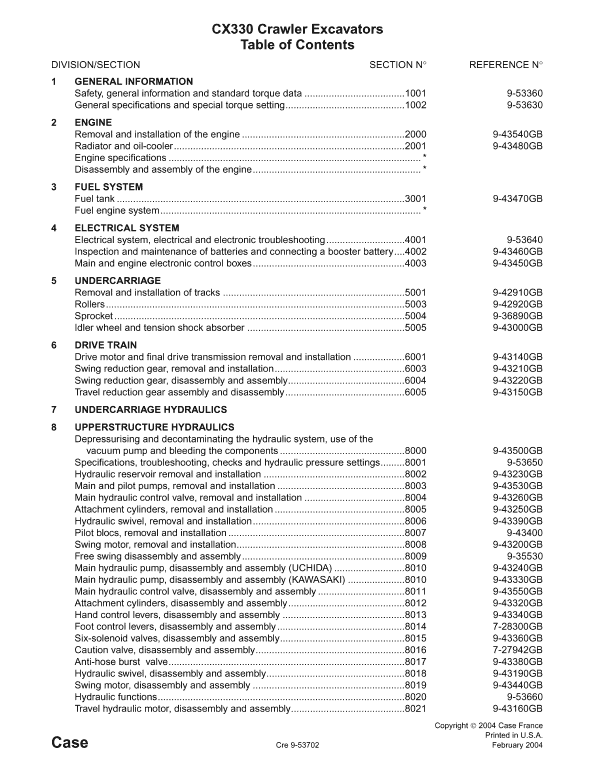

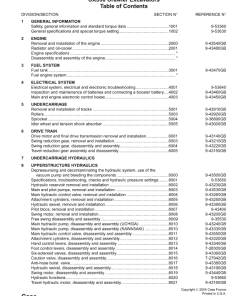

Table of Contents

- General Information

- Engines

- Fuel System

- Electrical System

- Undercarriage

- Drive Train

- Hydraulics

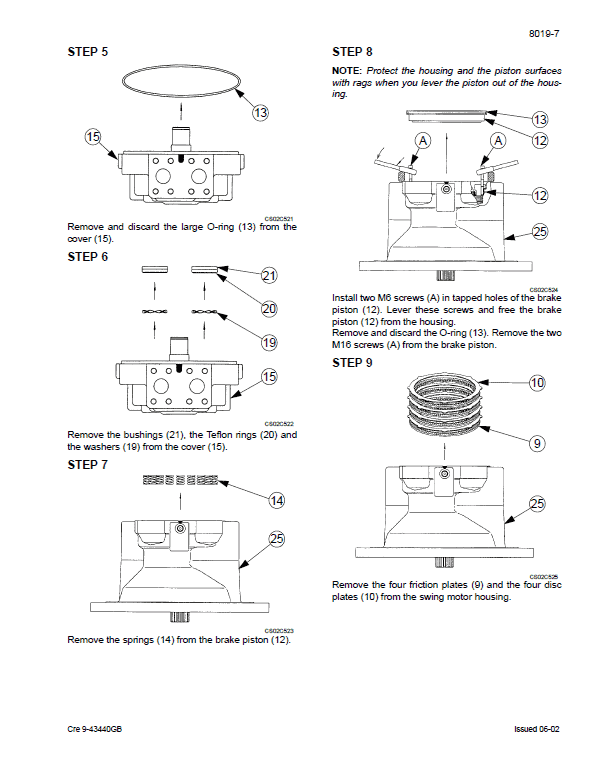

- Upper Structure

Cleaning the Hydraulic System

Contamination within hydraulic systems is a predominant cause of malfunction in hydraulic components. This contamination occurs due to foreign bodies in the hydraulic fluid and can take place in scenarios such as:

- Draining the fluid or reconnecting hydraulic lines.

- Removing components.

- Normal wear and tear of components.

- Damaged or worn seals.

- Damage to a component within the hydraulic system.

Key Features

- Designed to manage slight contamination naturally.

- Components engineered for minimal contamination tolerance.

- Portable filter compatibility with model CAS 10162A.

Benefits

- Prevents common problems associated with contaminated systems, such as leakage and inefficient valve operations.

- Enhances the durability and reliability of hydraulic components.

- Ensures the effective operation of safety mechanisms.

- Maintains optimal hydraulic fluid temperature and system power.

Usage Recommendations

To maintain system efficiency and prevent excessive contamination, it is imperative to:

- Regularly inspect and replace worn seals and components.

- Employ the portable filter CAS 10162A for purification when cleaning.

- Monitor system performance and address contamination symptoms promptly.

Only logged in customers who have purchased this product may leave a review.

Related products

$32.00

$33.00

$34.00

$34.00

$33.50

$35.00

$34.00

Reviews

There are no reviews yet.