Case DV36, DV45, DV45CC Roller Service Manual

$34.00

Type: Vibratory Roller and Combination Roller

Brand: New Holland

Model: DV36, DV45 Tier 4A (interim), DV45CC Tier 4A (interim)

Manual: Comprehensive service manual with 527 pages

Publication Number: 48142070 (Published Sep 2017)

Language: English

Format: PDF

Comprehensive Guide to Material Compaction

Product Overview

This comprehensive guide provides essential insights into evaluating stiffness reference values for cold minerals and asphalt during compaction processes. Understanding and monitoring these values are crucial for achieving optimal compaction and ensuring a high load-bearing capacity.

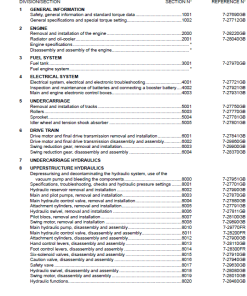

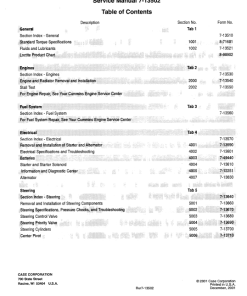

Table of Contents

- Content

- Introduction

- Maintenance

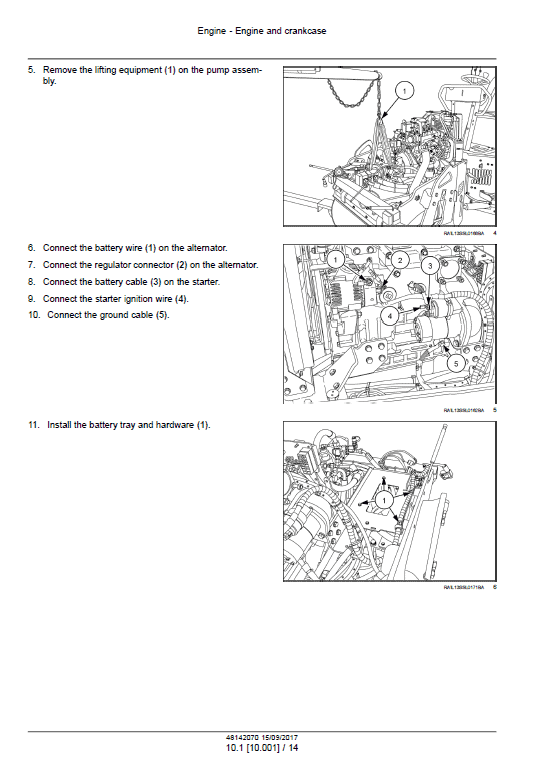

- Engine

- Hydrostatic Drive

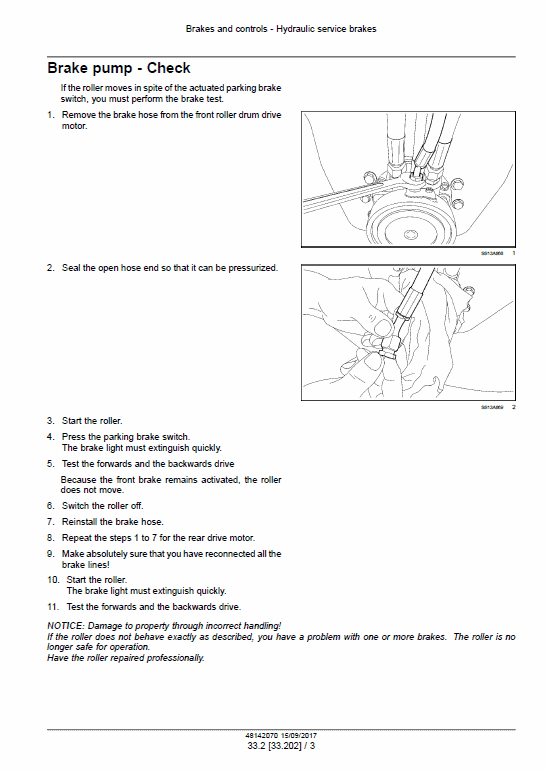

- Brakes and Controls

- Hydraulic System

- Frames and Ballasting

- Steering

- Wheels

- Electrical System

- Tools

- Platform, Cab, Bodywork and Decals

Manual Extract: Compacting – Stiffness Reference Values

Cold Minerals: To properly evaluate the kB values for sub-grade roads, consider the following guidelines:

- A sub-grade for a main road or motorway should aim for a stiffness value up to 100 kB.

- On a gravel surface, a stiffness value greater than 80 kB is considered good.

- For gravel layers within a pavement structure or frost sub-base, target stiffness values between 50 kB and 80 kB.

- Expect values below 50 kB in clayish, sandy, or wet grounds after removing the humus layer.

Asphalt: The stiffness of asphalt varies with temperature:

- Stiffness increases as the pavement cools.

- Compaction should occur within the temperature range of 140 u2013 80 u00b0C (284 u2013 176 u00b0F) for optimal results.

Benefits of Monitoring kB Values

- Indicator of Compaction Efficiency: An increasing kB value means ongoing compaction and improved load-bearing capacity.

- Optimal Compaction Point: When the kB value stabilizes or decreases, it indicates the material has reached its optimal stiffness, signaling the ideal stopping point for compaction efforts.

Usage Recommendations

- Regularly monitor kB values during compaction to ensure material integrity.

- Adjust compaction efforts based on real-time feedback from stiffness measurements.

- Employ best practices for different materials to achieve desired stiffness and durability.

Understanding and applying these principles will enhance the quality and longevity of your compaction projects.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.