Case CX350B, CX370B Crawler Excavator Service Manual

$35.00

Manual Included:

– Service Manual: 1484 pages

Specifications:

– Brand: New Holland

– Model: CX350B, CX370B

– Type: Excavator

– Manuals: Service Manual

– Publication Numbers: 47945155 (Nov 2015)

– Language: English

– Format: PDF

Table of Contents

- General Information

- Engine

- Fuel System

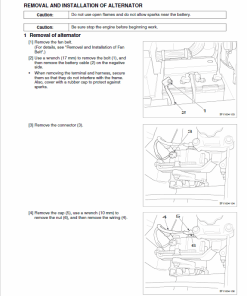

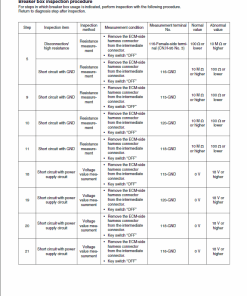

- Electrical Systems

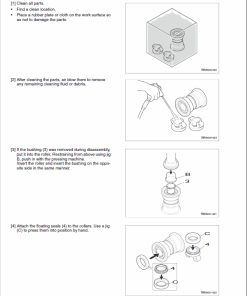

- Undercarriage

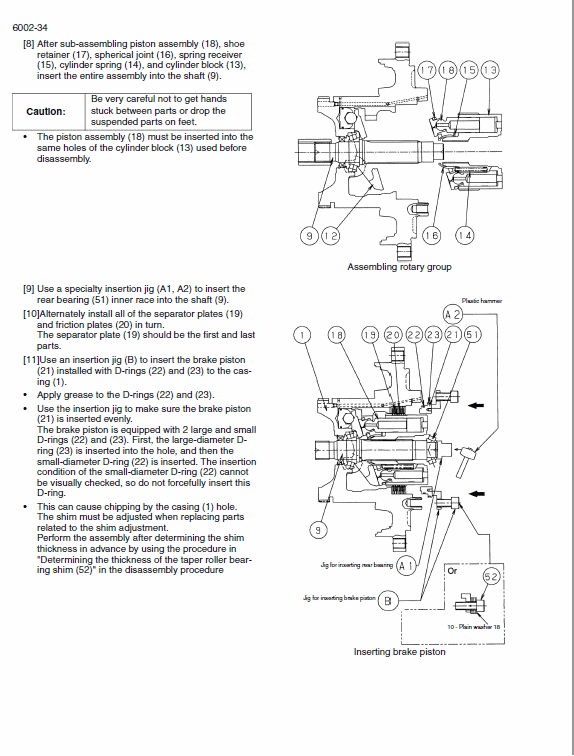

- Drive Train

- Upper Structure Hydraulics

- Upper Structure

- Hydraulic Schematics

- Electrical Schematics

Product Overview: Pressure Boost Control

The Pressure Boost Control system enhances operational efficiency by automatically adjusting the hydraulic pressure based on load conditions. This sophisticated mechanism ensures optimal performance, especially during high-demand tasks.

Key Features

- Dynamic Boost Control: Automatically increases main relief valve pressure from 34.3 MPa to 36.8 MPa when high-load conditions are detected.

- Mode-Specific Control: In SP or H work modes, the boost activates for up to 8 seconds. In contrast, the A work mode allows for continuous pressure boosting without time restrictions.

- Sensitive Load Detection: The system is adept at monitoring engine load ratios and pump pressures to activate boost when necessary.

- Operation-Triggered Boost Suspension: Automatically halts boost when certain conditions, such as operation stops, are met.

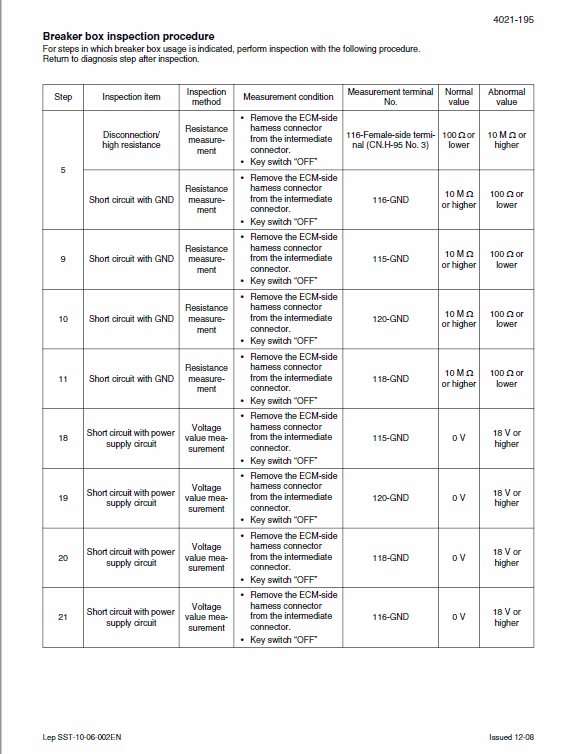

- Travel and Breaker Restrictions: Prohibits boosting when travel sensor is on or during breaker use, ensuring safety and equipment integrity.

Benefits

- Enhanced Performance: Ensures machinery operates efficiently under varying load conditions, maximizing productivity.

- Energy Efficiency: Adjusts pressure dynamically to prevent unnecessary energy consumption.

- Increased Equipment Lifespan: System intelligently manages pressure to reduce wear and tear on hydraulic components.

Usage Recommendations

- Optimal Work Modes: Utilize SP or H modes for temporary boosts and A mode for continuous boosting when necessary.

- Monitor Load Conditions: Ensure engine and pump pressures are within operational parameters for maximum system effectiveness.

- Avoid Prohibited Conditions: Disable boost during travel or breaker operations to maintain system safety.

Only logged in customers who have purchased this product may leave a review.

Related products

$33.50

$33.00

$35.00

$34.00

$34.50

$34.00

Reviews

There are no reviews yet.