Case DX48, DX55, DX60 Tractor Service Manual

$36.00

This comprehensive service manual for Case tractors, models DX48, DX55, and DX60, is an essential resource for maintenance and repair. The manual spans 1068 and 1438 pages, providing detailed instructions for troubleshooting and servicing.

Brand: Case

Model: DX48, DX55, DX60

Type: Tractor

Manuals Included: Service Manual

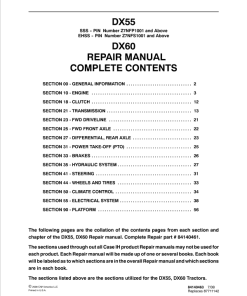

Publication Numbers: 87367137 (Aug 2005), 84140463 (Jul 2008)

Language: English

Format: PDF

Crankshaft Main Bearing and Thrust Washer: Removal and Inspection Guide

Product Overview

This guide provides a comprehensive overview of the process for removing and inspecting the crankshaft main bearing and thrust washer, critical components ensuring the smooth operation of engine assemblies. Essential for maintenance of CASE DX series machines, this manual section details meticulous steps to achieve optimal performance and longevity of your equipment.

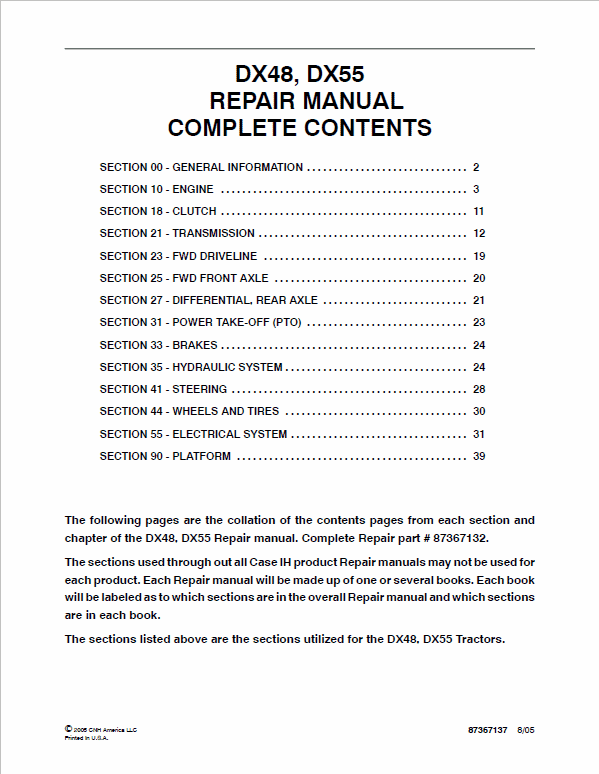

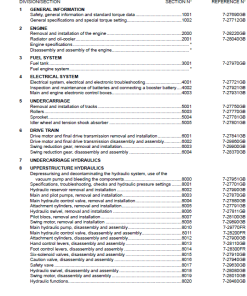

Table of Contents

- General

- Engine

- Clutch

- Transmission

- FWD Driveline

- Front Axle

- Rear Axle

- Power Take Off

- Brakes

- Hydraulic Systems

- Steering

- Wheels

- Cab Climate Control

- Electrical System

- Platform, Cab, Bodywork and Decals

Key Features

- Comprehensive step-by-step instructions for bearing and thrust washer maintenance.

- Specifications and measurements to ensure precision in repairs and adjustments.

- Applicable to a range of CASE DX models including DX48, DX55, and DX60.

Benefits

- Enhanced equipment performance through regular and precise maintenance.

- Prolonged machinery life by adhering to manufacturer specifications.

- Reduced risk of engine damage due to improper bearing wear or misalignment.

Usage Recommendations

- Ensure all necessary tools and the plastigauge are ready before starting the inspection.

- Carefully follow torque specifications when reinstalling components to avoid over-tightening.

- Regularly check thrust bearings for signs of wear, including poor contact or unusual wear patterns.

Manual Extract: Remedial Steps for Crankshaft Main Bearing and Thrust Washer

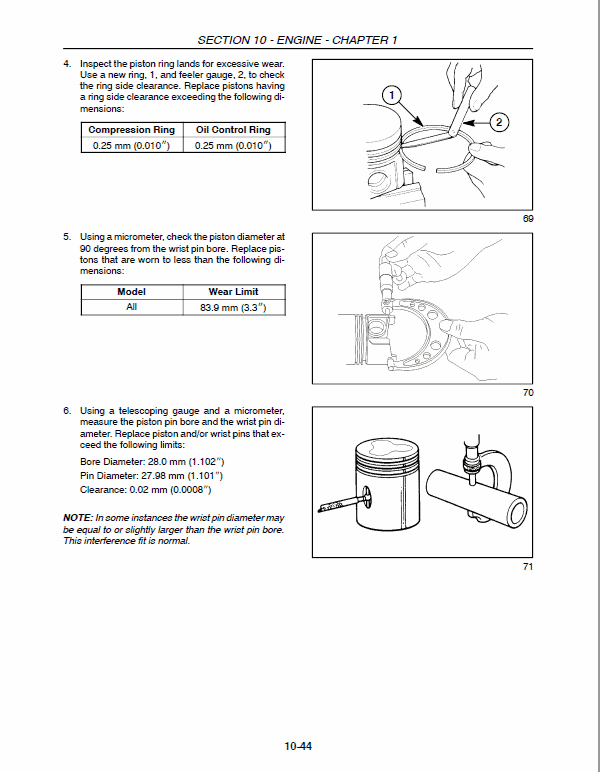

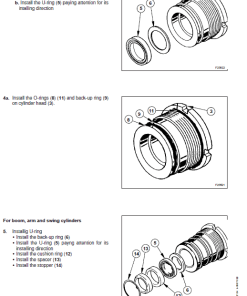

Follow these steps to effectively remove and inspect the components:

- Remove the two retaining bolts from the bearing holders.

- Take out the bearing holders and bearing liners.

- Position a piece of plastigauge across the bearing liners’ full width.

- Reinstall the bearing holder and tighten the bolts to between 49.0 – 53.9 Nu22c5m (36.2 – 39.8 ft. lbs.). Note: Avoid any rotation of the bearing holder.

- Remove the bearing holders and measure the width of the flattened plastigauge.

- Replace components or grind the crankshaft to the next undersize bearing as needed to secure the correct clearance.

- Inspect the thrust bearings for defects, measuring washer thickness with a micrometer. Replace washers if thickness is beyond allowable limits.

Standard Thickness: 2.95 mm-3.0 mm (0.116i-0.118i)

Allowable Limit: 2.8 mm (0.11i)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.